Long equipment handle, good operation performance, single person under the table can complete the cleaning work, the whole machine is small in size, light weight, flexible and convenient operation.High cleaning efficiency, low cost, compared with the cost of regular replacement of blade, can save up to 75% of the cost through multiple cleaning.1. Start-up: place the equipment at an angle of 45° on the table, pay attention to the tool not to touch the slag and the work surface, start the power switch, keep the motor running normally 2. After visually aligning the tool in non-stop opening and closing motion with the rack to be cleaned, gently flatten the handle so that the weight of the equipment is completely on the table, that is, to start working 3. After starting the work, hold the handle and push the tool to make it move back and forth parallel to the rack direction to clean 4. When the cleaning work is completed, lift the equipment handle to 45° angle, turn off the handle power, you can stop the slag removal workCrossing the beam: When the equipment encounters the horizontal fence in the process of moving forward can not continue to move forward, press down the handle, let the equipment knife part of the suspension, to pass the cross-beam position, put the handle can be flat Change line: when the equipment can not continue to move forward in the process of encountering the horizontal fence, raise the handle, and then swing to the left (right) at a certain angle, aligned with the molten slag can be put down, without the operator on the table It is recommended that the equipment run continuously for 1 hour, with an interval break of 10-20 minutes to help maintain the service life of the machine

Long equipment handle, good operation performance, single person under the table can complete the cleaning work, the whole machine is small in size, light weight, flexible and convenient operation.High cleaning efficiency, low cost, compared with the cost of regular replacement of blade, can save up to 75% of the cost through multiple cleaning.1. Start-up: place the equipment at an angle of 45° on the table, pay attention to the tool not to touch the slag and the work surface, start the power switch, keep the motor running normally 2. After visually aligning the tool in non-stop opening and closing motion with the rack to be cleaned, gently flatten the handle so that the weight of the equipment is completely on the table, that is, to start working 3. After starting the work, hold the handle and push the tool to make it move back and forth parallel to the rack direction to clean 4. When the cleaning work is completed, lift the equipment handle to 45° angle, turn off the handle power, you can stop the slag removal workCrossing the beam: When the equipment encounters the horizontal fence in the process of moving forward can not continue to move forward, press down the handle, let the equipment knife part of the suspension, to pass the cross-beam position, put the handle can be flat Change line: when the equipment can not continue to move forward in the process of encountering the horizontal fence, raise the handle, and then swing to the left (right) at a certain angle, aligned with the molten slag can be put down, without the operator on the table It is recommended that the equipment run continuously for 1 hour, with an interval break of 10-20 minutes to help maintain the service life of the machineBlade cleaner

At Blade cleaner factory, we offer premium quality solutions to keep your blades clean and sharp. Say goodbye to rust and dirt with our unbeatable products!

Request a QuotePRODUCTS DETAILS

Long equipment handle, good operation performance, single person under the table can complete the cleaning work, the whole machine is small in size, light weight, flexible and convenient operation.High cleaning efficiency, low cost, compared with the cost of regular replacement of blade, can save up to 75% of the cost through multiple cleaning.1. Start-up: place the equipment at an angle of 45° on the table, pay attention to the tool not to touch the slag and the work surface, start the power switch, keep the motor running normally 2. After visually aligning the tool in non-stop opening and closing motion with the rack to be cleaned, gently flatten the handle so that the weight of the equipment is completely on the table, that is, to start working 3. After starting the work, hold the handle and push the tool to make it move back and forth parallel to the rack direction to clean 4. When the cleaning work is completed, lift the equipment handle to 45° angle, turn off the handle power, you can stop the slag removal workCrossing the beam: When the equipment encounters the horizontal fence in the process of moving forward can not continue to move forward, press down the handle, let the equipment knife part of the suspension, to pass the cross-beam position, put the handle can be flat Change line: when the equipment can not continue to move forward in the process of encountering the horizontal fence, raise the handle, and then swing to the left (right) at a certain angle, aligned with the molten slag can be put down, without the operator on the table It is recommended that the equipment run continuously for 1 hour, with an interval break of 10-20 minutes to help maintain the service life of the machine

Long equipment handle, good operation performance, single person under the table can complete the cleaning work, the whole machine is small in size, light weight, flexible and convenient operation.High cleaning efficiency, low cost, compared with the cost of regular replacement of blade, can save up to 75% of the cost through multiple cleaning.1. Start-up: place the equipment at an angle of 45° on the table, pay attention to the tool not to touch the slag and the work surface, start the power switch, keep the motor running normally 2. After visually aligning the tool in non-stop opening and closing motion with the rack to be cleaned, gently flatten the handle so that the weight of the equipment is completely on the table, that is, to start working 3. After starting the work, hold the handle and push the tool to make it move back and forth parallel to the rack direction to clean 4. When the cleaning work is completed, lift the equipment handle to 45° angle, turn off the handle power, you can stop the slag removal workCrossing the beam: When the equipment encounters the horizontal fence in the process of moving forward can not continue to move forward, press down the handle, let the equipment knife part of the suspension, to pass the cross-beam position, put the handle can be flat Change line: when the equipment can not continue to move forward in the process of encountering the horizontal fence, raise the handle, and then swing to the left (right) at a certain angle, aligned with the molten slag can be put down, without the operator on the table It is recommended that the equipment run continuously for 1 hour, with an interval break of 10-20 minutes to help maintain the service life of the machineHot Products

