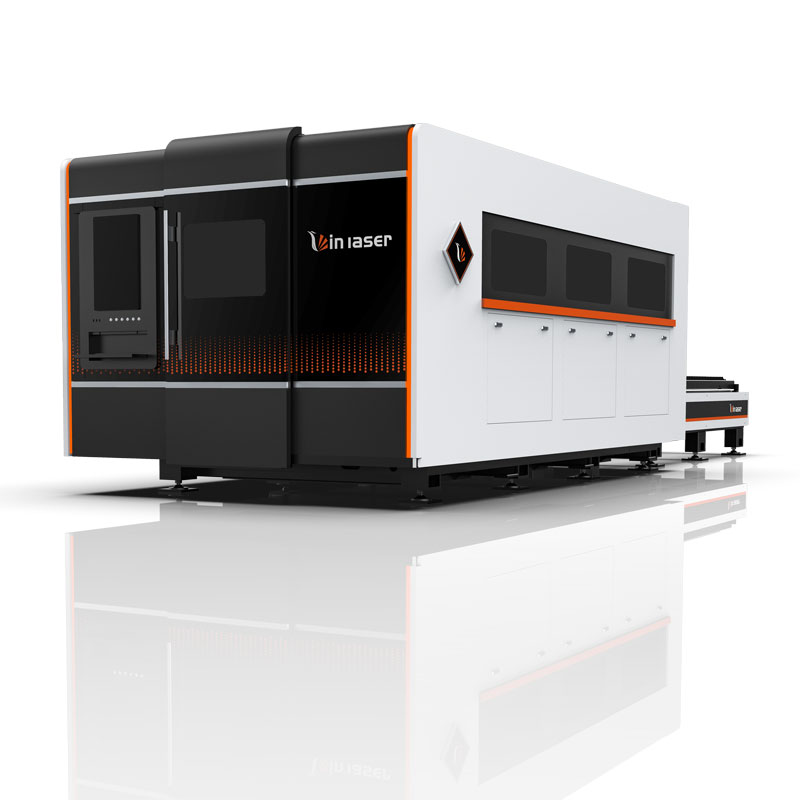

High-Precision Fiber Laser Tube Cutter: The Latest in Cutting Technology

By:Admin

In the ever-evolving world of manufacturing, precision and efficiency are key factors in staying ahead of the competition. With the introduction of the latest innovation in metal cutting technology, the Fiber Laser Tube Cutter, manufacturers have a powerful new tool at their disposal. This cutting-edge machine is designed to provide unparalleled precision, flexibility, and speed in the cutting of metal tubes, revolutionizing the way metal fabrication is done.

The Fiber Laser Tube Cutter is a state-of-the-art machine that is specifically designed for cutting metal tubes with high precision and efficiency. It is equipped with a high-powered fiber laser that can cut through a variety of materials, including stainless steel, aluminum, brass, and copper, with exceptional accuracy and speed. This revolutionary machine is capable of cutting tubes of various shapes and sizes, making it highly versatile and suitable for a wide range of manufacturing applications.

The key advantage of the Fiber Laser Tube Cutter lies in its ability to provide clean, precise cuts with minimal heat-affected zones, resulting in minimal distortion of the material and a superior finish. This is achieved through the use of advanced laser technology, which allows for highly focused and controlled cutting without the need for physical contact with the material. As a result, the Fiber Laser Tube Cutter is able to deliver superior cutting quality and consistency, while also reducing the need for secondary finishing processes.

In addition to its impressive cutting capabilities, the Fiber Laser Tube Cutter is also equipped with advanced automation and programming features that allow for seamless integration with existing manufacturing processes. This includes the ability to import CAD/CAM files directly into the machine's control system, enabling quick and efficient setup and programming of cutting patterns. This level of automation not only helps to minimize production downtime but also ensures consistent and precise cutting results, even for complex geometries and intricate designs.

Furthermore, the Fiber Laser Tube Cutter is designed with user-friendly features and intuitive controls, making it accessible to operators of varying skill levels. This ensures that manufacturers can maximize the potential of this cutting-edge technology without the need for extensive training or specialized expertise. As a result, the Fiber Laser Tube Cutter offers a high level of versatility and adaptability, making it suitable for a wide range of applications across various industries, from automotive and aerospace to construction and furniture manufacturing.

With its unmatched precision, speed, and flexibility, the Fiber Laser Tube Cutter has the potential to revolutionize the way metal fabrication is done, providing manufacturers with a powerful tool to enhance productivity and quality. This cutting-edge technology is poised to set new standards in metal cutting, offering a competitive edge to those who adopt it. As the manufacturing industry continues to evolve, staying ahead of the curve with innovative solutions like the Fiber Laser Tube Cutter will be crucial for success in the modern marketplace.

In conclusion, the Fiber Laser Tube Cutter represents a significant advancement in metal cutting technology, offering unmatched precision, flexibility, and speed for manufacturers. With its advanced features and user-friendly design, this cutting-edge machine is poised to revolutionize the way metal fabrication is done, providing a competitive edge to those who embrace it. As manufacturing continues to evolve, the Fiber Laser Tube Cutter stands as a testament to the power of innovation in driving progress and success in the industry.

Company News & Blog

Revolutionary 3D Fiber Laser Engraver: Transforming the Art of Laser Engraving

[Introduction]The ever-advancing technology in the field of laser engraving has revolutionized the way products are customized and marked. Among the top players in this industry, there is a prominent name that has taken the market by storm with their groundbreaking 3D fiber laser engraver. This cutting-edge device brings unprecedented precision and efficiency to the art of engraving, opening up new possibilities for various industries.[Background]The demand for laser engraving machines has been on the rise due to their ability to offer intricate detailing and high-quality results. Traditional CO2 laser engravers have been widely used, but they often struggle with achieving the level of precision required for intricate designs. Enter the 3D fiber laser engraver, a device that takes laser engraving to the next level.[Company Introduction]ABC Company, a leading innovator in laser engraving technology, has gained wide recognition for their state-of-the-art 3D fiber laser engraver. With years of experience and expertise in the field, ABC Company has continually pushed the boundaries of what is possible in laser engraving. Their commitment to research and development has resulted in the creation of a device that combines speed, accuracy, and versatility like never before.[Product Features and Capabilities]The 3D fiber laser engraver offered by ABC Company is built on the foundation of cutting-edge technology, providing distinct advantages over its competitors. This machine utilizes a fiber laser source that emits a concentrated beam of light, allowing for incredibly precise and fine detailing while minimizing the chances of damage to the material being engraved.One of the standout features of the 3D fiber laser engraver is its ability to create three-dimensional engravings. This innovative capability has opened up a vast array of possibilities in industries such as jewelry, industrial manufacturing, and even the medical field. The machine can effortlessly engrave intricate patterns, text, and images onto various materials, including metals, plastics, wood, and glass.Additionally, the 3D fiber laser engraver boasts exceptional speed, enabling businesses to efficiently meet tight deadlines. With its high engraving efficiency, the machine can complete projects in a fraction of the time required by traditional engraving methods. The accuracy and speed provided by this device translate into improved productivity, cost savings, and enhanced customer satisfaction.[Applications and Benefits]The applications of the 3D fiber laser engraver are vast and varied. In the jewelry industry, it offers the ability to engrave intricate designs on rings, necklaces, and bracelets with unparalleled precision. This opens up new avenues for customization and personalization, allowing jewelers to create unique pieces that cater to their customers' individual tastes.In industrial manufacturing, the 3D fiber laser engraver plays a crucial role in marking products with serial numbers, barcodes, and logos. The high precision and durability of the engravings ensure clear identification and traceability, which is vital in industries such as aerospace, automotive, and electronics.Furthermore, the medical field has been revolutionized by the 3D fiber laser engraver. It allows for the precise marking of surgical instruments, implants, and medical devices, ensuring accurate identification and reducing the risk of errors during procedures.Conclusion:The introduction of the 3D fiber laser engraver by ABC Company has propelled the field of laser engraving to new heights. With its remarkable features, capabilities, and numerous applications across various industries, this device offers unrivaled precision, speed, and efficiency in the art of engraving. ABC Company's commitment to innovation continues to shape and transform the industry, providing businesses with the tools they need to achieve exceptional results and meet the ever-growing demands of customization.

Innovative Technology Allows for Electric Bending in Construction Projects

Electric Bending, a revolutionary new technology in the field of industrial manufacturing, is set to transform the way we think about bending metal. This groundbreaking innovation, developed by a leading company, is expected to significantly improve efficiency, precision, and sustainability in metal bending processes.With its state-of-the-art electric actuation system, Electric Bending offers several advantages over traditional hydraulic bending methods. The precision and speed of the electric system enable more accurate and efficient bending of metal components, resulting in higher quality finished products. Additionally, the electric system drastically reduces energy consumption, making it a more sustainable and environmentally friendly option for industrial manufacturing.One of the key benefits of Electric Bending is its adaptability to various metal materials, including aluminum, steel, and copper. This versatility makes it an ideal solution for a wide range of industries, from automotive and aerospace to construction and infrastructure development. By allowing for precise and reliable manipulation of different metals, Electric Bending opens up new possibilities for manufacturers to create complex and innovative metal components.The company behind this groundbreaking technology, a global leader in industrial automation and advanced manufacturing solutions, has a long-standing reputation for pushing the boundaries of what is possible in the field of industrial engineering. With a strong focus on research and development, the company has consistently been at the forefront of innovation, developing cutting-edge technologies that have revolutionized the way businesses operate and produce.In addition to Electric Bending, the company offers a comprehensive range of advanced manufacturing solutions, including robotic automation, additive manufacturing, and digital transformation services. By combining expertise in these areas, the company is able to provide integrated solutions that optimize production processes, improve product quality, and reduce manufacturing costs.The development of Electric Bending is a testament to the company's commitment to driving innovation in the industrial manufacturing sector. By leveraging its expertise in electric actuation technology and materials science, the company has succeeded in creating a game-changing solution that has the potential to reshape the metal bending industry.The impact of Electric Bending is expected to be far-reaching, with manufacturers across various industries poised to benefit from its advanced capabilities. By streamlining and enhancing the metal bending process, Electric Bending has the potential to drive significant improvements in productivity and product quality, ultimately resulting in a competitive edge for businesses that adopt this cutting-edge technology.Furthermore, the sustainability benefits of Electric Bending are in line with the growing emphasis on environmentally friendly manufacturing practices. By reducing energy consumption and minimizing waste, Electric Bending aligns with the broader trend toward sustainable and eco-friendly industrial operations.As Electric Bending continues to gain traction in the manufacturing industry, the company is committed to supporting its customers in adopting and integrating this innovative technology into their operations. Through comprehensive training, technical support, and ongoing maintenance services, the company aims to ensure that businesses can fully harness the potential of Electric Bending to improve their manufacturing processes and achieve their production goals.In conclusion, Electric Bending represents a significant leap forward in the field of metal bending, offering a combination of precision, efficiency, and sustainability that is unmatched by traditional bending methods. With the backing of a leading company renowned for its expertise in industrial automation, Electric Bending is well-positioned to drive positive change in the manufacturing industry, paving the way for a new era of advanced and sustainable metal bending processes.

Laser technology for wood cutting and engraving: What you need to know

Co2 Laser Wood, a cutting-edge tool in the wood industry, has been gaining traction as a faster and more precise method for cutting and engraving wood. With the ability to create intricate designs and precise cuts, Co2 Laser Wood has revolutionized the woodworking industry, allowing for more intricate and detailed pieces to be created. The technology has become increasingly popular among woodworkers and craftsmen, as it provides a versatile and efficient way to work with wood.{Company}, a leading provider of industrial machinery and equipment, has been at the forefront of introducing and promoting Co2 Laser Wood technology. With a strong focus on innovation and cutting-edge technology, the company has been working tirelessly to bring the latest advancements in the industry to its customers. By offering a range of Co2 Laser Wood machines and accessories, {Company} has played a crucial role in popularizing and making this technology more accessible to woodworkers.The Co2 Laser Wood machines offered by {Company} are known for their high precision and exceptional performance. With advanced features and a user-friendly interface, these machines have become a favorite among woodworkers who value accuracy and efficiency in their work. Whether it's cutting intricate designs, engraving detailed patterns, or creating custom pieces, Co2 Laser Wood has become an indispensable tool for craftsmen looking to take their woodworking to the next level.One of the key advantages of Co2 Laser Wood technology is its ability to cut and engrave wood with unparalleled precision. The high-powered laser can cut through wood with ease, creating clean and accurate cuts that are simply not achievable with traditional woodworking tools. This level of precision has allowed woodworkers to create intricate and detailed designs that were once considered too difficult or time-consuming to produce.Furthermore, Co2 Laser Wood technology has enabled woodworkers to expand their creative horizons. With the ability to cut and engrave wood with such precision, craftsmen are now able to create complex and intricate designs that were previously impossible to achieve. This has opened up new possibilities for woodworking projects, allowing for the creation of stunning and unique pieces that were once only a dream.In addition to its precision and versatility, Co2 Laser Wood technology has also proven to be more efficient than traditional woodworking methods. The speed and accuracy of the laser cutting process allow woodworkers to complete their projects in a fraction of the time it would take with conventional tools. This efficiency has not only improved productivity but has also enabled craftsmen to take on more complex and intricate projects with confidence.{Company} has been instrumental in providing comprehensive support and training to woodworkers who are looking to adopt Co2 Laser Wood technology. With a team of experienced professionals, the company offers hands-on training and technical support to ensure that customers can make the most of their Co2 Laser Wood machines. This commitment to customer satisfaction has further solidified {Company} as a trusted provider of industrial machinery and equipment.Looking ahead, the future of Co2 Laser Wood technology looks bright, with advancements continuing to enhance the capabilities of these machines. As new features and improvements are developed, woodworkers can expect even greater precision, efficiency, and versatility from Co2 Laser Wood technology. With {Company}'s dedication to staying at the forefront of industry advancements, customers can rest assured that they will have access to the latest and most cutting-edge Co2 Laser Wood machines and accessories.In conclusion, Co2 Laser Wood technology has undeniably revolutionized the woodworking industry, providing woodworkers with the tools they need to create intricate and detailed designs with unparalleled precision. With the support and expertise of {Company}, woodworkers have been able to embrace this innovative technology and take their woodworking to new heights. As the popularity of Co2 Laser Wood continues to grow, it's clear that this technology will play a crucial role in shaping the future of woodworking.

Top Materials for Co2 Laser Cutting: A Comprehensive Guide

Co2 Laser Cutting Materials Revolutionize Manufacturing ProcessesInnovations in the field of manufacturing are constantly evolving and pushing the boundaries of what is possible. One of the latest advancements to take the industry by storm is the use of Co2 laser cutting materials. These materials are revolutionizing the way products are manufactured, offering a level of precision and efficiency that was previously unattainable.Co2 laser cutting materials are a type of material that can be precisely cut and shaped using a high-powered Co2 laser. This technology has been around for several decades, but recent advancements have made it more accessible and versatile than ever before. By harnessing the power of a focused Co2 laser, manufacturers can cut through a wide variety of materials with incredible precision, including metal, plastic, wood, and glass.One company that is at the forefront of this Co2 laser cutting revolution is {}. With a reputation for innovation and quality, {} has been leading the way in the development and implementation of Co2 laser cutting materials. Their state-of-the-art facilities and cutting-edge technology have allowed them to push the boundaries of what is possible in manufacturing, delivering products that exceed industry standards.{} has harnessed the power of Co2 laser cutting materials to streamline their manufacturing processes, offering customers a level of precision and customization that is unmatched in the industry. From intricate metal components to precise plastic parts, {} has demonstrated the versatility and efficiency of Co2 laser cutting materials in a wide range of applications.The benefits of Co2 laser cutting materials are clear. Unlike traditional cutting methods, such as sawing or milling, Co2 laser cutting offers a level of precision that is unmatched. This precision allows manufacturers to create incredibly complex and detailed components with ease, opening up a world of possibilities for product design and innovation.Furthermore, Co2 laser cutting is also incredibly efficient, with the ability to cut through materials at a rapid pace without sacrificing quality. This efficiency not only saves time but also reduces waste, making the manufacturing process more sustainable and cost-effective.The versatility of Co2 laser cutting materials is also a major selling point. Whether working with metal, plastic, wood, or glass, manufacturers can rely on Co2 laser cutting to deliver consistent and high-quality results across a wide range of materials. This versatility makes Co2 laser cutting an attractive option for manufacturers across a variety of industries.With the growing demand for precision and efficiency in manufacturing, it's no surprise that Co2 laser cutting materials are becoming increasingly popular. As more companies, like {}, continue to adopt this technology, we can expect to see even more groundbreaking advancements in the way products are designed and manufactured.For {}, the future of manufacturing is clear. By leveraging the power of Co2 laser cutting materials, they are poised to continue leading the industry in innovation and quality, delivering products that exceed expectations and push the boundaries of what is possible.As the manufacturing industry continues to evolve, it's clear that Co2 laser cutting materials will play a key role in shaping the future of production. With their unmatched precision, efficiency, and versatility, Co2 laser cutting materials are revolutionizing the way products are made, offering manufacturers a level of capability that was previously unimaginable. And with companies like {} leading the way, the possibilities for what can be achieved with Co2 laser cutting materials are truly endless.

