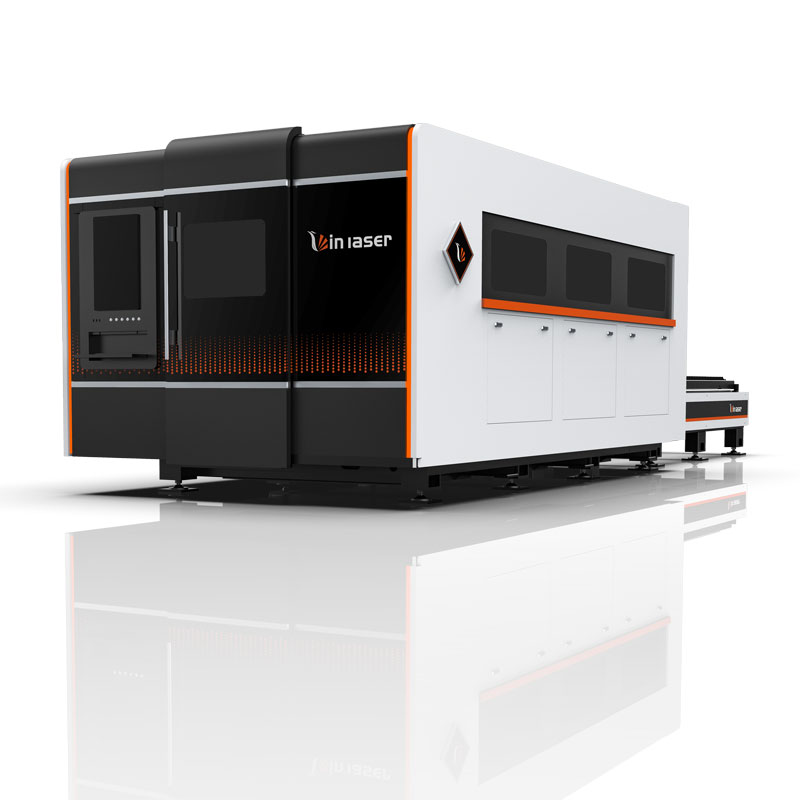

Powerful 3000w Laser: A Game-Changer in Industrial Technology

By:Admin

{Company Name} is a cutting-edge technology company that specializes in developing advanced solutions for various industries. With a strong focus on research and development, the company has consistently pushed the boundaries of innovation and has firmly established itself as a leader in the field of laser technology.

The Laser 3000w is the latest addition to {Company Name}'s impressive lineup of laser cutting machines. Boasting a cutting power of 3000 watts, this state-of-the-art machine is capable of precision cutting through a wide range of materials, including metal, plastic, and wood, with unparalleled speed and accuracy. The high power output of the Laser 3000w sets it apart from its predecessors, making it a highly sought-after tool for manufacturers looking to streamline their production processes and enhance their overall efficiency.

One of the key features of the Laser 3000w is its versatility. Equipped with advanced laser technology, the machine is not only capable of cutting through thick and dense materials with ease, but it also offers a high degree of flexibility, allowing for intricate and complex cuts to be made with precision. This makes it an ideal tool for a wide range of applications, from automotive and aerospace manufacturing to architectural and industrial design.

In addition to its cutting-edge technology, the Laser 3000w is also designed with user convenience in mind. The machine features an intuitive interface that allows for seamless operation, and its robust construction ensures long-term durability and reliability. With user-friendly controls and advanced safety features, the Laser 3000w is suitable for use in various industrial settings, providing a cost-effective and efficient solution for manufacturers looking to optimize their production processes.

{Company Name} has always been committed to delivering innovative solutions that meet the evolving needs of its customers, and the Laser 3000w is a testament to that commitment. With its unparalleled cutting power and versatility, this cutting-edge machine is set to redefine the standards of precision cutting and provide manufacturers with a competitive edge in their respective industries.

The introduction of the Laser 3000w is a significant milestone for {Company Name}, showcasing the company's dedication to pushing the boundaries of innovation and delivering groundbreaking solutions to its customers. As the demand for high-quality, efficient manufacturing processes continues to grow, the Laser 3000w is poised to make a lasting impact on the industry, setting a new benchmark for laser cutting technology.

In conclusion, the Laser 3000w represents a significant advancement in laser cutting technology, and {Company Name} is proud to be at the forefront of this innovation. With its powerful cutting capabilities, versatility, and user-friendly design, the Laser 3000w is set to revolutionize the manufacturing and industrial sectors, offering a cutting-edge solution for manufacturers looking to enhance their production processes and stay ahead of the competition. This latest invention from {Company Name} is poised to make a lasting impact on the industry, and the company looks forward to continuing its legacy of innovation and excellence in the field of laser technology.

Company News & Blog

Laser News: An Insight into the Revolutionary Co2 Laser Technology

Researchers at a leading technology company have developed a ground-breaking CO2 laser that promises to revolutionize the manufacturing industry. The laser, developed by a team at the company’s research laboratory, utilizes cutting-edge technology to offer unprecedented precision and efficiency. With its ability to cut and shape a wide variety of materials with supreme accuracy, this CO2 laser has the potential to transform numerous industries worldwide.Traditional lasers have long been used in manufacturing processes, but this new CO2 laser sets itself apart with its powerful capabilities. By utilizing a high-energy beam of light, this laser can effortlessly slice through materials such as wood, plastic, and metal. The precision of the CO2 laser is unmatched, ensuring that the end product is of the utmost quality while minimizing wastage. This breakthrough technology will enable manufacturers to produce intricate and complex designs with remarkable ease.The unique selling point of this CO2 laser lies in its intuitive controls and user-friendly interface. The laser’s operating system has been designed to be easily navigated, allowing operators to quickly adjust and optimize settings for different materials. This user-centric approach ensures that even those with minimal training can effectively utilize the CO2 laser, streamlining the manufacturing process and bolstering overall productivity. Furthermore, the laser is equipped with advanced safety features, mitigating any potential risks associated with laser use.In addition to its exceptional precision, this CO2 laser boasts remarkable speed and efficiency. It has been engineered to provide faster cutting speeds, reducing manufacturing time and costs. By incorporating advanced optics and an efficient laser tube, this cutting-edge technology is at the forefront of laser technology. Manufacturers can expect improved productivity and increased output, making this CO2 laser a highly desirable tool for a variety of industries.One of the key factors that sets this CO2 laser apart from its competitors is its environmental friendliness. While traditional lasers emit harmful emissions and pollutants during the cutting process, this CO2 laser significantly reduces the carbon footprint. Its innovative design allows for the efficient energy usage and sustainable operations, aligning with global efforts towards a greener future. By reducing waste and minimizing harmful emissions, manufacturers can contribute to the preservation of the environment while simultaneously ensuring the highest quality products.The market response to this CO2 laser has been overwhelmingly positive, with industry leaders eagerly adopting this cutting-edge technology. Manufacturers across various sectors, such as automotive, aerospace, and electronics, have lauded its superior capabilities and its potential to revolutionize their production processes. The versatility of this CO2 laser allows it to cater to the specific needs of each industry, making it a highly sought-after tool in the market.With its outstanding precision, efficiency, and environmental benefits, this CO2 laser marks a significant milestone in the manufacturing industry. It has the potential to reshape how manufacturers operate and streamline their production processes. As this innovative technology continues to evolve, it is anticipated that even greater advancements will be achieved, further cementing its position as an industry leader. The CO2 laser remains a testament to the ingenuity and dedication of the research team behind its development, and the positive impact it will have on manufacturing operations worldwide.

Tips to Avoid Machine Cutting Errors in Woodworking

Cutting machines have become an essential tool in the manufacturing industry, allowing businesses to cut materials quickly and efficiently. One popular cutting machine is the 1015 machine, which is known for its high precision cuts and versatility. However, even the most skilled operators can encounter problems when using a cutting machine, which can result in failed cuts or damages to the equipment.In this blog, we will discuss common mistakes that operators make when using a cutting machine, how to prevent them, and how to optimize your machine for maximum results.Mistake #1: Incorrect Material SetupOne of the most common mistakes that operators make when using a cutting machine like the 1015 is not setting up the material correctly. It might sound like a simple thing to do, but even a small mistake can cause significant problems. For example, if you don't adjust the material to the machine's specifications, you might end up with uneven or jagged cuts. This can lead to wasted materials and additional time and expenses to fix the errors.To prevent this from happening, make sure you read the manual and familiarize yourself with the machine's specifications. Next, ensure that you have the right tools and clamps to keep the materials securely in place. Finally, double-check the setup before you start cutting to ensure that everything is in the right place.Mistake #2: Using the Wrong BladeAnother common mistake is using the wrong blade for the materials you're cutting. For example, if you're cutting metal, you need a different blade than if you're cutting wood. Using the wrong blade can lead to dullness, chipping, and eventually damage to the machine itself.Before you start cutting, make sure that you have the right blade for the job. Research the blade types, sizes, and thicknesses suitable for the material you're cutting. Ensure that the blade is properly set up and lubricated for smooth and clean cuts.Mistake #3: Insufficient MaintenanceCutting machines require regular maintenance to keep them running at their best. However, many operators neglect this important step, which can cause several problems. For example, unchecked debris can build up and jam the machine, resulting in damage or subpar cuts.To prevent this, make sure that you have a maintenance schedule in place and follow it diligently. Regularly check for debris like sawdust or metal filings and clean the machine's mechanisms. Ensure that all the components are well lubricated and adjust any components that might have shifted or become loose.Mistake #4: Operator ErrorSometimes, the mistakes made when using a cutting machine are not related to the machine itself. Instead, operator error can cause damage, improper cuts, or wasted materials.To prevent this, make sure that you or your operators are well-informed and adequately trained in how to use the machine. Always keep safety in mind and wear protective equipment, such as goggles and gloves. Finally, ensure that the operator is focused and not distracted when using the machine.ConclusionThe Oliver Machinery 1015 Cutting Machine is an excellent tool for businesses looking to increase their efficiency and precision. However, ensuring the machine continues to perform at its best requires careful attention and maintenance. By avoiding common mistakes like incorrect material setups, using the wrong blades, insufficient maintenance, and operator error, you can ensure that your cutting machine works efficiently and delivers optimum results.In summary, whenever you experience problems with a cutting machine, take your time, review the above points, and make any necessary adjustments. Applying these best practices will help you optimize your cutting machine, extend its lifespan, and enjoy the benefits of increased efficiency and profitability in your business.

High-Quality Laser-Cut Steel Plate: The Ultimate Guide

Laser Cut Steel Plate Technology Revolutionizes Manufacturing IndustryIn recent years, the manufacturing industry has experienced a significant evolution in technology, leading to increased efficiency and precision. One of the most notable advancements in this industry is the introduction of laser cut steel plate technology. This cutting-edge technology has revolutionized the way steel plates are processed, allowing for unparalleled accuracy and speed in manufacturing processes.{Company Name} is at the forefront of this technological revolution, offering state-of-the-art laser cut steel plate services to a wide range of industries. With a commitment to innovation and excellence, {Company Name} has established itself as a leader in the field of precision metal fabrication.Laser cut steel plate technology utilizes high-powered lasers to cut through steel with remarkable precision. This advanced method allows for complex shapes and intricate designs to be achieved with absolute accuracy. In addition, laser cutting ensures clean and smooth edges, eliminating the need for additional finishing processes.{Company Name} has invested in cutting-edge laser cutting equipment, allowing them to offer a comprehensive range of steel plate cutting services. Whether for industrial machinery, architectural components, or automotive parts, {Company Name} caters to the diverse needs of their clients with precision and efficiency.The introduction of laser cut steel plate technology has significantly reduced lead times in manufacturing processes. With the ability to cut through thick steel plates at high speeds, {Company Name} is able to deliver orders in a timely manner, meeting even the most demanding deadlines.Furthermore, laser cutting technology has minimized material waste, as it allows for precise nesting and optimization of steel plates. This not only contributes to cost savings for manufacturers but also aligns with sustainable and eco-friendly manufacturing practices.With a team of skilled engineers and technicians, {Company Name} offers personalized support to clients, from the initial design phase to the final production of steel plate components. Their expertise in laser cutting technology ensures that clients receive top-quality products that meet their exact specifications.In addition to their commitment to precision and efficiency, {Company Name} places great emphasis on quality control and safety in their manufacturing processes. Their state-of-the-art facilities are equipped with the latest safety measures, ensuring a secure and controlled environment for laser cutting operations.As a company dedicated to continuous improvement, {Company Name} stays abreast of the latest advancements in laser cutting technology. They regularly invest in training and development, ensuring that their team remains at the forefront of industry trends and best practices.The adoption of laser cut steel plate technology has had a profound impact on the manufacturing industry, offering a level of precision and efficiency that was previously unattainable. {Company Name} has embraced this technology, leveraging it to provide unparalleled cutting services to their clients across various industries.In conclusion, the introduction of laser cut steel plate technology has transformed the manufacturing landscape, and {Company Name} is leading the charge in delivering exceptional precision and efficiency to their clients. With a focus on innovation, quality, and customer satisfaction, {Company Name} remains a trusted partner for all steel plate cutting needs.

