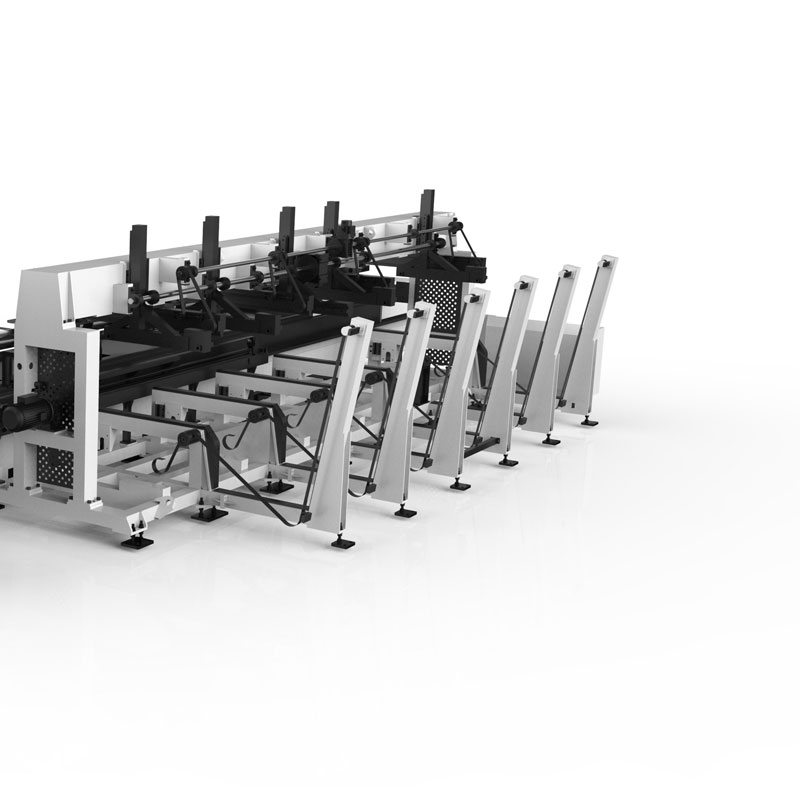

◆Adopt large floor boring and milling machine and use the whole processing method for precision processing to ensure the overall processing accuracy of the machine. ◆The up and down movement of the slider is controlled by two cylinders. The synchronization mechanism of slider adopts CNC servo pump to control synchronization, which is stable and reliable. ◆ Adopt German MT15 bending machine special CNC system to control Y X R axis. ◆In order to ensure the machining accuracy of the workpiece, the special European advanced technology CNC control, automatic adjustment of mechanical tie bar type deflection compensation table and V axis. ◆ Display the present and target position of X, R Y-axis and V-axis. ◆ There are manual, semi-automatic way and fully automatic way. ◆ The back stopping device has the function of automatic back avoidance and delayed action. The backstop device adopts high performance servo motor and precision ball screw and linear guide, so that the positioning accuracy of XR axis transmission and repeat positioning accuracy can be reliably guaranteed.

◆Adopt large floor boring and milling machine and use the whole processing method for precision processing to ensure the overall processing accuracy of the machine. ◆The up and down movement of the slider is controlled by two cylinders. The synchronization mechanism of slider adopts CNC servo pump to control synchronization, which is stable and reliable. ◆ Adopt German MT15 bending machine special CNC system to control Y X R axis. ◆In order to ensure the machining accuracy of the workpiece, the special European advanced technology CNC control, automatic adjustment of mechanical tie bar type deflection compensation table and V axis. ◆ Display the present and target position of X, R Y-axis and V-axis. ◆ There are manual, semi-automatic way and fully automatic way. ◆ The back stopping device has the function of automatic back avoidance and delayed action. The backstop device adopts high performance servo motor and precision ball screw and linear guide, so that the positioning accuracy of XR axis transmission and repeat positioning accuracy can be reliably guaranteed.CNC BENDING MACHINE

Discover precision and efficiency with our CNC bending machines. As a factory, we prioritize quality and excellence in every product we create. Experience the difference today.

Request a QuotePRODUCTS DETAILS

◆Adopt large floor boring and milling machine and use the whole processing method for precision processing to ensure the overall processing accuracy of the machine. ◆The up and down movement of the slider is controlled by two cylinders. The synchronization mechanism of slider adopts CNC servo pump to control synchronization, which is stable and reliable. ◆ Adopt German MT15 bending machine special CNC system to control Y X R axis. ◆In order to ensure the machining accuracy of the workpiece, the special European advanced technology CNC control, automatic adjustment of mechanical tie bar type deflection compensation table and V axis. ◆ Display the present and target position of X, R Y-axis and V-axis. ◆ There are manual, semi-automatic way and fully automatic way. ◆ The back stopping device has the function of automatic back avoidance and delayed action. The backstop device adopts high performance servo motor and precision ball screw and linear guide, so that the positioning accuracy of XR axis transmission and repeat positioning accuracy can be reliably guaranteed.

◆Adopt large floor boring and milling machine and use the whole processing method for precision processing to ensure the overall processing accuracy of the machine. ◆The up and down movement of the slider is controlled by two cylinders. The synchronization mechanism of slider adopts CNC servo pump to control synchronization, which is stable and reliable. ◆ Adopt German MT15 bending machine special CNC system to control Y X R axis. ◆In order to ensure the machining accuracy of the workpiece, the special European advanced technology CNC control, automatic adjustment of mechanical tie bar type deflection compensation table and V axis. ◆ Display the present and target position of X, R Y-axis and V-axis. ◆ There are manual, semi-automatic way and fully automatic way. ◆ The back stopping device has the function of automatic back avoidance and delayed action. The backstop device adopts high performance servo motor and precision ball screw and linear guide, so that the positioning accuracy of XR axis transmission and repeat positioning accuracy can be reliably guaranteed.Hot Products

Professional Tube Fiber Laser Cutting Machine

Handheld Laser Welding Machine

Economical Fiber Laser Cutting Machine

Laser Cleaning Machine

CNC router

Tube machine automatic loading and unloading device

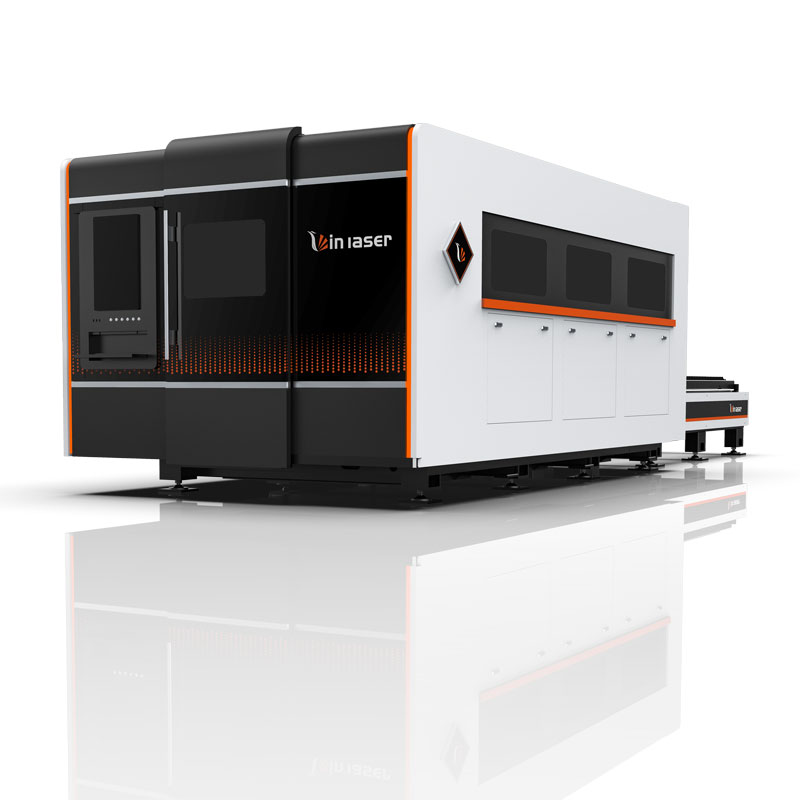

Whole cover&Exchange platform Fiber Laser Cutting Machine

CNC BENDING MACHINE

3 in 1 Laser Welding Cleaning and Cutting Machine

High power&Ultra-large format metal sheet fiber laser cutting machine

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours