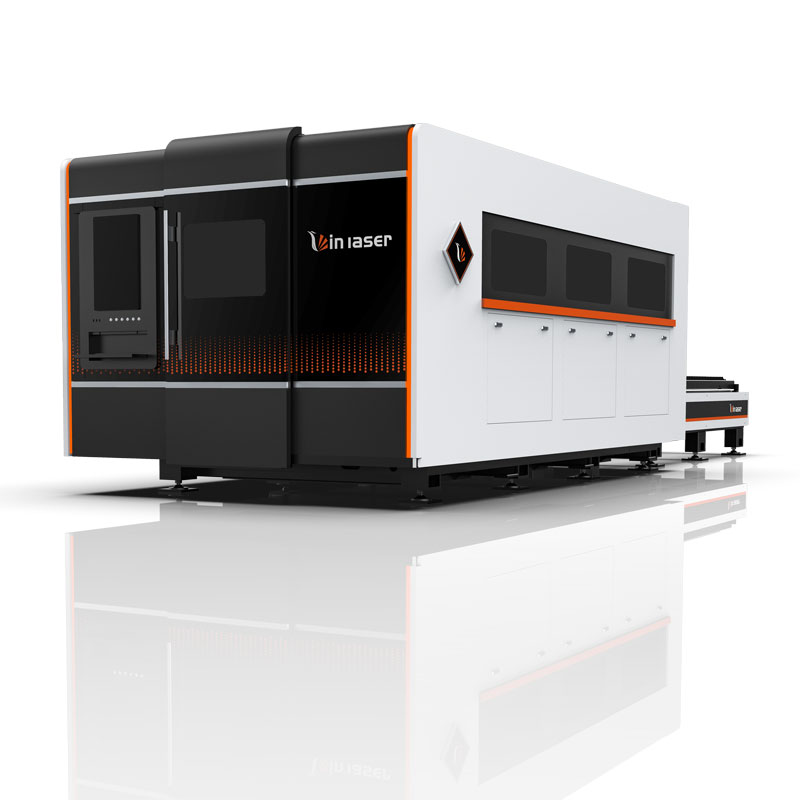

Advanced Cutting System: New Technology for Precision and Efficiency

By:Admin

The manufacturing industry is constantly evolving, with new technologies and innovations driving efficiency and productivity. One such innovation is the cutting system developed by a leading manufacturing company. This cutting system is revolutionizing the industry, offering precision and speed like never before.

The cutting system, developed by the company, is a state-of-the-art solution for cutting various materials with unmatched accuracy. It utilizes advanced technology and high-quality materials to deliver precise cuts, making it ideal for a wide range of applications in the manufacturing industry.

With a focus on innovation and cutting-edge technology, the company has been at the forefront of manufacturing solutions for decades. Their cutting system is the latest addition to their impressive lineup of products, and it is quickly gaining recognition for its exceptional performance and reliability.

One of the key features of the cutting system is its versatility. It is capable of cutting a wide range of materials, including metal, plastic, and composites, with exceptional precision. This versatility makes it a valuable tool for manufacturers across various industries, from automotive and aerospace to consumer goods and electronics.

In addition to its versatility, the cutting system also offers unmatched speed and efficiency. It is equipped with advanced software and automation capabilities that streamline the cutting process, reducing production time and increasing throughput. This level of speed and efficiency is crucial for manufacturers looking to stay competitive in today's fast-paced market.

Furthermore, the cutting system is designed with user-friendly features that make it easy to operate and maintain. Its intuitive interface and comprehensive support resources make it accessible to operators of all skill levels, ensuring that manufacturers can maximize the system's potential without extensive training or technical expertise.

The company has also prioritized safety in the design of the cutting system, incorporating protective measures to safeguard operators and prevent accidents. This commitment to safety reflects the company's dedication to providing not only high-performance solutions but also reliable and secure tools for the manufacturing industry.

The cutting system is also supported by a team of experts who are available to provide technical assistance, training, and guidance to users. This level of support ensures that manufacturers can make the most of the system and address any challenges or issues that may arise.

As a result of its exceptional performance and reliability, the cutting system has garnered widespread praise from manufacturers who have implemented it into their production processes. Customer testimonials and case studies have highlighted the system's ability to significantly improve precision, efficiency, and overall productivity.

In summary, the cutting system developed by the company is a game-changer for the manufacturing industry. Its precision, speed, versatility, and user-friendly design make it a valuable asset for manufacturers across various sectors. As the industry continues to evolve, this cutting system is poised to play a crucial role in driving efficiency and innovation for years to come.

Company News & Blog

High-Powered Fiber Laser Engraver Offers Precise Engraving Capabilities

Fiber Laser Engraver: A revolution in precision engravingIn today's fast-paced, technology-driven world, precision and efficiency are key factors in the manufacturing and engraving industries. The introduction of fiber laser engraving technology has revolutionized the way companies engrave their products, offering a level of precision and speed that was previously unattainable. This cutting-edge technology has been at the forefront of the engraving industry, allowing businesses to create intricately detailed engravings on a wide range of materials, from metal to plastic, with unparalleled accuracy.One company that has been leading the way in the development and implementation of fiber laser engraving technology is {}. With years of experience and expertise in the engraving industry, {} has been instrumental in bringing this game-changing technology to the forefront of the market. By combining their extensive knowledge of engraving processes with the latest advancements in fiber laser technology, {} has been able to offer their clients a cutting-edge solution that delivers exceptional results with unmatched precision and speed.The fiber laser engraving technology utilized by {} is a non-contact process that uses a high-intensity laser beam to precisely remove material from the surface of an object, leaving behind a permanent and highly detailed engraving. This advanced technology allows for the creation of complex designs, patterns, and text with extraordinary precision, making it ideal for a wide range of applications, including industrial part marking, jewelry engraving, medical device manufacturing, and more.One of the key advantages of fiber laser engraving is its versatility and ability to work with a wide range of materials. Whether it's metal, plastic, glass, or even ceramics, the technology employed by {} can create crisp and clear engravings on virtually any surface. This level of flexibility has made fiber laser engraving an essential tool for businesses across a wide range of industries, as it allows for the creation of high-quality, custom engravings on a diverse array of products.In addition to its versatility, fiber laser engraving also offers unmatched speed and efficiency. Thanks to the precision and power of the laser beam, {} can complete engravings in a fraction of the time it would take using traditional engraving methods. This not only allows for higher productivity and throughput but also results in cost savings for businesses, as they are able to produce more engravings in less time.Another significant advantage of fiber laser engraving is its ability to create durable and long-lasting engravings that are resistant to wear and tear. Unlike surface coatings or traditional engraving methods, the engravings created by {} do not degrade over time and are highly resistant to fading, scratching, and corrosion. This makes fiber laser engraving an ideal solution for applications requiring durable and permanent markings, such as part serialization, branding, and product identification.Furthermore, {}'s fiber laser engraving technology also offers environmental benefits, as it is a clean and efficient process that eliminates the need for harsh chemicals or consumables. This means that businesses can enjoy a more sustainable and eco-friendly engraving solution that minimizes waste and reduces their environmental impact.The advancements made by {} in the field of fiber laser engraving have significantly raised the bar for precision engraving technology, offering businesses a cutting-edge solution that delivers exceptional results with unparalleled speed, accuracy, and versatility. As the demand for high-quality, custom engravings continues to grow across a wide range of industries, fiber laser engraving is poised to play a pivotal role in shaping the future of the engraving industry, and companies like {} are at the forefront of this technological revolution.

Affordable Laser Machines for Your Business

Cheap Lin Laser Machine Revolutionizes the Manufacturing IndustryIn recent years, the manufacturing industry has seen a significant shift towards the use of advanced technology to improve efficiency, precision, and cost-effectiveness. One such technological innovation that has been making waves in the industry is the Cheap Lin Laser Machine. This state-of-the-art machine has been revolutionizing the manufacturing process, allowing companies to elevate their production capabilities to new heights.The Cheap Lin Laser Machine, produced by an industry-leading company, is a high-performance laser cutting and engraving machine that has been designed to cater to the diverse needs of manufacturers across various industries. The machine boasts cutting-edge technology, precision engineering, and a user-friendly interface, making it an invaluable asset for businesses of all sizes.With the ability to cut a wide range of materials, including metal, wood, plastic, and more, the Cheap Lin Laser Machine offers unparalleled versatility and flexibility. Whether a company is involved in the production of intricate metal parts, custom signage, or personalized gifts, this machine is capable of delivering exceptional results with utmost precision.One of the distinct advantages of the Cheap Lin Laser Machine is its affordability without compromising on quality or performance. In an industry where the cost of advanced machinery can be a significant barrier for small and medium-sized businesses, this machine has proven to be a game-changer. By providing access to cutting-edge technology at a competitive price point, the Cheap Lin Laser Machine has empowered businesses to enhance their production capabilities and remain competitive in the market.The company behind the Cheap Lin Laser Machine understands the evolving needs of the manufacturing industry and is committed to providing innovative solutions that meet those needs. With a focus on quality, reliability, and customer satisfaction, the company has established itself as a trusted partner for businesses looking to invest in advanced laser cutting and engraving technology.The Cheap Lin Laser Machine is equipped with advanced features that streamline the manufacturing process and deliver exceptional results. Its powerful laser technology ensures fast and precise cutting, while the user-friendly interface makes it easy for operators to set up and execute complex cutting and engraving tasks.Furthermore, the machine’s robust construction and durable components make it a reliable workhorse that can withstand the demands of a busy production environment. With minimal maintenance requirements and a long lifespan, the Cheap Lin Laser Machine offers excellent value for money and a solid return on investment for businesses.In addition to its technical capabilities, the company provides comprehensive customer support and training to ensure that businesses can maximize the potential of the Cheap Lin Laser Machine. From installation and setup to ongoing technical assistance, the company is dedicated to helping its customers harness the full capabilities of the machine and achieve their production goals.As the manufacturing industry continues to embrace technological advancements, the Cheap Lin Laser Machine stands out as a game-changing innovation that is reshaping the way businesses approach laser cutting and engraving. Its affordability, performance, and versatility have made it a popular choice for manufacturers looking to elevate their production capabilities and take their business to the next level.With a commitment to innovation, quality, and customer satisfaction, the company behind the Cheap Lin Laser Machine is poised to lead the industry in providing cutting-edge solutions that empower businesses to thrive in a competitive market. As the demand for advanced laser cutting and engraving technology continues to grow, the Cheap Lin Laser Machine is set to play a pivotal role in shaping the future of manufacturing.

Innovative Fiber Laser Cutting Machine for High Precision and Speed Metal Cutting

: Advantages and ApplicationsFiber laser CNC machines are becoming increasingly popular in the metal cutting industry due to their high speed, precision, and efficiency. They use a powerful fiber laser generator to cut and punch through different types of metal materials with ease. In this article, we will explore the advantages and applications of CNC fiber laser cutting machines.Advantages of Fiber Laser CNC Machines:1. High Precision - Fiber laser CNC machines are designed for high precision cutting and punching. They use a tiny laser beam that produces a narrow kerf width, allowing for precise and accurate cuts. The laser beam’s intensity can be adjusted to produce high-quality, smooth cuts every time.2. High Speed - Fiber laser CNC machines are incredibly fast. Thanks to advanced fiber laser technology and ball screw moving systems, they can cut through metal materials at incredible speeds, reducing lead time and increasing productivity.3. Low Maintenance - Unlike other traditional laser cutting machines, fiber laser CNC machines require minimal maintenance. They have fewer moving parts, which means fewer parts to maintain or replace. This results in lower maintenance costs and higher uptime for the machine.4. Versatile - CNC fiber laser machines can cut and punch through various metal materials, including steel, aluminum, brass, and copper. They can also cut through thick materials up to approximately 30mm in thickness, making them ideal for a broad range of applications.Applications of Fiber Laser CNC Machines:1. Manufacturing - CNC fiber laser machines are widely used in the manufacturing industry for cutting and punching various metal components, including sheet metal, brackets, automotive parts, and many more.2. Advertisement - The fiber laser CNC machine can also be used in the advertising industry for cutting and engraving various materials like acrylic, wood, and plastic.3. Aerospace - The aerospace industry uses fiber laser CNC machines for cutting and punching metal components, including engine parts, wings, and fuselage.4. Medical - The medical industry uses CNC fiber laser machines for cutting and marking medical devices and instruments, such as surgical tools, implants, and stents.Conclusion:Fiber laser CNC machines are high-speed, efficient, and precise metal cutting machines. They have minimal maintenance requirements and can handle a wide range of materials. They are ideal for various industries, including manufacturing, aerospace, medical, and advertisement. If you are looking for a CNC machine that can improve your productivity and reduce costs, consider investing in a fiber laser CNC machine.

Types of Welding Machines: Applications and Functions

: What They Are and How They Work.Welding machines are a vital tool in the metalworking industry. They work by applying heat to a metal surface until it melts and joins with another piece of metal. There are many different types of welding machines, each suited to specific tasks and materials. However, one type of welding machine that stands out is the easy welding machine.The easy welding machine is a compact, lightweight device that is ideal for small to medium welding projects. It is designed for DIY enthusiasts and beginners who want a straightforward and easy-to-use machine. It is also an excellent choice for those who need to do occasional repairs at home or in a workshop.One of the significant advantages of the easy welding machine is that it is easy to set up and use. Unlike more complicated machines that require extensive training and experience to operate, an easy welding machine is straightforward to use. It comes with clear instructions and straightforward controls, making it easy for anyone to start welding in no time.The easy welding machine uses a process called arc welding. This process works by creating an electric arc between the metal being welded and a welding electrode. The heat generated by the arc melts the metal, creating a pool of molten metal. As the metal cools, it solidifies, forming a strong weld joint.One of the key benefits of using an easy welding machine for arc welding is that it is incredibly versatile. It can weld a wide range of materials, including mild steel, stainless steel, and aluminum. This makes it an ideal tool for a wide range of applications, from repairing metal fences and gates to building custom metal structures.Another advantage of the easy welding machine is its portability. It is small and lightweight, making it easy to move around and transport to different locations. This makes it an excellent tool for those who work on the go or need to weld in tight spaces.Finally, the easy welding machine is affordable. It is an excellent tool for those on a budget or those who only need to do occasional welding. Despite its affordability, it is still a high-quality tool that delivers reliable results.In conclusion, an easy welding machine is an excellent tool for those who want to start welding or need to do occasional repairs. It is easy to set up and use, versatile, portable, and affordable. If you're looking for a straightforward and reliable welding machine, consider an easy welding machine.

Efficient Plate Cleaning Machine for Chinese Restaurants

China Plate Cleaning Machine, a leading manufacturer in the field of industrial cleaning equipment, has recently announced the launch of its latest product, the Plate Cleaning Machine. This cutting-edge machine is designed to provide efficient and effective cleaning for a wide range of industrial plates, making it an essential tool for businesses in the manufacturing and food processing industries.The Plate Cleaning Machine is equipped with advanced technology that allows for thorough and precise cleaning of various types of plates, including metal, plastic, and glass. With its powerful water jets and adjustable pressure settings, the machine can effectively remove stubborn dirt, grease, and grime from the surface of the plates, ensuring that they are completely clean and ready for use in the production process.In addition to its exceptional cleaning capabilities, the Plate Cleaning Machine also features a user-friendly interface that allows for easy operation and customization. The machine can be programmed to accommodate different plate sizes and cleaning requirements, making it a versatile and adaptable solution for businesses of all sizes."We are thrilled to introduce the Plate Cleaning Machine to the market," said a spokesperson for China Plate Cleaning Machine. "We understand the importance of maintaining clean and sanitary conditions in industrial settings, and our new machine is designed to meet and exceed the highest standards of cleanliness. With its cutting-edge technology and user-friendly design, we believe that the Plate Cleaning Machine will be a valuable asset for businesses looking to streamline their cleaning processes and improve overall efficiency."In addition to its innovative features, the Plate Cleaning Machine is also designed with durability and reliability in mind. Constructed from high-quality materials and built to withstand heavy use, the machine is engineered to provide long-term performance and minimal maintenance requirements, ensuring that businesses can depend on it for years to come.To further support its customers, China Plate Cleaning Machine also offers comprehensive customer service and technical support for the Plate Cleaning Machine. From installation and training to ongoing maintenance and troubleshooting, the company is committed to ensuring that its customers are able to fully maximize the potential of the machine and achieve the best possible results.The introduction of the Plate Cleaning Machine reflects China Plate Cleaning Machine's ongoing commitment to innovation and excellence in the field of industrial cleaning equipment. With its state-of-the-art technology, user-friendly design, and exceptional performance, the machine is poised to set a new standard for plate cleaning in industrial settings and provide significant benefits for businesses looking to enhance their cleaning processes."We are dedicated to providing our customers with the most advanced and reliable cleaning solutions, and the Plate Cleaning Machine is a testament to that commitment," the spokesperson added. "We are confident that this machine will make a significant impact in the industry and help businesses achieve higher levels of cleanliness, productivity, and efficiency."For businesses in the manufacturing and food processing industries, the Plate Cleaning Machine from China Plate Cleaning Machine offers a powerful and versatile solution for achieving the highest standards of cleanliness and sanitation for industrial plates. With its advanced technology, user-friendly design, and commitment to customer support, the machine is set to become an essential tool for businesses seeking to optimize their cleaning processes and enhance overall performance.

Minimizing Laser Cutting Focus Shift with New Algorithm and Non-Contact Beam Measurement Platform

Messer Cutting Systems, a leading company in the manufacturing and supply of high-quality cutting-edge technologies and systems for various industries, has recently introduced a new algorithm that has the capability of reducing the focus shift in laser cutting systems to a minimum. This advanced technology coupled with a new noncontact beam measurement platform has been developed using the most up-to-date fiber laser technology.The company's new algorithm has been designed to reduce the focus shift produced in a laser cutting process. The focus shift created in the process is the result of thermal changes. Thermal changes cause a shift in the focus point of a laser beam and this ultimately leads to poor quality cuts. The shift in the laser focal point can have an impact on the quality and quantity of cuts made, thus making it a critical challenge in the laser cutting industry.To address this challenge, Messer Cutting Systems has introduced an advanced noncontact beam measurement system that integrates seamlessly with the existing fiber laser technologies. This new measurement system has been designed to measure the beam power, beam quality, and beam position, thus providing a complete overview about the current status of the laser beam. The new noncontact beam measurement platform helps to monitor and correct the focus shift in the laser cutting machines, which is designed to offer exceptional precision and accuracy in the cutting process.Messer Cutting Systems is known for its continuous innovations and research and development in the industry. The company has an experienced team of engineers and scientists, who are experts in their respective fields, to meet the needs and requirements of their customers. This has enabled the company to develop and produce high-quality laser cutting systems that are specifically engineered to meet the precise needs of their clients.In addition, the company has also introduced another innovative technology that sets it apart from the conventional laser cutting systems. The new technology is a "smart" cutting technology that reduces the operating costs involved in the laser cutting process. The system can cut down on the amount of wasted material and reduce energy costs, resulting in lower production costs and enhanced production efficiency. The intelligent technology uses sensors and cameras to scan the material, and then optimizes the cutting patterns based on the material characteristics.Messer Cutting Systems is committed to providing a complete range of laser cutting solutions in various industries, including automotive, defense, aerospace, energy, and more. With state-of-the-art technology and advanced laser cutting systems, the company is poised for growth and is highly focused on continually developing new and innovative technologies that push the boundaries of the laser cutting industry.In conclusion, Messer Cutting Systems is an innovative and visionary company that is at the forefront of the laser cutting industry. The company has introduced advanced technologies that not only address the challenges faced by the industry but also provide smart solutions that enable higher productivity, better quality, and lower costs. With its continued dedication to innovation and customer satisfaction, Messer Cutting Systems is poised for future growth and success.

Automatic Fabric Textile Knife Cutting Machine for Garment and Footwear Production at Factory Price – Non-Laser Die System

, Mats Cutting Machine, CNC Automatic High Speed Cloth Garment Shoe Footwear Making Machine, Fabric Textile Knife Cutting, Leather Processing, Digital Plotter, Factory Price, Not Laser Die.CNC Automatic High Speed Cloth Garment Shoe Footwear Making Machine Fabric Textile Knife Cutting Leather Processing Digital Plotter Fabctory Price Not Laser DieIn today's fast-paced world, businesses require cutting-edge technology to keep up with the ever-changing demands of the market. CNC automatic high-speed cloth garment shoe footwear making machine fabric textile knife cutting leather processing digital plotter factory price not laser die is the latest innovation that has transformed the textile and garment industry. This machine is capable of cutting various fabrics, leathers and textiles, providing precision and accuracy in every cut.The machine has been designed to cater to the needs of various industries, including the garment, shoe, and footwear industries. The cutting tool is made of a specialized knife that is durable and able to cut through fabrics seamlessly. The CNC automatic high-speed cloth garment shoe footwear making machine is a versatile equipment that can handle various fabrics such as cotton, silk, wool, polyester, leather, and synthetic materials.One of the significant advantages of the CNC automatic high-speed cloth garment shoe footwear making machine is its digital plotter. The digital plotter allows for the customization of designs to match the client's needs. The digital technology also ensures that the machine produces intricate designs that are unique and of high quality. Clients can submit their designs and specifications, and the machine will work on the designs accurately, providing high-quality output.The CNC automatic high-speed cloth garment shoe footwear making machine has a cutting speed of up to 1200 mm/s. This speed is critical in large scale production as the machine is capable of producing a massive number of cuts within a short time. The speed of the machine also guarantees that there is no wastage of materials, which reduces the costs of production. The high speed also helps in meeting tight deadlines.The machine's factory price is also another advantage that businesses can enjoy. The factory price is relatively low, making the machine an affordable option for both small and large businesses. The low price does not compromise on the quality and functionality of the machine, making it an ideal option for businesses that are looking to reduce costs while maintaining high-quality output.Another major advantage of the CNC automatic high-speed cloth garment shoe footwear making machine is that it uses a knife cutting system as opposed to laser cutting. The knife cutting system has proven to be more efficient and precise in cutting fabrics as it eliminates the risk of burning or melting the fabric. It also eliminates any chemical waste that may result from laser cutting and is thus an eco-friendly option.In summary, the CNC automatic high-speed cloth garment shoe footwear making machine fabric textile knife cutting leather processing digital plotter factory price not laser die is a significant innovation that has transformed the textile and garment industry. Its high speed, accuracy, and customization options make it an ideal option for both small and large business ventures. With this machine, businesses can reduce production costs while maintaining high-quality output. The knife cutting system is also eco-friendly, making it a responsible technology choice. For businesses looking to stay ahead of the competition, investing in the CNC automatic high-speed cloth garment shoe footwear making machine is a smart decision.

Advanced 2D Flat Laser Cutting Services for High-Volume Production Projects

article about the latest advancements in laser cutting.Summit Steel & Manufacturing, Inc. has been known for delivering high-quality metal fabrications and machining solutions. Their latest advancement in laser cutting technology has allowed them to deliver excellent results for high-volume production projects. The 2D flat laser cutting process is a game-changer in the manufacturing industry, delivering smooth, clean edges, tight tolerances, and consistent results.With Summit Steel & Manufacturing, Inc.'s state-of-the-art laser cutting system, you can easily upload your prints or DXF files. The system's advanced technology allows for fast and efficient material utilization, resulting in enhanced productivity. The high precision of the laser cutting process ensures that every project is executed to perfection. This precision is what sets Summit Steel & Manufacturing, Inc. apart from its competitors.Laser cutting, in general, involves cutting a material using a high-powered laser beam. The laser beam is directed by a computer that controls its position, power, speed, and duration. This process is perfect for a wide range of materials, including metals, plastics, glass, and ceramics. This versatility has led to an increase in the use of laser cutting technology in various industries.One significant benefit of laser cutting technology is its high accuracy. The accuracy of laser cutting is unmatched compared to other cutting technologies. Laser cutting is also known for its speed, which is one of its significant advantages. Cutting a material using traditional methods can take a lot of time. Laser cutting technology speeds the process considerably, thus making it an ideal solution for high-volume production projects.Laser cutting technology is also environmentally friendly. With no toxic chemicals or gases involved in the process, laser cutting produces minimal waste. Additionally, the unit cost of laser cutting is lower compared to other traditional cutting methods, making it an economical option.Apart from the advantages mentioned earlier, laser cutting technology has advanced significantly over the years. The latest technology introduces new features that make the process even more efficient and precise. For example, some of the latest laser cutting technologies come with a fiber-optic laser cutting system, which can cut materials much faster than traditional laser cutting machines.Summit Steel & Manufacturing, Inc.'s laser cutting system also comes with an automatic nozzle changer. This feature makes it possible to shift from one cutting application to another with ease. The system also boasts an offline programming capability, enabling the operator to program the machine on a different computer while the machine is still in use.Laser cutting technology is very versatile, and its applications are endless. In the automotive industry, the technology can be used to cut metal parts, such as exhaust systems or brackets used in the engine. In the aerospace industry, laser cutting technology can be used to cut aircraft parts, such as cockpit and fuselage parts. Laser cutting technology is also used to manufacture electronic components, signage, and jewelry.In conclusion, Summit Steel & Manufacturing, Inc.'s latest advancement in laser cutting technology is a game-changer. The 2D flat laser cutting process delivers smooth, clean edges, tight tolerances, and consistent results, making it perfect for high-volume production projects. The precision, speed, and flexibility offered by laser cutting technology make it a versatile solution for a wide range of applications. As technology continues to evolve, laser cutting technology will become even more efficient, and its applications will continue to expand.

Understanding the Different Classes of Laser for Safety and Regulations

Laser Classification Guide: Understanding Laser Classes and Safety MeasuresLaser technology has revolutionized various industries, from healthcare and manufacturing to entertainment and telecommunications. However, the misuse of lasers can pose serious risks to human safety and the environment. To address these concerns, the International Electrotechnical Commission (IEC) has established a classification system to categorize lasers based on their potential hazards.Understanding Laser ClassesThe IEC classification system divides lasers into four main classes: Class 1, Class 2, Class 3, and Class 4, with Class 1 being the least hazardous and Class 4 posing the greatest risk. Each class is based on the laser's potential for causing eye and skin injuries, with Class 3 and Class 4 lasers also posing a potential fire hazard.Class 1 lasers are considered safe under normal operating conditions and do not pose a risk of eye damage. Many consumer products, such as laser printers and DVD players, fall into this category.Class 2 lasers are low-power visible lasers that are only hazardous if the eye is exposed directly to the beam for an extended period of time. This class includes laser pointers and barcode scanners.Class 3 lasers are divided into two subcategories: Class 3R and Class 3B. Class 3R lasers are considered safe for brief, accidental exposures, while Class 3B lasers can cause eye injuries if viewed directly. These lasers are commonly used in research, medical, and industrial applications.Finally, Class 4 lasers are high-power lasers that can cause severe eye and skin injuries, as well as ignite flammable materials. These lasers are used in industrial cutting and welding, as well as in medical procedures.Company Introduction{} is a leading provider of laser technology solutions, specializing in the design, manufacturing, and distribution of a wide range of lasers for various applications. With a strong focus on innovation and safety, {} is committed to ensuring that its products meet the highest standards of quality and compliance with regulatory requirements.In addition to producing state-of-the-art lasers, {} also offers comprehensive training and support services to help customers understand the potential hazards associated with laser operation and implement appropriate safety measures.Ensuring Laser SafetyWhen working with lasers, it is essential to take appropriate safety precautions to minimize the risk of accidents and injuries. This includes wearing appropriate eye protection, implementing engineering controls to prevent accidental exposure to laser beams, and following established safety procedures for laser operation and maintenance.In addition, laser operators should be properly trained on the safe use of lasers and be aware of the potential hazards associated with different laser classes. By understanding the risks and taking proactive measures to mitigate them, companies can create a safe working environment for their employees and minimize the potential impact on the surrounding community.Compliance with Regulatory RequirementsIn many countries, the use of lasers is subject to strict regulatory requirements to ensure public safety. These regulations may include mandatory laser classification, labeling, and documentation of safety measures. It is essential for companies to stay informed about these requirements and ensure that their laser systems comply with relevant standards and regulations.As a responsible provider of laser technology solutions, {} is dedicated to supporting its customers in understanding and meeting regulatory requirements to ensure the safe and compliant use of its products.Looking to the FutureAs laser technology continues to advance and find new applications across industries, the importance of laser safety and compliance will remain a critical concern. By staying informed about the latest developments in laser classification and safety measures, companies can ensure that they are taking the necessary steps to protect their employees, customers, and the environment.With its ongoing commitment to innovation and safety, {} is well-positioned to support its customers in addressing these challenges and leveraging the full potential of laser technology in a safe and responsible manner.With the rapid evolution of laser technology, it is crucial for companies to prioritize safety and compliance in their use of lasers. By understanding laser classification and implementing appropriate safety measures, businesses can harness the power of lasers while minimizing potential risks. As a leading provider of laser technology solutions, {} remains dedicated to supporting its customers in this endeavor, ensuring that their laser operations meet the highest standards of safety and compliance.

Powerful 130w CO2 Laser: What You Need to Know

Laser Co2 130w: A Revolutionary Technology in the Manufacturing IndustryIn recent years, the manufacturing industry has witnessed a significant shift towards advanced and efficient technologies. One such breakthrough technology is the Laser Co2 130w, which has revolutionized the manufacturing process by offering high precision and speed. The Laser Co2 130w is a cutting-edge technology that has been gaining widespread recognition for its exceptional performance and versatility.{} is one of the leading companies at the forefront of introducing Laser Co2 130w technology into the manufacturing industry. With our commitment to innovation and excellence, we have successfully integrated this advanced technology into our manufacturing processes, delivering superior quality products to our clients.The Laser Co2 130w technology is a powerful tool that utilizes a high-powered laser to cut and engrave various materials with precision and accuracy. This technology is widely used in industries such as automotive, aerospace, electronics, and medical device manufacturing, where precision and speed are of utmost importance. The versatility of the Laser Co2 130w allows for the cutting and engraving of materials such as wood, acrylic, glass, leather, and many others, making it an essential tool for a wide range of applications.One of the key advantages of the Laser Co2 130w is its high cutting speed, which significantly reduces production time and increases efficiency. This technology also offers a high level of precision, allowing for intricate and detailed designs to be cut or engraved with incredible accuracy. Additionally, the Laser Co2 130w is equipped with advanced features such as autofocus, which ensures consistent cutting depth and quality across the entire surface of the material.At {}, we have embraced the Laser Co2 130w technology to enhance our manufacturing capabilities and deliver exceptional results to our customers. By utilizing this cutting-edge technology, we have been able to expand our product offerings and meet the growing demands of the market. The Laser Co2 130w has enabled us to streamline our manufacturing processes, reduce production costs, and improve the overall quality of our products.In addition to its remarkable performance, the Laser Co2 130w is also an environmentally friendly technology. By using a high-powered laser to cut and engrave materials, this technology eliminates the need for traditional cutting methods that produce waste and environmental pollution. With the Laser Co2 130w, we are able to minimize our environmental impact and contribute to a sustainable manufacturing process.The integration of the Laser Co2 130w into our manufacturing operations has allowed us to stay ahead of the competition and set new standards for quality and efficiency. As a result, we have gained a competitive edge in the market and established ourselves as a leader in the manufacturing industry.As we look to the future, we are committed to further enhancing our capabilities with the latest technologies and innovations. The Laser Co2 130w has been a game-changer for us, and we are dedicated to exploring new possibilities and pushing the boundaries of what is possible in manufacturing.In conclusion, the Laser Co2 130w technology has brought about a paradigm shift in the manufacturing industry, offering unprecedented levels of precision, speed, and efficiency. At {}, we are proud to be at the forefront of this technological revolution and are excited about the endless possibilities it presents for our business and the industry as a whole. With our commitment to excellence and innovation, we are confident that the Laser Co2 130w will continue to shape the future of manufacturing for years to come.