Commercial & Industrial Vehicles & Machinery for Contractors & Construction Equipment in Sunnyside, WA | Discover Top Businesses, Reviews and Recommendations on CitySquares

article:Construction Equipment Market Witnesses Significant Growth in Sunnyside, WAThe construction industry in Sunnyside, WA is showing promising growth, with an increasing demand for commercial and industrial vehicles and machinery. This trend has resulted in a surge in the number of businesses offering contractors and construction equipment in the area.One of the top companies providing such services is located in Sunnyside, WA and is making a significant impact in the market. The company has been providing a wide range of commercial and industrial vehicles and machinery to contractors and construction companies for many years, and they have become a reliable source within the industry.The growth in Sunnyside's construction industry has been primarily driven by infrastructure development initiatives, such as the government’s focus on increasing the number of roads and bridges across the state. This has resulted in an upsurge in demand for construction equipment including bulldozers, excavators, cranes, and road rollers.Apart from that, another major factor contributing to the increase in the demand for commercial and industrial vehicles and machinery is the growing number of large-scale construction projects taking place in the area. These projects include the construction of high-rise buildings, housing complexes, and commercial spaces.The company offering contractors and construction equipment in Sunnyside, WA, has been providing their services to many of these high-profile construction projects, which has played a significant role in their success. Their expertise and deep knowledge of the construction industry have made them a go-to source for many contractors and construction companies in the area.In addition to their quality services, the company is also known for their exceptional customer service and flexibility. They work closely with their clients to understand their needs and requirements and provide customized solutions that meet their specific demands.The company has been able to maintain a competitive edge in the market due to their commitment to quality and their extensive range of products. They have a large inventory of commercial and industrial vehicles and machinery to choose from, including some of the most popular brands in the industry.Furthermore, the company has invested heavily in top-of-the-line technology to ensure their equipment is up-to-date, well-maintained, and ready for use. This has helped clients to achieve their targets in a timely and efficient manner, further establishing the company's credibility in the industry.Overall, the growth in Sunnyside's construction industry is showing no signs of slowing down, and the demand for commercial and industrial vehicles and machinery is expected to continue to rise in the coming years. With the expertise, product range, and technology offered by companies like this, Sunnyside's construction industry can continue to expect great things.In conclusion, the construction industry in Sunnyside, WA, is a booming industry with much potential for growth. With the help of companies offering contractors and construction equipment, local construction projects are well-equipped to achieve their goals in a timely and efficient manner. The industry is optimistic about its potential, and the companies servicing them are aiming to make it an even more successful one.

New Smart Factory Increases Production Capacity by 30% with Automated Equipment

DFI's New Smart Factory Brings Innovation to Industrial ComputingDFI, the world's leading brand in embedded motherboards and industrial computers, recently unveiled their new smart factory. The factory is packed with cutting-edge automated equipment, and the company believes this will improve their production capacity by up to 30%.The new smart factory, located in Taiwan, includes a range of cutting-edge automated equipment. These include advanced machines for cutting, drilling, milling, assembly, testing, and packaging. The company says that these innovations will improve both quality and efficiency.According to DFI spokespersons, the company has designed the smart factory to be flexible, scalable, and sustainable. For instance, the factory boasts modular designs that enable fast reconfigurations and easy upgrades. The factory is also equipped with advanced sensors that can monitor critical factors such as temperature, humidity, energy usage, and safety.DFI's smart factory is capable of processing orders promptly and efficiently. The factory has an automatic material handling system that simplifies the movement of goods throughout the production process. The production line can also produce customized orders with minimal changeover times.DFI believes that with the new smart factory, they will enhance the quality of their products while maintaining the highest standards of safety and sustainability. The company has achieved this by incorporating Industry 4.0 principles, which focus on interconnecting machines, digitization, and data analytics.The introduction of the smart factory is good news for DFI's customers. The factory will give the company the ability to produce more robust and reliable embedded motherboards and industrial computers. This, in turn, will help customers who rely on DFI's products for their operations.DFI's new smart factory also improves its competitiveness in the global market. As a leader in industrial computing, DFI's products are used in various sectors, including healthcare, transportation, automation, and manufacturing. With the smart factory, DFI can increase its production capacity and process orders more quickly.The smart factory will also boost DFI's sustainability efforts. Automated equipment will reduce the use of manual labor, minimizing the factory's carbon footprint. Furthermore, the factory's sensors will allow the company to monitor energy usage and optimize efficiency without compromising quality.During the factory's inauguration, DFI invited the media to tour the facility. Reporters were able to witness the factory's advanced equipment and the company's dedication to advancing computing technologies. The attendees were impressed by the new facility and the cutting-edge technologies that it integrated.In conclusion, DFI's new smart factory is a significant milestone for the company. With state-of-the-art automated equipment, DFI can produce more robust and reliable embedded motherboards and industrial computers. The smart factory will improve the quality and efficiency of DFI's production process, and enhance the company's competitiveness in the global market. Moreover, the factory's sustainability features align with DFI's commitment to environmental responsibility and social progress.

Sheet/Plate and Tube/Pipes Laser Cutting Machines: Advanced Solutions for Laser Cutting

Title: Advancements in Laser Cutting Technology Revolutionize Metal Fabrication IndustryIntroduction (100 words):Metal fabrication is an essential process in various industries, ranging from automotive to aerospace. In recent years, laser cutting technology has emerged as a game-changer in the metal fabrication industry, providing high precision and efficiency. Various companies, including a prominent industry player offering laser cutting machines, have introduced innovative solutions to meet the growing demand. The metal tube laser cutting machine, developed by one such firm, has garnered attention for its ability to cut both sheet metal and tubes with utmost accuracy and speed. This new technology is set to revolutionize the metal fabrication industry.Section 1: Laser Cutting Machines - A Paradigm Shift in Metal Fabrication (200 words):Laser cutting machines have become commonplace in modern metal fabrication processes due to their unmatched precision, versatility, and efficiency. The advent of fiber metal laser cutters has significantly enhanced the capabilities of these machines. By utilizing a high-powered laser beam, these machines can cut through a wide range of sheet metals and tubes with exceptional precision and minimal material wastage.Bodor, a renowned company at the forefront of laser cutting technology, has introduced an array of cutting-edge machines catered for both sheet and tube cutting applications. The company's sheet/plate laser cutting machines are equipped with advanced software and high-powered lasers, enabling swift and precise cutting of various metal sheets. Simultaneously, their tube/pipes laser cutting machines leverage Bodor's expertise to cut intricate designs on cylindrical and tubular metal units with unparalleled accuracy.Section 2: The Innovative Metal Tube Laser Cutting Machine (300 words):One of Bodor's groundbreaking introductions is the metal tube laser cutting machine. This cutting-edge technology combines the capabilities of Bodor's sheet and tube cutting machines into a single, highly efficient unit. Traditionally, fabricators had to rely on multiple machines to perform these tasks. Still, the metal tube laser cutting machine seamlessly integrates both processes into a single workstation, saving both time and resources.The metal tube laser cutting machine leverages Bodor's patented technology, including advanced laser beam delivery systems, precise motion control mechanisms, and intelligent software. By employing an innovative rotary chuck design, this machine can effectively handle tubes of varying diameters, making it highly versatile for manufacturing industries.Moreover, Bodor's metal tube laser cutting machine supports a wide range of materials, including stainless steel, aluminum, copper, and brass. This versatility ensures that fabricators can produce high-quality components for a wide range of applications, such as automotive exhaust systems, architectural structures, and industrial piping.The machine's software, complemented by its intuitive user interface, allows fabricators to import complex designs seamlessly. The software then automatically generates the required cutting paths, optimizing material usage and minimizing production time. Additionally, the advanced motion control system ensures maximum accuracy, resulting in precise and intricate cuts.Section 3: Impact on the Metal Fabrication Industry (200 words):The introduction of Bodor's metal tube laser cutting machine marks a significant milestone in the metal fabrication industry. By combining sheet and tube cutting capabilities, fabricators can streamline their production processes, reducing costs and improving overall efficiency. The precision and versatility offered by these machines eliminate the need for costly secondary operations and hand finishing.Furthermore, the high-power laser and intelligent software-driven cutting paths have significantly reduced material wastage, maximizing resource utilization. This has a positive impact on the environment by promoting sustainable manufacturing practices.In conclusion, the advancements in laser cutting technology, particularly the metal tube laser cutting machine developed by Bodor, are revolutionizing the metal fabrication industry. With enhanced precision, efficiency, and material versatility, these machines allow fabricators to achieve intricate cuts on both sheet metal and tubes. As a result, the industry is witnessing improved productivity, reduced costs, and increased sustainability, making laser cutting machines indispensable tools for modern metal fabrication.

