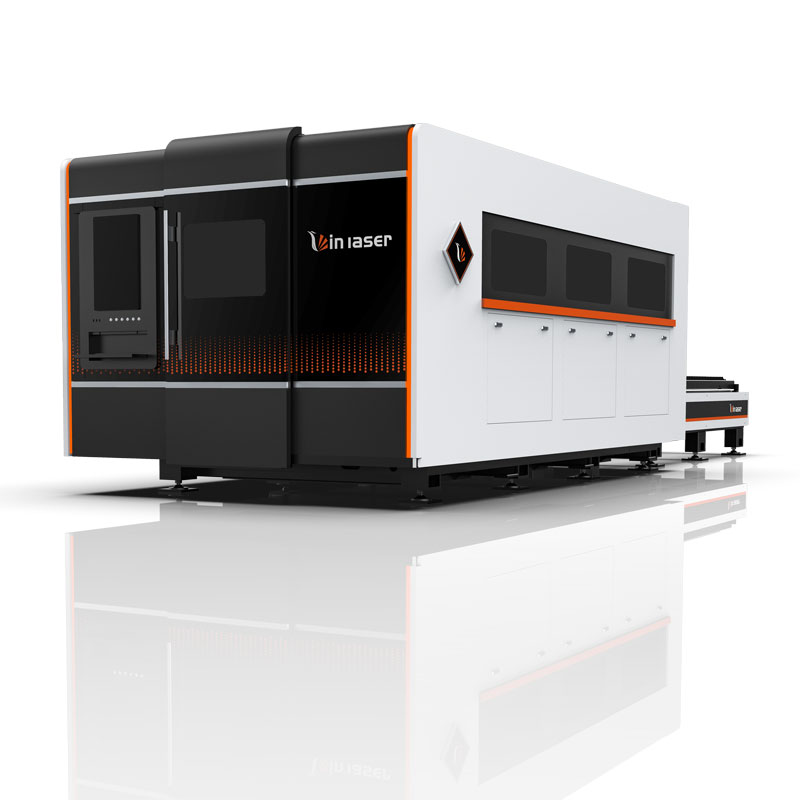

High-Quality Fiber Welder for Efficient Welding

By:Admin

In the world of industrial manufacturing, welding is an essential process for connecting various metal components. Traditionally, welding has been performed using techniques such as arc welding, MIG welding, and TIG welding. However, a new player has entered the field of industrial welding, offering a revolutionary solution that is set to change the game - Fiber Welder (brand name removed).

Fiber Welder is a cutting-edge welding technology that offers a wide range of benefits over traditional welding methods. This innovative technology uses fiber laser beams to melt and fuse metal components together, resulting in a stronger and more precise weld. In addition, Fiber Welder is capable of welding a wide variety of metals, including steel, aluminum, and titanium, making it a versatile solution for a range of industrial applications.

One of the key advantages of Fiber Welder is its ability to produce high-quality welds with minimal heat-affected zones. This means that the surrounding areas of the weld remain relatively unaffected by the welding process, reducing the risk of warping and distortion. This is particularly important for industries such as aerospace, automotive, and electronics, where precision and quality are paramount.

Furthermore, Fiber Welder offers significant productivity gains compared to traditional welding methods. Its high-speed welding capabilities allow for faster production cycles, resulting in increased throughput and reduced lead times. This is a game-changer for manufacturers looking to improve efficiency and meet tight production deadlines.

The company behind this groundbreaking technology, {company name}, is a leading provider of laser welding solutions for industrial applications. With a strong focus on research and development, {company name} has been at the forefront of advancing laser welding technology for over a decade. The company's team of engineers and technicians are dedicated to pushing the boundaries of what is possible in the field of industrial welding, and Fiber Welder is the culmination of their efforts.

In addition to its technical prowess, {company name} prides itself on its commitment to customer satisfaction. The company provides comprehensive support and training for its Fiber Welder systems, ensuring that customers can maximize the potential of this cutting-edge technology. This dedication to customer service has earned {company name} a loyal and satisfied customer base, further solidifying its position as a leader in the field of industrial welding.

The introduction of Fiber Welder comes at a time when the manufacturing industry is undergoing rapid transformation. With increasing demands for high-quality, precision-engineered components, manufacturers are seeking innovative solutions to meet these challenges. Fiber Welder is poised to address these needs head-on, offering a welding technology that is not only superior in quality but also more efficient and cost-effective.

As the global manufacturing industry continues to evolve, the demand for advanced welding solutions is expected to grow. With Fiber Welder, {company name} is well-positioned to capitalize on this trend and solidify its position as a key player in the industrial welding market. The company's dedication to innovation and commitment to customer satisfaction bode well for the continued success of Fiber Welder in the years to come.

Company News & Blog

Advanced Fiber Laser Training: Everything You Need to Know

Fiber Laser Training Provides Advanced Skills for Industrial ProfessionalsIn today's competitive industrial landscape, it is crucial for professionals to stay updated with the latest technological advancements. One such advancement is the use of fiber lasers in various industrial applications. Fiber lasers are an advanced type of laser technology that offers high precision and efficiency in cutting, welding, marking, and other material processing tasks.To meet the growing demand for skilled professionals in this field, [Company Name] is now offering comprehensive fiber laser training programs. These training programs are designed to equip industrial professionals with the necessary skills and knowledge to effectively operate and maintain fiber laser systems.[Company Name] has been a leading provider of industrial machinery and equipment for over 20 years. The company is known for its commitment to innovation and continuous improvement in the industrial sector. With its extensive experience and expertise in laser technology, [Company Name] is now leveraging its capabilities to offer high-quality training programs for industrial professionals.The fiber laser training programs offered by [Company Name] cover a wide range of topics, including the fundamentals of fiber laser technology, system operation and maintenance, safety protocols, troubleshooting, and advanced applications. The programs are designed to cater to professionals with varying levels of experience and expertise in the field, making them suitable for beginners as well as experienced operators.The training programs are conducted by a team of highly skilled and experienced instructors who have a deep understanding of fiber laser technology and its practical applications. The instructors utilize a combination of theoretical lectures, hands-on practical sessions, and real-world case studies to provide a well-rounded learning experience for the participants.One of the key advantages of the fiber laser training programs offered by [Company Name] is the hands-on experience that participants receive. The training sessions are conducted in state-of-the-art facilities equipped with the latest fiber laser systems, allowing participants to gain practical experience in operating and troubleshooting these advanced machines.Furthermore, [Company Name] provides customized training programs to cater to the specific needs of individual businesses and industries. This flexibility allows companies to ensure that their employees receive training that is tailored to their unique requirements and operational environment.Upon successful completion of the training programs, participants receive a certification from [Company Name] that serves as a testament to their proficiency in fiber laser technology. This certification is recognized by industry professionals and employers, providing participants with a competitive edge in the job market.The fiber laser training programs offered by [Company Name] have been well-received by industrial professionals from various sectors, including automotive, aerospace, electronics, and metal fabrication. Participants have praised the high-quality training curriculum, the expertise of the instructors, and the practical learning experience provided by [Company Name].In conclusion, the introduction of fiber laser training programs by [Company Name] is a testament to the company's commitment to providing advanced skills and knowledge to industrial professionals. These training programs are designed to address the growing demand for skilled fiber laser operators and technicians in the industrial sector. With its expertise and experience in the field, [Company Name] is well-positioned to make a significant contribution to the development of a highly skilled workforce capable of harnessing the full potential of fiber laser technology. As the industrial landscape continues to evolve, training programs like these will play a crucial role in shaping the future of manufacturing and material processing industries.

High-Quality Fiber Laser Cutting Services for Precision Metal Cutting

Fiber Laser Cutting Services Offers High-Quality, Precise Cutting SolutionsIn today's rapidly evolving manufacturing industry, the demand for high-quality, precise cutting solutions has never been greater. As a result, companies are constantly seeking ways to enhance their capabilities and stay ahead of the competition. One company that has been at the forefront of this trend is {}, a leading provider of fiber laser cutting services.With a strong focus on innovation and cutting-edge technology, {} has established itself as a trusted partner for businesses across a wide range of industries. The company's fiber laser cutting services are known for their superior precision, speed, and flexibility, making them an ideal choice for a variety of applications.One of the key advantages of fiber laser cutting is its ability to produce high-quality cuts with minimal heat-affected zones. This is achieved through the use of a high-powered laser beam, which is guided by advanced CNC controls to accurately and efficiently cut through a wide range of materials, including metal, plastic, and composites.In addition to its cutting precision, fiber laser cutting offers several other benefits, such as increased productivity, lower operating costs, and reduced lead times. This has made it a popular choice for companies looking to streamline their manufacturing processes and improve overall efficiency.{}'s state-of-the-art manufacturing facility is equipped with the latest fiber laser cutting technology, allowing the company to handle projects of virtually any size and complexity. With a team of skilled technicians and engineers, {} is able to work closely with clients to develop customized cutting solutions that meet their specific requirements.Furthermore, {} takes pride in its commitment to quality and customer satisfaction. The company adheres to strict quality control standards throughout the production process, ensuring that the finished products meet the highest industry standards. This attention to detail has earned {} a solid reputation for delivering exceptional results, time and time again.In addition to its cutting-edge technology and unwavering commitment to quality, {} is also dedicated to sustainability and environmental responsibility. The company has implemented several initiatives to minimize its carbon footprint and reduce waste, making it an environmentally conscious choice for businesses seeking to partner with a responsible supplier.As a testament to its success and innovation in the field of fiber laser cutting, {} has received numerous accolades and certifications, further solidifying its position as a leader in the industry. The company's track record of excellence and reliability has earned it the trust and confidence of clients from all over the world.Looking ahead, {} is poised to continue its growth and expansion, with a focus on further enhancing its capabilities and exploring new opportunities in the market. By staying at the forefront of technological advancements and remaining dedicated to its core values, {} is well-positioned to meet the evolving needs of its clients and maintain its leading role in the industry.In conclusion, fiber laser cutting services offered by {} are second to none in terms of precision, quality, and reliability. With a strong foundation built on innovation, expertise, and a customer-centric approach, {} is set to remain a driving force in the industry for years to come. Whether it's for a small-scale project or a large-scale production run, businesses can trust {} to deliver cutting-edge solutions that meet their unique requirements and exceed their expectations.

Efficient CO2 Laser Cutting Machine for Non-Metal Materials

, CO2 Laser Cutter, Laser Engraving Machine, Laser Cutting Technology, Laser Cutting Process.CO2 Laser Cutting Machine: A Revolution in Laser Cutting TechnologyThe use of laser technology has revolutionized the manufacturing industry in the last few decades. Laser cutting machines have brought precision, speed, and cost-effectiveness to the production process of various materials. Among the different types of laser cutting machines available, CO2 laser cutting machines have garnered a lot of attention due to their versatility, low cost, and efficiency.CO2 Laser Cutting Machines: The Best Choice for Small and Medium EnterprisesCO2 laser cutting machines are capable of processing nonmetal materials like wood, cloth, leather, and glass with precision and speed. These machines use a gas mixture of carbon dioxide, helium, and nitrogen to create a laser beam that cuts through the material. Due to their low cost and high efficiency, these machines have become the top choice for small and medium enterprises as well as individual customers.Advantages of CO2 Laser Cutting MachinesThe advantages of CO2 laser cutting machines are manifold. First and foremost, these machines are highly accurate and precise, ensuring a high-quality end product. Secondly, they have a faster cutting speed as compared to traditional cutting methods. This not only increases productivity but also reduces the overall production time. Thirdly, CO2 laser cutting machines are versatile and can be used to cut various materials of different thicknesses and shapes, making them ideal for customizations. Lastly, these machines can be easily integrated into the production line and require minimal maintenance.Applications of CO2 Laser Cutting MachinesCO2 laser cutting machines have a wide range of applications in various industries. In the textile industry, these machines are used to create intricate designs and patterns on fabrics. They are also used to cut the fabric pieces precisely and quickly. Similarly, in the leather industry, CO2 laser cutting machines are used to cut and engrave leather products, such as shoes, bags, and belts. CO2 laser cutting machines are also used in the woodworking industry to cut and engrave custom designs on wood products. In the advertising industry, CO2 laser cutting machines are used to create custom designs, logos, and signage on various materials.ConclusionIn conclusion, the CO2 laser cutting machine is a versatile and cost-effective tool that has revolutionized laser cutting technology. It offers many advantages over traditional cutting methods, including high accuracy, faster cutting speed, versatility, and minimal maintenance requirements. The wide range of applications of CO2 laser cutting machines in various industries makes them an essential tool for small and medium enterprises and individual customers. If you are looking for a reliable and efficient cutting tool, consider investing in a CO2 laser cutting machine.

Advanced 2D Flat Laser Cutting Services for High-Volume Production Projects

article about the latest advancements in laser cutting.Summit Steel & Manufacturing, Inc. has been known for delivering high-quality metal fabrications and machining solutions. Their latest advancement in laser cutting technology has allowed them to deliver excellent results for high-volume production projects. The 2D flat laser cutting process is a game-changer in the manufacturing industry, delivering smooth, clean edges, tight tolerances, and consistent results.With Summit Steel & Manufacturing, Inc.'s state-of-the-art laser cutting system, you can easily upload your prints or DXF files. The system's advanced technology allows for fast and efficient material utilization, resulting in enhanced productivity. The high precision of the laser cutting process ensures that every project is executed to perfection. This precision is what sets Summit Steel & Manufacturing, Inc. apart from its competitors.Laser cutting, in general, involves cutting a material using a high-powered laser beam. The laser beam is directed by a computer that controls its position, power, speed, and duration. This process is perfect for a wide range of materials, including metals, plastics, glass, and ceramics. This versatility has led to an increase in the use of laser cutting technology in various industries.One significant benefit of laser cutting technology is its high accuracy. The accuracy of laser cutting is unmatched compared to other cutting technologies. Laser cutting is also known for its speed, which is one of its significant advantages. Cutting a material using traditional methods can take a lot of time. Laser cutting technology speeds the process considerably, thus making it an ideal solution for high-volume production projects.Laser cutting technology is also environmentally friendly. With no toxic chemicals or gases involved in the process, laser cutting produces minimal waste. Additionally, the unit cost of laser cutting is lower compared to other traditional cutting methods, making it an economical option.Apart from the advantages mentioned earlier, laser cutting technology has advanced significantly over the years. The latest technology introduces new features that make the process even more efficient and precise. For example, some of the latest laser cutting technologies come with a fiber-optic laser cutting system, which can cut materials much faster than traditional laser cutting machines.Summit Steel & Manufacturing, Inc.'s laser cutting system also comes with an automatic nozzle changer. This feature makes it possible to shift from one cutting application to another with ease. The system also boasts an offline programming capability, enabling the operator to program the machine on a different computer while the machine is still in use.Laser cutting technology is very versatile, and its applications are endless. In the automotive industry, the technology can be used to cut metal parts, such as exhaust systems or brackets used in the engine. In the aerospace industry, laser cutting technology can be used to cut aircraft parts, such as cockpit and fuselage parts. Laser cutting technology is also used to manufacture electronic components, signage, and jewelry.In conclusion, Summit Steel & Manufacturing, Inc.'s latest advancement in laser cutting technology is a game-changer. The 2D flat laser cutting process delivers smooth, clean edges, tight tolerances, and consistent results, making it perfect for high-volume production projects. The precision, speed, and flexibility offered by laser cutting technology make it a versatile solution for a wide range of applications. As technology continues to evolve, laser cutting technology will become even more efficient, and its applications will continue to expand.

Laser Machinery Market Experiences Surge in Demand as Industries Adapt to Advanced Technologies

Title: Advancements in Laser Machinery Revolutionizing Industrial ManufacturingIntroduction:In the dynamic world of industrial manufacturing, laser machinery has emerged as a powerful tool that offers precision, speed, and flexibility. With its ability to cut, engrave, weld, and mark various materials, laser technology has revolutionized numerous industries including automotive, aerospace, electronics, and healthcare. One of the leading players in this market is a renowned company that specializes in cutting-edge laser equipment.Company Background:With several decades of industry expertise, the company has become a global leader in developing cutting-edge laser machinery. Renowned for its commitment to innovation, the company has consistently delivered high-quality products to its clientele worldwide. Its comprehensive range of laser machines cater to a diverse array of industrial applications, from small-scale enterprises to large-scale manufacturing plants.News Content:1. Introduction of Laser Machinery: The company's recently unveiled laser machinery series marks a significant milestone in the industry's progression. Designed to meet the evolving needs of manufacturers, these state-of-the-art machines offer enhanced capabilities and improved performance.2. Cutting-edge Laser Cutting Systems: The laser cutting systems from the company have gained wide acclaim for their ability to cut through a wide range of materials with unparalleled precision. Equipped with advanced laser sources and intelligent control systems, these machines deliver high-quality cuts with minimal material waste.3. Powerful Laser Engraving Solutions: The company's laser engraving solutions provide manufacturers with a versatile tool to add intricate designs, logos, and patterns to a variety of surfaces. These machines offer precise engraving across materials like wood, acrylic, metal, and glass, allowing businesses to customize their products effectively.4. Revolutionizing Manufacturing with Laser Welding: Laser welding machines have been pivotal in transforming the manufacturing landscape. Utilizing high-energy laser beams, these machines provide stronger welds, while minimizing deformation and heat-affected zones. The company's laser welding systems have been adopted by numerous industries, including automotive, electronics, and medical device manufacturing.5. Laser Marking for Traceability and Security: Laser marking technology has gained importance for its ability to create permanent markings on various materials, ensuring traceability and security. The company's laser marking systems offer quick, accurate, and legible markings, enabling businesses to comply with industry standards, improve product identification, and enhance brand recognition.6. Integration of Industry 4.0 Technologies: The company has integrated its laser machinery with Industry 4.0 technologies, enabling seamless connectivity, improved automation, and data-driven decision-making. Real-time monitoring, remote access, and advanced analytics optimize production processes, reduce downtime, and enhance overall operational efficiency.7. Commitment to Sustainability: As sustainability takes center stage in today's manufacturing landscape, the company remains committed to developing eco-friendly laser machinery. Their machines incorporate energy-saving features, reduce material waste, and adhere to stringent environmental standards.Conclusion:The company's pioneering contributions in laser machinery have propelled the industry forward, empowering manufacturers globally. By embracing innovation, continuously refining their products, and adapting to evolving market requirements, the company has established itself as a leader in the field. With its unwavering commitment to precision, speed, and sustainability, the company is set to shape the future of industrial manufacturing through its laser machinery solutions.

High-Quality CO2 Laser Lens and Mirror Cutting and Welding Machines Made in the USA

and Welding, American-made Laser Systems, Quality Laser Optics, Laser Technology Advancements.Advancements in Laser Technology: The Rise of Co2 Laser Cutting and WeldingIn recent years, the rise of Co2 laser cutting and welding has garnered the attention of manufacturing industries worldwide. This innovative technology has revolutionized the field by offering a more precise and efficient way to cut and weld a range of materials. One company that stands out when it comes to quality laser optics and American-made laser systems is American Photonics. In this blog post, we will explore the importance of quality laser optics and how American Photonics is setting the new standard for laser technology.Laser cutting and welding are vital processes in various industries, including automotive, aerospace, medical, and electronics. But, with the advancements of technology and innovation, traditional cutting and welding methods have evolved to a high level of precision and accuracy. Laser cutting and welding have taken over as the new standard for the manufacturing industry.Co2 Laser Technology AdvancementsCo2 laser technology is at the forefront of this revolution, providing accuracy and precision that surpasses traditional cutting methods. Co2 lasers are high-powered beams of light that can cut through steel up to 1.2 inches thick and other metals at a rapid pace. They can also weld materials from the thinnest sheet metal to the thickest plates and components. With Co2 laser technology, industries are enjoying benefits such as clean cuts, precise angles, and minimal material waste.Quality Laser Optics: the Importance of Choosing the Right ProviderHowever, the success of laser cutting and welding isn't solely dependent on the technology itself. The quality of the laser optics also plays a vital role. Laser optics can significantly impact the quality of the cut or weld through factors like the beam's focus, the speed of the cutting process, and more. Therefore, choosing the right laser optics provider enhances the technology's performance and efficiency and reduces downtime and repair costs.American Photonics: A New Standard for Quality American-Made Laser SystemsOne company that stands out in the laser optics industry is American Photonics. They offer 100% American-made laser systems and optics, with a focus on quality, performance, and durability. They utilize cutting-edge technology and employ a team of experts who design and manufacture their products.American Photonics offers a range of lens and mirror technologies, including reflective coated mirrors, copper mirrors, dielectric mirrors, and lens optics. Their high-quality products help ensure stable, efficient laser performance in the most demanding industrial applications. They've taken on the challenge of providing laser optics that withstand the demands of industrial use, and they continuously push the boundaries of laser technology to create the best performing solutions for their clients.ConclusionCo2 laser cutting and welding technology has brought about significant changes in the manufacturing industry. The consistent quality and precision of these methods are making traditional methods obsolete. However, the success of laser technology depends on quality laser optics, which improves the efficiency and performance of the technology. American Photonics, with its focus on quality optics and American-made laser systems, is leading the way in the laser optics industry. They continue to push the boundaries of laser technology to make manufacturing processes more efficient, accurate, and profitable.

Advanced CO2 Laser for Woodworking Applications: Automatic Focusing, Adjustable Table, Rotary Attachment, and Enhanced Durability

A Powerful Tool for Precision and Versatility: The CO2 Laser TableIn today's ever-evolving woodworking industry, having the right tools at your disposal is crucial to stay ahead of the competition. One such tool that has revolutionized the woodworking process is the CO2 laser table. This ingenious piece of equipment combines precision, versatility, and efficiency to enhance your woodworking capabilities like never before.One of the standout features of the CO2 laser table is its automatic focusing mechanism. This allows for quick and precise adjustments, ensuring that your laser beam is always focused on the desired area. In the past, manually focusing the laser beam could be time-consuming and often resulted in less than perfect outcomes. With the automatic focusing feature, you can now save time and achieve impeccable precision in your woodworking projects.Another remarkable aspect of the CO2 laser table is its automatically adjustable working table. Unlike traditional woodworking tables that are static and limited in their adaptability, the CO2 laser table can accommodate odd-shaped stock effortlessly. This means you can work on a wide variety of materials with different shapes and sizes, expanding your creative possibilities and making it easier to bring your vision to life.To further enhance its versatility, the CO2 laser table comes with a rotary attachment. This attachment allows you to work on cylindrical objects such as mugs, vases, and even wine glasses. With this feature, you can add intricate designs, logos, or even personalized engravings to give your work a unique touch.One of the most essential components of the CO2 laser table is the laser tube itself. (Brand name) utilizes top-of-the-line RECI laser tubes, renowned for their durability and power. These tubes ensure consistent and efficient performance, allowing for crisp and clean cuts or engravings on various materials. Whether you're working with wood, acrylic, leather, or even fabric, the CO2 laser table's laser tube will deliver impeccable results every time.The CO2 laser table is not only equipped with advanced laser technology but also designed for durability and stability. The HG series linear rails incorporated into the design provide high load capacity and rigidity. This ensures smooth and precise movements, even when working on large or heavy projects. No longer will you have to worry about inaccuracies or unsteady surfaces affecting the quality of your work.With a lifting height of 12 inches, the CO2 laser table caters to woodworking projects of varying sizes and requirements. Whether you're engraving intricate designs on a delicate piece or cutting through thick wood with utmost precision, this machine has got you covered. The generous lifting capacity paired with the automatic focusing and adjustable working table features make the CO2 laser table a highly versatile tool that can tackle a wide range of woodworking tasks.In conclusion, the CO2 laser table is a game-changer in the woodworking industry. With its automatic focusing mechanism, adjustable working table, and the ability to accommodate odd-shaped stock, it offers unparalleled precision and versatility. The rotary attachment allows for working on cylindrical objects, expanding your possibilities even further. With (brand name)'s choice of premium materials such as RECI laser tubes and the HG series linear rails, this machine delivers consistent and reliable performance. Whether you're a professional woodworker or an enthusiastic hobbyist, the CO2 laser table is the perfect companion to take your woodworking skills to the next level.Keywords: CO2 laser table, woodworking, automatic focusing, adjustable working table, precision, versatility, rotary attachment, power, durability, RECI laser tubes, HG series linear rails, lifting height.

Top 5 Laser Cutting Machines to Consider for Your Business

China Laser Cutting Machine, a leader in the manufacturing and development of laser cutting technology, is proud to announce the launch of their latest cutting-edge laser cutting machine. This new machine is set to revolutionize the industry with its precision, speed, and efficiency, setting a new standard for laser cutting technology.With over 20 years of experience in the industry, China Laser Cutting Machine has established itself as a premier provider of high-quality laser cutting machines. Their team of skilled engineers and technicians has worked tirelessly to design and develop a machine that meets the ever-evolving needs of their customers. The result is a state-of-the-art laser cutting machine that is unmatched in its capabilities.The new laser cutting machine boasts a number of impressive features that set it apart from the competition. One of the most notable features is its cutting precision, which is unparalleled in the industry. The machine is capable of cutting material with an accuracy of up to 0.1mm, ensuring that even the most intricate designs are executed with perfection.In addition to its precision, the new laser cutting machine also offers unprecedented speed and efficiency. With a cutting speed that is 30% faster than previous models, this machine is able to complete projects in record time without sacrificing accuracy or quality. This increased speed and efficiency not only saves time, but also reduces production costs, making it a valuable asset for any manufacturing operation.Furthermore, the machine incorporates the latest advancements in laser cutting technology to ensure optimal performance. Its advanced laser technology allows for the cutting of a wide range of materials, including metal, wood, acrylic, and more, making it a versatile tool for a variety of applications. Additionally, the machine is equipped with a user-friendly interface that allows for easy operation and programming, making it accessible to users of all skill levels.The launch of this new laser cutting machine represents a significant milestone for China Laser Cutting Machine, further solidifying their position as an industry leader. The company's commitment to innovation and quality is evident in the development of this machine, and it is sure to have a profound impact on the world of laser cutting technology.In addition to its cutting-edge technology, China Laser Cutting Machine also places a strong emphasis on customer satisfaction. They offer comprehensive training and support services to ensure that their customers are able to make the most of their investment. From installation and setup to ongoing maintenance and support, the company is dedicated to providing exceptional service every step of the way.As the global demand for precision cutting continues to grow, China Laser Cutting Machine is well-positioned to meet the needs of customers around the world. Their latest laser cutting machine is a testament to their ongoing commitment to excellence, and it is sure to set a new benchmark for the industry. With its unmatched precision, speed, and efficiency, this machine is poised to revolutionize the world of laser cutting technology.

Powerful Handheld Laser Welding Machine for 3.0mm Stainless Steel Applications

In recent times, the laser welding industry has undergone a significant change, with the proliferation of handheld laser welding machines. Handheld laser welding machine is an extremely efficient tool that offers significant advantages in terms of precision, cost-effectiveness, and versatility. Dapeng Laser Home, a leading company in China, has introduced a 1500 watt handheld laser welding machine.The new 1500 watt handheld laser welding machine is a breakthrough innovation that is capable of welding 3.0 mm stainless steel with ease. The product is designed to be user-friendly and efficient with a compact design that makes it portable and easy to carry around. The welding machine is equipped with advanced technology that reduces welding time, making it ideal for industrial and commercial applications.The machine's high power output and high-speed laser beam enable it to carry out various welding tasks, including spot welding, seam welding, and welding of thin plates, pipes, and tubes. Its excellent beam quality and precision welding make it an excellent choice for any welding project.Dapeng Laser Home, with over ten years of experience in the laser industry, has produced an amazing innovation that has won the hearts of welding professionals in China and worldwide. The company has been at the forefront of the laser industry, providing high-quality products that meet the growing demand for advanced welding solutions. The 1500 watt handheld laser welding machine is an example of the company's commitment to producing innovative laser products that meet the evolving needs of the industry.According to the company, the machine guarantees up to 95% welding rate, ensuring a high-quality weld that is consistent throughout the welding process. It also guarantees energy conservation, ensuring that users minimize their carbon footprint while also reducing energy costs. The machine is also equipped with an automatic alarm system that warns the operator of any abnormalities during the welding process, increasing safety while using the machine.Aside from the machine's high precision welding ability, it also boasts low maintenance costs and high durability. With the machine, users can expect reduced downtime, increased efficiency, and enhanced productivity. The machine is easy to operate, not requiring extensive training, which reduces frustration and gets you up and running in no time.Dapeng Laser Home has positioned itself at the forefront of the laser industry with the introduction of this 1500 watt handheld laser welding machine. The machine's high power output, excellent beam quality, precision, and user-friendly design have made it a favorite among welding professionals worldwide. The company's commitment to producing high-quality products has won it many clients in China and beyond.In conclusion, the 1500 watt handheld laser welding machine is an excellent choice for anyone seeking a versatile, cost-effective, and precise welding solution. With its high speed, precision welding, reduced downtime, and low maintenance cost, the machine is a valuable tool in the welding industry. Dapeng Laser Home has produced an innovation that is making a significant impact in the industry, and with its commitment to continual improvement, the company's future looks bright.

Top Co2 Laser Machines for Sale: Shop Now and Save

Buy Co2 Laser System for Improved Precision and EfficiencyThe demand for advanced laser technology continues to soar as businesses seek improved precision and efficiency in their operations. In response to this growing need, [Company Name] is pleased to announce the acquisition of a state-of-the-art Co2 laser system. This new addition to our cutting-edge equipment arsenal will enable us to deliver superior quality products and services to our esteemed clients.[Company Name] is a leading provider of laser cutting and engraving solutions, serving a diverse range of industries including automotive, aerospace, electronics, and medical. With a strong commitment to innovation and customer satisfaction, we constantly strive to invest in the latest technologies to stay at the forefront of the industry. The acquisition of the Co2 laser system is a testament to our dedication to delivering exceptional results to our clients.The Co2 laser system is equipped with advanced features that enable high-precision cutting and engraving on a wide variety of materials including acrylic, wood, glass, and metal. This technology offers exceptional beam quality, allowing for intricate and detailed designs with minimal heat-affected zones. With its fast processing speed and high accuracy, the Co2 laser system is ideally suited for applications that require complex geometries and fine details.One of the key advantages of the Co2 laser system is its versatility. Whether it's cutting intricate patterns on thin materials or engraving precise markings on thick substrates, this technology offers unparalleled flexibility. This means that [Company Name] can cater to a wide range of customer requirements, providing solutions that are tailored to their specific needs.In addition to its cutting and engraving capabilities, the Co2 laser system also offers enhanced efficiency and cost-effectiveness. The technology is capable of delivering high production volumes with minimal waste, making it an ideal choice for mass production applications. This improved efficiency not only benefits [Company Name] but also translates to cost savings for our clients, as we are able to offer competitive pricing without compromising on quality.Furthermore, the Co2 laser system is equipped with advanced automation features that streamline the production process. This allows for quick setup times, reduced manual labor, and improved overall productivity. As a result, [Company Name] is able to meet tight deadlines and deliver orders in a timely manner, ensuring customer satisfaction and loyalty.The acquisition of the Co2 laser system underscores [Company Name]'s ongoing commitment to investing in cutting-edge technology to better serve our clients. We recognize the ever-evolving needs of the market and are dedicated to staying ahead of the curve by embracing advancements that elevate our capabilities and services. With the addition of this advanced laser system, we are well-positioned to deliver exceptional results and exceed the expectations of our customers.At [Company Name], we take pride in our ability to deliver high-quality, precision-engineered products and services. With the Co2 laser system, we are confident that we will further enhance our position as a leader in the industry and continue to provide innovative solutions that drive the success of our clients. We look forward to leveraging the capabilities of this cutting-edge technology to bring value to our customers and foster long-lasting partnerships.