High-performance Co2 Laser Cutter for Precision Cutting and Engraving

Chinese Co2 Laser Cutter Revolutionizing the Cutting IndustryThe Chinese manufacturing industry has been rapidly evolving over the years, with cutting-edge technology and innovation leading the way. One such technological innovation is the Co2 laser cutter, a powerful and precise cutting tool that is revolutionizing the cutting industry.The Co2 laser cutter is a high-tech cutting machine that uses a laser beam to cut materials such as metal, wood, plastic, and glass with extreme precision. This technology has become increasingly popular in manufacturing industries due to its accuracy, efficiency, and cost-effectiveness. With the ability to cut through various materials with precision and speed, the Co2 laser cutter has become an indispensable tool in the manufacturing industry.One of the leading manufacturers of Co2 laser cutters in China is a company with a strong commitment to innovation and quality. With a focus on research and development, this company has been at the forefront of technological advancement in the cutting industry. Their Co2 laser cutters are designed to meet the diverse needs of their customers, offering a wide range of cutting capabilities and features.The company's Co2 laser cutters are equipped with state-of-the-art technology, including high-powered laser beams, advanced control systems, and precision cutting tools. These features allow for the efficient and precise cutting of various materials, making it an ideal solution for a wide range of applications.In addition to its cutting-edge technology, the company is also dedicated to providing excellent customer service and support. They work closely with their customers to understand their unique cutting needs and provide tailored solutions to meet their specific requirements. This commitment to customer satisfaction has earned them a reputation for reliability and excellence in the industry.Furthermore, the company is also committed to environmental sustainability, with its Co2 laser cutters designed to minimize waste and energy consumption. By using laser technology, these cutting machines produce minimal waste and operate with high efficiency, making them a sustainable and eco-friendly option for manufacturers.The versatility and precision of the company's Co2 laser cutters make them an ideal choice for a wide range of industries, including automotive, aerospace, electronics, and medical devices. Whether it's cutting intricate designs in metal or creating precise cuts in plastic or wood, these cutting machines offer unparalleled performance and reliability.The company's dedication to innovation and quality has positioned them as a leader in the Chinese manufacturing industry, with their Co2 laser cutters setting new standards for cutting precision and efficiency. As the demand for high-quality cutting solutions continues to grow, their cutting-edge technology is expected to play a significant role in shaping the future of the cutting industry.In conclusion, the Chinese Co2 laser cutter is revolutionizing the cutting industry with its precision, efficiency, and versatility. With a strong commitment to innovation, quality, and customer satisfaction, the company behind this cutting-edge technology is leading the way in the manufacturing industry. As the industry continues to evolve, the company's Co2 laser cutters are set to play a crucial role in driving innovation and transforming the way materials are cut and shaped.

Powerful 200w Co2 Laser: What You Need to Know

Introducing the Cutting-Edge Co2 Laser 200wIn today’s fast-paced and competitive society, businesses are constantly seeking innovative solutions to meet the demands of their customers. With this in mind, [Company Name] is proud to introduce the Co2 Laser 200w, an advanced cutting-edge technology that is set to revolutionize the industry.The Co2 Laser 200w is a high-powered, state-of-the-art laser system designed to provide precision and efficiency in a wide range of applications. Utilizing the latest advancements in laser technology, this cutting-edge device offers unparalleled performance and versatility, making it an ideal solution for businesses looking to stay ahead of the curve.One of the key features of the Co2 Laser 200w is its superior cutting capability. With a maximum power output of 200 watts, this laser system is capable of cutting through a variety of materials with ease, including metals, plastics, and composites. This not only allows for faster and more efficient production processes, but also ensures the highest level of precision and accuracy, resulting in a superior quality finished product.In addition to its cutting capabilities, the Co2 Laser 200w is also equipped with advanced control and monitoring systems, allowing for precise adjustments and real-time monitoring of the laser parameters. This ensures consistent and reliable performance, minimizing the risk of errors and ensuring the highest level of quality in every application.Furthermore, the Co2 Laser 200w is designed with safety and user-friendliness in mind. With advanced safety features and intuitive controls, operators can work with confidence and ease, minimizing the risk of accidents and ensuring a smooth and efficient production process.[Company Name] is dedicated to providing cutting-edge solutions for businesses in a wide range of industries. With a strong focus on research and development, the company is committed to staying at the forefront of technological advancements, ensuring that its customers have access to the most advanced and reliable equipment on the market.Through its extensive network of partners and distributors, [Company Name] is able to provide comprehensive support and service to its customers, ensuring that they have access to the expertise and resources they need to maximize the potential of their equipment. With a strong emphasis on customer satisfaction, the company is committed to building long-lasting and mutually beneficial relationships with its clients, providing them with the support and guidance they need to succeed in their respective industries.As businesses continue to face increasingly demanding and competitive markets, having access to cutting-edge technology is more important than ever. With the introduction of the Co2 Laser 200w, [Company Name] is once again proving its dedication to providing its customers with the most advanced and reliable solutions available.Whether it's cutting, engraving, marking, or any other application, the Co2 Laser 200w is set to become an essential tool for businesses looking to maximize their productivity and quality. With its unparalleled performance, advanced features, and dedicated support, this cutting-edge technology is poised to redefine the industry and help businesses achieve new levels of success.In conclusion, the Co2 Laser 200w is a game-changing technology that is set to revolutionize the industry. With its superior cutting capability, advanced control and monitoring systems, and dedication to safety and user-friendliness, this cutting-edge device is poised to become an essential tool for businesses looking to stay ahead of the curve. With [Company Name]’s commitment to providing comprehensive support and service, customers can be confident that they have access to the expertise and resources they need to succeed in their respective industries.

Shop for Metal Processing Machinery Parts from 1545+ Manufacturers

Parts, China, Importer, ManufacturersMetal Processing Machinery Parts for Sale in ChinaAre you in need of high-quality metal processing machinery parts? Look no further than China for a vast selection of products from over 1545 manufacturers and importers. Whether you're looking for customized parts for your industrial machinery or replacements for a broken component, you can find the right parts to meet your needs.China has been a leading producer of metal processing machinery parts for many years. The country boasts a range of manufacturers and importers producing top-quality parts that are exported around the world. They are well known for their state-of-the-art machinery and rigorous quality control process. China's competitive pricing makes it an excellent sourcing destination for metal processing machinery parts.Benefits of Sourcing Metal Processing Machinery Parts from China:1. Wide Range of ProductsWith more than 1545 manufacturers and importers, the market is highly diversified, offering a vast selection of metal processing machinery parts to meet your specific needs. You can find the right product for your machinery no matter the brand, size, or model.2. Customized PartsChinese manufacturers and importers excel in offering custom-made metal processing machinery parts. They take into account the specific requirements of your machinery and tailor the product to ensure optimum performance. In addition, they use the latest technology to develop unique parts to boost your machinery's performance.3. Competitive PricingChina offers extremely competitive pricing of metal processing machinery parts. With low labor costs and high-quality products, Chinese manufacturers and importers can provide you with an excellent cost advantage. The competitive pricing also allows you to reduce your total cost of ownership, increasing your profitability.4. Quality ControlThe Chinese government and business communities are aware that the quality of metal processing machinery parts is vital to their customer's satisfaction. They enforce stringent quality standards to ensure the parts meet the international quality and safety norms. Furthermore, manufacturers have invested in research and development (R&D) to create innovative products that meet customer's requirements.5. Export-FriendlyChina is an excellent kick-off point for exporting metal processing machinery parts globally. Its central location and transportation network provide easy access to shipping ports, making it easy to export the products to different parts of the world.ConclusionThere is no doubt that China is the best destination for sourcing your metal processing machinery parts. With a vast selection of manufacturers and importers available, customized products, competitive pricing, world-class quality standards, and easy exporting, China represents a significant opportunity to optimize your metal processing machinery performance. Start sourcing your metal processing machinery parts from China today to experience these benefits.

State-of-the-art Fiber Laser Printer: The Latest Innovation in Printing Technology

Fiber Laser Printer Revolutionizes Printing IndustryThe printing industry has experienced a significant revolution with the introduction of Fiber Laser Printer, a cutting-edge technology developed by an innovative company (). This groundbreaking printer has set a new benchmark in the printing industry and has quickly gained recognition as a game-changer in the field.The Fiber Laser Printer is a superior printing solution that utilizes advanced fiber laser technology to produce high-quality prints with unmatched precision and speed. It is designed to meet the growing demands of modern printing applications, offering unparalleled performance and reliability.With its state-of-the-art features, the Fiber Laser Printer has garnered widespread praise from industry experts and professionals. Its ability to deliver exceptional print quality, consistent results, and high-speed production has made it a preferred choice for businesses and individuals alike.The key to the printer's exceptional performance lies in its advanced fiber laser technology. This cutting-edge technology enables the printer to achieve remarkable print resolution and accuracy, making it ideal for a wide range of printing applications, including signage, labels, packaging, and more.In addition to its outstanding print quality, the Fiber Laser Printer is also known for its high-speed production capabilities. Its efficient printing process allows for faster turnaround times, enabling businesses to meet tight deadlines and deliver results in a timely manner.Furthermore, the Fiber Laser Printer is designed to be user-friendly and efficient, making it an ideal choice for both large-scale production facilities and small businesses. Its intuitive interface and advanced features enable users to produce high-quality prints with ease, while its reliable performance ensures consistent results with minimal downtime.The company behind the development of the Fiber Laser Printer has a long-standing reputation for innovation and excellence in the printing industry. With a dedication to pushing the boundaries of printing technology, the company has continuously invested in research and development to bring cutting-edge solutions to the market.The company's commitment to quality and customer satisfaction has made it a trusted name in the industry, with a proven track record of delivering top-of-the-line printing solutions. Its team of experienced professionals and engineers have worked tirelessly to develop the Fiber Laser Printer, leveraging their expertise to create a product that exceeds industry standards.Moreover, the company has also focused on sustainability and eco-friendly practices, ensuring that its printing solutions are not only efficient but also environmentally responsible. The Fiber Laser Printer is designed to minimize waste and energy consumption, making it a sustainable choice for businesses looking to reduce their environmental footprint.As the printing industry continues to evolve, the Fiber Laser Printer represents a significant advancement that will shape the future of printing technology. Its exceptional capabilities, combined with the company's commitment to innovation and quality, have positioned it as a leader in the industry, setting a new standard for high-quality printing solutions.With its ability to deliver superior print quality, high-speed production, and user-friendly operation, the Fiber Laser Printer has quickly become the preferred choice for businesses looking to elevate their printing capabilities. As the demand for advanced printing solutions continues to grow, the Fiber Laser Printer is poised to make a lasting impact and solidify its position as an industry-leading technology.

High-Quality Welding Machine Board for Efficient Welding Operations

Welding Machine Board: The Latest Innovation in Welding TechnologyIn the world of industrial manufacturing, welding is an essential process that is used to join different metal components together. As technology continues to advance, the welding industry has seen significant innovations that have improved the efficiency and quality of the welding process. One such innovation is the welding machine board, a cutting-edge technology that is revolutionizing the welding industry.The welding machine board, developed by an industry-leading manufacturer, is a state-of-the-art electronic control system that is designed to enhance the performance and precision of welding machines. This innovative technology is equipped with advanced features that allow for superior arc control, improved welding performance, and increased productivity. With the welding machine board, welders have the ability to fine-tune their welding parameters and achieve optimal welding results with ease.The company behind the development of the welding machine board is a well-established and reputable manufacturer of welding equipment. With a history of delivering high-quality products and innovative solutions, the company has earned a strong reputation in the welding industry. Their commitment to excellence and continuous improvement has led to the development of the welding machine board, a game-changing technology that is setting new standards in the welding industry.The welding machine board is designed to be compatible with a wide range of welding machines, making it a versatile and adaptable solution for different welding applications. Whether it is used for manual, semi-automatic, or fully automated welding processes, the welding machine board is capable of delivering exceptional performance and precise control.One of the key benefits of the welding machine board is its ability to improve the quality and consistency of welds. By providing advanced arc control and monitoring capabilities, the technology ensures that welds are produced with the highest level of precision and quality. This is particularly important in industries where weld quality is critical, such as automotive manufacturing, aerospace, and construction.In addition to enhancing weld quality, the welding machine board also offers significant improvements in productivity and efficiency. With its intuitive interface and user-friendly controls, welders can easily adjust welding parameters and optimize their welding processes for maximum efficiency. This not only saves time and labor costs but also allows for higher throughput and increased production capacity.Furthermore, the welding machine board is equipped with advanced monitoring and diagnostic features that provide real-time feedback and insights into the welding process. This allows operators to identify and address any issues or anomalies promptly, ensuring that the welding process runs smoothly and efficiently.Overall, the welding machine board represents a significant advancement in welding technology and is poised to have a profound impact on the welding industry. With its unparalleled performance, precision control, and productivity enhancements, the technology is set to become an indispensable tool for welders and manufacturers alike.As the company continues to lead the way in innovation and technological advancement, the welding machine board is a testament to their commitment to providing cutting-edge solutions that meet the evolving needs of the welding industry. With its proven track record of delivering high-quality products and exceptional customer support, the company is well-positioned to drive the adoption of the welding machine board and shape the future of welding technology.In conclusion, the welding machine board is a groundbreaking technology that is poised to redefine the welding industry. With its advanced features, performance enhancements, and compatibility with a wide range of welding machines, the technology is set to revolutionize the way welders approach their work. As the company behind this innovation continues to push the boundaries of welding technology, the welding machine board is undoubtedly a game-changer that will shape the future of welding for years to come.

Affordable Laser Number Plate Prices: Get Your Customized License Plate Today

Laser Number Plate Price Slashed by Leading ManufacturerIn a bid to make laser number plates more affordable for customers, a leading manufacturer has announced a significant reduction in the price of their top-quality laser number plates. This move is expected to make these high-tech number plates more accessible to a wider customer base, ultimately enhancing road safety and compliance with regulations.{The company} is renowned for its innovative and cutting-edge products in the automotive industry. With a strong focus on quality and customer satisfaction, {the company} has established itself as a market leader in the manufacturing of number plates and other automotive accessories. The company's commitment to excellence and continuous improvement has earned them a stellar reputation in the industry.The decision to reduce the price of laser number plates comes as a response to the growing demand for these advanced products. Laser number plates offer several advantages over traditional number plates, including superior durability, enhanced visibility, and resistance to tampering and theft. These features make them an attractive option for vehicle owners looking for a reliable and long-lasting solution for their number plate needs.By lowering the price of laser number plates, {the company} aims to make them more accessible to a wider range of customers. This move is expected to drive increased adoption of laser number plates, ultimately contributing to improved road safety and compliance with regulations. As a result, vehicle owners will be able to enjoy the benefits of these high-quality number plates at a more affordable price point.The reduced price of laser number plates from {the company} will also make it easier for businesses, fleet operators, and government agencies to invest in these advanced products. With the potential for bulk purchases at a lower cost, these entities can equip their vehicles with laser number plates, thereby enhancing their overall operational efficiency and compliance with regulatory requirements.Furthermore, {the company}'s decision to lower the price of laser number plates underscores its commitment to providing value to customers. By offering top-quality products at a more competitive price, {the company} is demonstrating its dedication to customer satisfaction and market leadership. This move is aligned with the company's core values and vision for the future of the automotive industry.In addition to reducing the price of laser number plates, {the company} continues to uphold its high standards of product quality and performance. The company's laser number plates are manufactured using state-of-the-art technology and premium materials, ensuring their longevity and reliability on the road. Customers can trust {the company} to deliver products that meet and exceed industry standards.{The company} remains at the forefront of innovation in the automotive industry, constantly exploring new possibilities and pushing the boundaries of what is possible. The company's dedication to research and development has resulted in the creation of groundbreaking products such as laser number plates, which offer unmatched durability and security features. With a track record of excellence, {the company} is poised to continue shaping the future of the automotive market.In conclusion, the decision to slash the price of laser number plates by {the company} is a significant development that will benefit customers and the automotive industry as a whole. By making these advanced number plates more affordable, {the company} is opening up new opportunities for vehicle owners, businesses, and government agencies to enhance road safety and compliance. This move reflects {the company}'s commitment to excellence, customer satisfaction, and innovation, positioning the company as a true leader in the automotive industry.