Top 10 Must-Have Cutting Accessories for Every DIY Enthusiast

Cutting Accessories Offers High-Quality Tools for Professional and DIY ProjectsCutting Accessories is a leading provider of cutting tools and equipment for professionals and do-it-yourself enthusiasts. With a wide range of products and accessories, the company has become a go-to destination for those in need of reliable and high-quality tools for various cutting applications. From blades and saws to drill bits and specialty tools, Cutting Accessories has everything needed to make precise and efficient cuts in a variety of materials.The company specializes in providing top-notch products from a variety of trusted brands, ensuring that customers have access to the best tools available on the market. Whether it's for construction, woodworking, metalworking, or any other cutting requirement, Cutting Accessories has the right tool for the job.One of the key factors that set Cutting Accessories apart from other retailers is its dedication to customer satisfaction. The company's team of experts is committed to helping customers find the perfect tool for their specific needs, offering valuable advice and guidance to ensure that every purchase meets or exceeds expectations. Additionally, Cutting Accessories provides a seamless shopping experience, with fast shipping and excellent customer service, making it easy for customers to get the tools they need when they need them.In addition to its extensive product selection and commitment to customer service, Cutting Accessories also offers competitive pricing, making high-quality cutting tools accessible to a wide range of customers. Whether you're a professional contractor in need of reliable equipment for your business or a hobbyist looking for the best tools for your projects, Cutting Accessories has the products and expertise to help you get the job done right.One of the standout products offered by Cutting Accessories is its line of precision blades. These blades are engineered to deliver exceptional performance and longevity, making them an excellent investment for professionals and hobbyists alike. With options for cutting wood, metal, plastic, and more, these blades are designed to provide clean and accurate cuts with minimal effort, making them an invaluable tool for any cutting project.In addition to blades, Cutting Accessories also offers a wide range of saws, including circular saws, jigsaws, reciprocating saws, and more. These saws are designed to handle a variety of cutting tasks with ease, providing the power and precision needed to tackle even the toughest jobs. Whether you're in need of a heavy-duty saw for professional use or a versatile tool for DIY projects, Cutting Accessories has the right saw for you.For those in need of drill bits and specialty cutting tools, Cutting Accessories also has an impressive selection of high-quality products. With options for drilling, shaping, and cutting a variety of materials, these tools are designed to deliver exceptional performance and durability, ensuring that customers can tackle any cutting task with confidence.Overall, Cutting Accessories is dedicated to providing top-notch cutting tools and equipment for professionals and DIY enthusiasts. With a commitment to customer satisfaction, a wide selection of high-quality products, and competitive pricing, the company has become a trusted source for cutting tools and accessories. Whether you're in need of blades, saws, drill bits, or specialty tools, Cutting Accessories has everything you need to make precise and efficient cuts in any material.

High-Quality Fiber Laser Available for Purchase

Fiber Laser For Sale – A Game-Changer in the Industrial Laser MarketFiber lasers are quickly becoming the preferred choice for industrial laser applications due to their high efficiency, precision, and reliability. The demand for fiber lasers has been steadily increasing in various industries such as automotive, aerospace, electronics, and medical devices. As a result, many companies are looking to invest in fiber lasers to enhance their manufacturing capabilities.One company that has been at the forefront of the fiber laser technology is {}. They have been a leading manufacturer of fiber laser systems for over a decade and have established a strong reputation for delivering high-quality and reliable products to their customers. With a wide range of fiber laser systems designed for various applications, they have become a trusted partner for many businesses looking to upgrade their laser technology.Recently, {company} has announced a new fiber laser for sale, which is expected to make a significant impact on the industrial laser market. The new fiber laser incorporates the latest advancements in laser technology, making it a game-changer for businesses looking to improve their manufacturing processes.One of the key features of the new fiber laser is its high power output, which allows for faster cutting and welding processes. This is particularly beneficial for industries that require high-speed and precision manufacturing, such as the automotive and aerospace sectors. The ability to process a wide range of materials, including metals, plastics, and ceramics, makes this fiber laser a versatile tool for various manufacturing applications.In addition to its high power output, the new fiber laser also boasts improved energy efficiency, reducing operating costs for businesses. This is a significant advantage for companies looking to minimize their environmental impact and lower their overall production expenses. With the rising demand for sustainable manufacturing practices, the energy-efficient design of this fiber laser is a timely solution for businesses seeking to reduce their carbon footprint.Moreover, the new fiber laser is equipped with advanced control systems, allowing for seamless integration into existing manufacturing processes. This makes it easier for businesses to adopt the new technology without disrupting their operations, thus ensuring a smooth transition to improved laser capabilities.{Company} takes pride in providing comprehensive customer support, including installation, training, and maintenance services for their fiber laser systems. This ensures that businesses can maximize the benefits of their investment and achieve optimal performance from their new fiber laser. With a dedicated team of technical experts, {company} is committed to assisting their customers throughout the entire lifecycle of their fiber laser systems.In response to the growing demand for fiber lasers, {company} has expanded its distribution network to reach businesses worldwide. With a global presence, they are well-positioned to cater to the needs of a diverse range of industries, offering customized solutions tailored to their specific requirements.The introduction of the new fiber laser for sale from {company} signifies a significant advancement in the field of industrial laser technology. With its cutting-edge features and robust performance, this fiber laser is poised to set new standards in precision manufacturing and streamline production processes for businesses across various sectors.As the industrial landscape continues to evolve, the demand for advanced laser technology is expected to rise. With {company} at the helm of fiber laser innovation, businesses can look forward to embracing the future of manufacturing with confidence and efficiency. The new fiber laser for sale is a testament to {company}'s commitment to delivering excellence and driving progress in the industrial laser market.

Tools and Accessories for Welding Machines and Upgrades

article about the benefits of investing in high-quality welding machines and accessories.Welding machines and accessories are at the core of any welding operation, and investing in high-quality equipment is essential for achieving precise, consistent, and high-quality welds. As the demand for welding services continues to increase in various industries, companies that prioritize the quality of their equipment can improve their productivity, efficiency, and profitability. This is where Arc-Zone.com, a leading welding accessories store, comes in, providing a wide range of welding machines and tools that meet the diverse needs of welders.Arc-Zone.com has become a trusted partner for welders of all skill levels, providing comprehensive solutions for welding tools and accessories both online and offline. The company has established a reputation for offering reliable and high-performance welding machines, from TIG and MIG welders to plasma cutting systems, along with all the necessary accessories to make welding processes more manageable. The elevated level of craftsmanship in each of these machines is what sets them apart from cheaper counterparts.The higher price of high-quality welding machines and accessories may seem prohibitive to some, but in reality, they offer numerous benefits that justify their value. For starters, investing in these machines reduces the risk of frequent repairs and replacements, which translates to cost savings in the long run. In addition, high-quality machines are designed to deliver high levels of efficiency and productivity, reducing production times and increasing output. This is particularly useful in commercial settings, where welding operations are time-bound.Another benefit of investing in high-quality welding machines and accessories is the improvement in the quality of welds. Precision is a hallmark feature of these machines, which ensures that welds are consistent, strong, and visually appealing. This can greatly enhance the overall quality of products that require welding, improving their durability and reliability. High-quality welding machines and accessories can also help reduce the likelihood of safety hazards in the workplace, as they are designed to operate safely, reducing risks such as electric shock, burns, and eye damage to the welder.Arc-Zone.com's product offerings meet the needs of both novice and professional welders. The company's wide range of welding machines includes reliable TIG welders, precise MIG welders, and efficient plasma cutters, each designed with the specific requirements of each process in mind. The machines come in different sizes and capabilities, allowing welders to choose a fitting machine that can deliver the desired results. The company also offers a selection of accessories to go with each machine, such as connectors, reels, and adapters, as well as gas purging equipment and remote amperage controls.The superiority of Arc-Zone.com's welding machines and accessories lies in the attention to detail and the use of high-quality components and materials. These machines are built to withstand the rigors of demanding welding environments, maintain their accuracy, and durability even after prolonged use. The company also employs continuous research and development in the manufacture of its products, ensuring that withstands future demands and applications in the industry.In conclusion, investing in high-quality welding machines and accessories such as those offered by Arc-Zone.com is necessary for any welding operation. The benefits of precision, efficiency, increased output, and safety, among others, justify the higher costs associated with these machines. With a wide range of machines and accessories designed to meet the needs of both novice and professional welders, Arc-Zone.com is a reliable provider of high-quality welding products. Welders using their products can be confident in achieving high-quality welds, increased productivity, and reduced repair costs.

High-Quality Servo Motors for CNC Machines: What You Need to Know

CNC Servo Technology Enhances Precision and Efficiency in ManufacturingIn today's highly competitive manufacturing industry, companies are constantly seeking ways to enhance the precision and efficiency of their production processes. One technology that has revolutionized the manufacturing industry is the CNC servo system. This advanced technology has significantly improved the accuracy and speed of machining operations, leading to higher-quality products and increased productivity.The CNC servo system, developed by (), is a cutting-edge technology that combines computer numerical control (CNC) with servo motor technology to control the movement of industrial machines with unparalleled precision. This system has been widely adopted by manufacturers across various industries, including automotive, aerospace, electronics, and medical devices, to streamline their production processes and achieve superior product quality.The servo motors used in the CNC servo system are known for their high torque, low inertia, and precise control capabilities. These characteristics make them ideal for controlling the movement of machine tools, such as lathes, mills, and routers, with extreme accuracy. The CNC servo system's ability to precisely control the speed, position, and torque of these machines has significantly improved the accuracy and repeatability of machining operations.Furthermore, the CNC servo system's advanced control algorithms and feedback mechanisms allow for real-time monitoring and adjustment of machine movements, ensuring consistent and precise machining results. This level of control and monitoring is essential for achieving tight tolerances and high surface finishes in the production of complex parts and components.In addition to improving precision, the CNC servo system has also enhanced the efficiency of manufacturing processes. The high-speed and precise movements enabled by the servo motors have reduced cycle times and increased throughput, ultimately leading to higher productivity and lower production costs. By utilizing the CNC servo system, manufacturers can now produce more parts in less time, making their operations more competitive in the global marketplace.Moreover, the CNC servo system's compatibility with various types of CNC machines and its seamless integration with existing manufacturing systems have made it a versatile and cost-effective solution for manufacturers looking to upgrade their production capabilities. Whether it's retrofitting an existing machine or implementing a new CNC system, the CNC servo technology offers a flexible and scalable solution for improving manufacturing performance.As a leading provider of CNC servo technology, () has been at the forefront of innovation in the manufacturing industry. With a rich history of developing cutting-edge motion control solutions, () has continuously pushed the boundaries of precision and efficiency in manufacturing. The company's commitment to research and development has resulted in the creation of advanced servo motor technology that is now widely used in CNC systems around the world.() has also been dedicated to providing comprehensive support and assistance to manufacturers looking to adopt CNC servo technology. From system design and integration to technical service and training, () has ensured that its customers can maximize the benefits of CNC servo systems in their production operations. This level of commitment has earned () a strong reputation as a trusted partner in the manufacturing industry.In conclusion, the CNC servo system has proven to be a transformative technology for the manufacturing industry, offering unparalleled precision and efficiency in machining operations. By combining the power of CNC with advanced servo motor technology, () has provided manufacturers with a competitive edge in delivering high-quality products while improving their productivity. As manufacturing processes continue to evolve, the role of CNC servo technology will undoubtedly be pivotal in driving the industry forward.