Economical Fiber Laser Cutting Machine

Laser Cleaning Machine

CO2 laser cutting and engraving machine

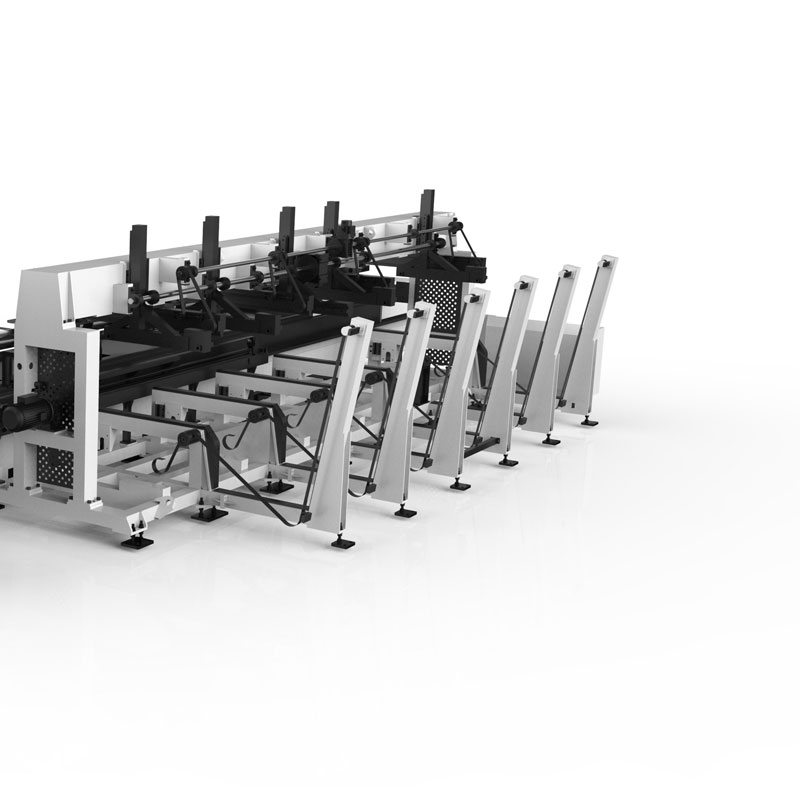

Tube machine automatic loading and unloading device

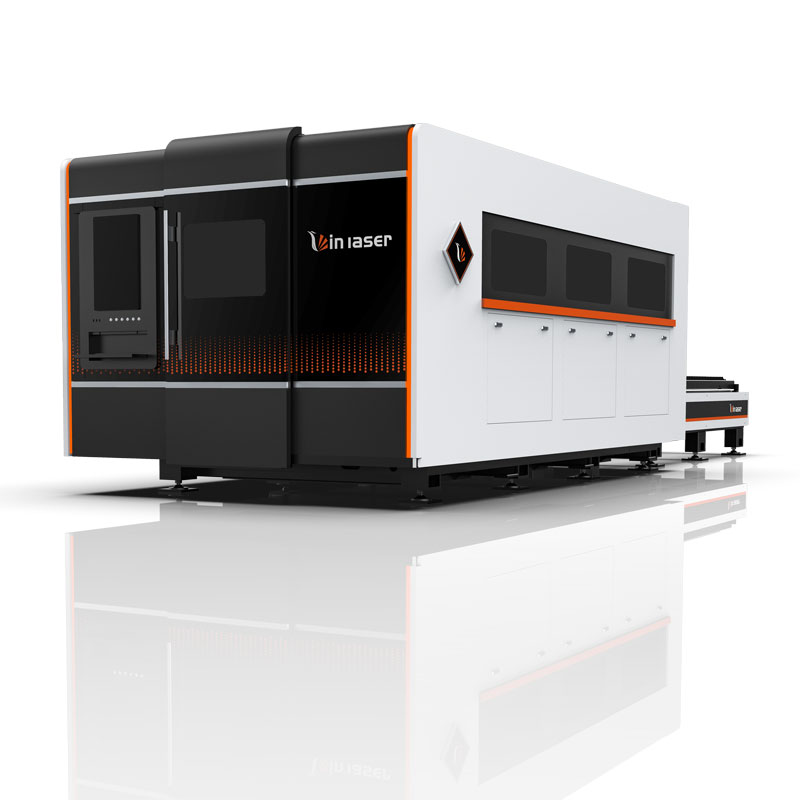

Whole cover&Exchange platform Fiber Laser Cutting Machine

Handheld Laser Welding Machine

CNC router

3 in 1 Laser Welding Cleaning and Cutting Machine

Automatic tower storage device for sheet metals

Sheet&Tube Dual-use Fiber Laser Cutting Machine

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours