5 Tips for Effective Content Processing

By:Admin

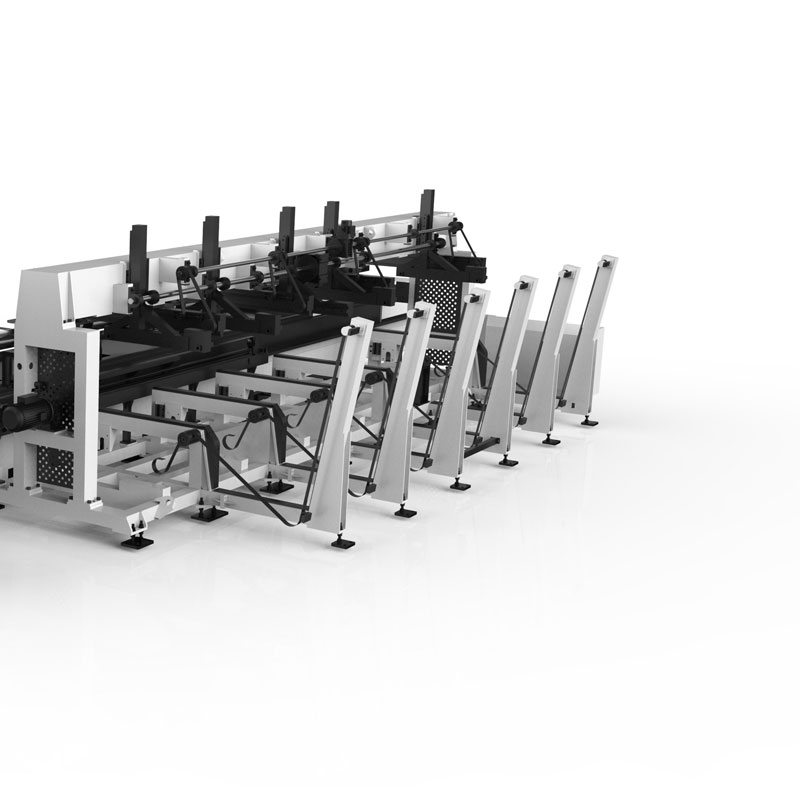

The new product from Processing Pipe is designed to streamline the process of creating and implementing processing systems for a wide range of industrial applications. It offers a range of advanced features that are specifically tailored to the needs of modern manufacturing facilities, including enhanced automation capabilities, improved data analytics, and seamless integration with existing equipment and processes. These features are designed to help manufacturers improve the efficiency, reliability, and overall performance of their processing systems, while minimizing downtime and maintenance costs.

One of the key benefits of this new product is its advanced automation capabilities, which allow manufacturers to greatly reduce the need for manual intervention in their processing systems. This not only helps to improve efficiency and speed up production processes, but also reduces the risk of human error and improves overall system reliability. By automating key aspects of their processing systems, manufacturers can also free up valuable resources and manpower to focus on more strategic and value-added tasks, such as process optimization and product development.

In addition to its automation capabilities, the new product from Processing Pipe also offers enhanced data analytics functionality. This allows manufacturers to gain deeper insights into their processing systems, identify potential areas for improvement, and make informed decisions about how to optimize their operations. By providing real-time data and analytics, the new product can help manufacturers identify inefficiencies, reduce waste, and improve overall production output.

Furthermore, the new product is designed to seamlessly integrate with existing equipment and processes, making it easy for manufacturers to upgrade their systems without the need for costly and time-consuming reconfigurations. This is a significant advantage for manufacturers, as it allows them to leverage the latest technology and capabilities without disrupting their ongoing operations. By providing a seamless transition from existing systems to the new product, Processing Pipe is helping manufacturers to maximize the value of their existing investments and stay ahead of the curve in terms of technology and innovation.

With the launch of this new product, Processing Pipe is once again demonstrating its leadership in the manufacturing technology industry. The company has a long history of delivering innovative solutions that help manufacturers to improve their operations, reduce costs, and stay competitive in a fast-paced and ever-changing market. With a focus on continuous improvement and customer satisfaction, Processing Pipe is well-positioned to support manufacturers in addressing their most pressing challenges and achieving their long-term business goals.

In conclusion, the latest product launch from Processing Pipe is a significant development for the manufacturing industry, offering a range of cutting-edge features and capabilities that have the potential to transform the way processing systems are designed and implemented. With its advanced automation capabilities, enhanced data analytics, and seamless integration with existing equipment and processes, this new product has the potential to help manufacturers improve their efficiency, reliability, and overall performance. As a leading provider of advanced technology solutions for the manufacturing industry, Processing Pipe continues to demonstrate its commitment to driving innovation and efficiency in the sector, and this latest product launch is further evidence of their dedication to meeting the evolving needs of their customers.

Company News & Blog

Types of Welding Machines: Applications and Functions

: What They Are and How They Work.Welding machines are a vital tool in the metalworking industry. They work by applying heat to a metal surface until it melts and joins with another piece of metal. There are many different types of welding machines, each suited to specific tasks and materials. However, one type of welding machine that stands out is the easy welding machine.The easy welding machine is a compact, lightweight device that is ideal for small to medium welding projects. It is designed for DIY enthusiasts and beginners who want a straightforward and easy-to-use machine. It is also an excellent choice for those who need to do occasional repairs at home or in a workshop.One of the significant advantages of the easy welding machine is that it is easy to set up and use. Unlike more complicated machines that require extensive training and experience to operate, an easy welding machine is straightforward to use. It comes with clear instructions and straightforward controls, making it easy for anyone to start welding in no time.The easy welding machine uses a process called arc welding. This process works by creating an electric arc between the metal being welded and a welding electrode. The heat generated by the arc melts the metal, creating a pool of molten metal. As the metal cools, it solidifies, forming a strong weld joint.One of the key benefits of using an easy welding machine for arc welding is that it is incredibly versatile. It can weld a wide range of materials, including mild steel, stainless steel, and aluminum. This makes it an ideal tool for a wide range of applications, from repairing metal fences and gates to building custom metal structures.Another advantage of the easy welding machine is its portability. It is small and lightweight, making it easy to move around and transport to different locations. This makes it an excellent tool for those who work on the go or need to weld in tight spaces.Finally, the easy welding machine is affordable. It is an excellent tool for those on a budget or those who only need to do occasional welding. Despite its affordability, it is still a high-quality tool that delivers reliable results.In conclusion, an easy welding machine is an excellent tool for those who want to start welding or need to do occasional repairs. It is easy to set up and use, versatile, portable, and affordable. If you're looking for a straightforward and reliable welding machine, consider an easy welding machine.

Advanced Metal Cutting Technology: A Look into the Latest Innovations in Machinery

OEM Metal Cutting Machinery, a leading provider of advanced CNC machining solutions, has recently announced the launch of its latest product offerings. The company, with years of industry experience and innovation, has again proven its expertise in the field by introducing some of the most advanced CNC machines that cater to the modern manufacturing industry.Founded with the vision of providing high quality and innovative metal cutting solutions to customers, OEM Metal Cutting Machinery has carved out its niche in the market with its commitment to excellence. The company prides itself on its ability to build and deliver reliable, advanced, and dynamic CNC machines that match the evolving needs of the industry.With its latest product offerings, the company has reinforced its commitment, bringing in some of the most innovative machines to the market. Speaking about the new product line, a spokesperson for OEM Metal Cutting Machinery said, “We are excited to bring these machines to the market. Our customers demand machines that are efficient, versatile, and able to handle a wide range of tasks, and these machines deliver just that.”The new product line-up brings together state-of-the-art technology and innovative design, enabling users to improve their manufacturing processes and increase productivity. These machines are designed to meet the needs of a variety of industries, including aerospace, automotive, and medical equipment, among others.One of the new products is a 5-axis CNC machine tool that provides an innovative approach to manufacturing. This machine can handle complex part geometries, as well as reduce set-up and lead times. It’s highly suitable for the aerospace and medical industries, where precision and speed are essential requirements.Another product in the new line-up is a CNC lathe that offers enhanced capabilities for achieving precise results. This highly efficient machine provides reduced cycle times, increased accuracy, and high repeatability. It’s designed to handle a variety of materials from aluminum and stainless steel to high-temperature alloys, making it ideal for the automotive and aerospace industries.In addition, the company is also launching a new laser cutting machine that has the ability to cut through a wide range of material thicknesses. This is due to the machine's use of a unique hybrid fiber laser technology that provides excellent cutting results with high quality and precision. The product is ideal for industries that require high-quality cutting, such as the appliance, industrial machinery, and automotive industries.OEM Metal Cutting Machinery's new product line provides a comprehensive range of CNC machining solutions to businesses with unique manufacturing needs. The company’s commitment to innovation and customer satisfaction is evident in these new offerings. Moreover, OEM Metal Cutting Machinery’s machines are known for their high efficiency, reliability, and long service life, delivering great quality and performance in a wide range of applications.Importantly, OEM Metal Cutting Machinery has also built a reputation for providing excellent customer support. The company’s experienced technical and service team is available to help customers with installation, maintenance, and repair. With this commitment to customer service, customers can be confident in the reliability and continued support of their CNC machines.In conclusion, OEM Metal Cutting Machinery's new range of CNC machines provide the latest in advanced technology, precision, and efficiency to companies in various industries. The company's dedication to innovation and customer satisfaction is reflected in these new product offerings - an outstanding example of its OEM digital power.

Efficient Factory for Blade Cleaning: Revolutionizing the Industry

Blade Cleaner Factory, a leading manufacturer in the cleaning industry, has announced its plans to revolutionize the way blades are cleaned with its innovative solution. Leveraging years of expertise and technological advancements, the company aims to provide efficient, safe, and environmentally friendly cleaning methods for various industries.With a commitment to surpassing customer expectations, Blade Cleaner Factory offers a diverse range of cleaning solutions tailored to specific industries' needs. From the food and beverage sector to medical and surgical instruments, the company ensures superior cleaning results in a cost-effective manner.Blade Cleaner Factory's state-of-the-art machinery and equipment guarantee the removal of contaminants, residue, and debris from blades, improving efficiency and extending lifespan. By incorporating cutting-edge technology, such as ultrasonic cleaning and high-pressure water jets, their solutions deliver optimum cleanliness while preventing any damage to the blades.The company's core values of innovation, quality, and sustainability shine through in its commitment to reducing environmental impact. Blade Cleaner Factory utilizes eco-friendly cleaning agents and techniques that comply with stringent regulations while delivering exceptional results. Customers can rely on the company's expertise to not only achieve cleanliness standards but also minimize their carbon footprint."We understand the importance of not only providing effective cleaning solutions but also doing so in an environmentally responsible manner," said the company spokesperson. "Our team continuously works on improving our processes and investing in sustainable technologies that align with our commitment to the planet."Blade Cleaner Factory's dedication to customer satisfaction extends beyond the quality of their products. The company offers comprehensive after-sales support and maintenance services to ensure continued efficiency and longevity of their cleaning solutions. A team of highly skilled technicians is available for on-site assistance, maintenance, and training, providing customers with peace of mind and minimizing downtime."Our aim is to establish long-term partnerships with our clients. We believe that by providing reliable products and exceptional support, we can contribute to their success," added the spokesperson. "We go the extra mile to understand our customers' unique requirements and offer customized solutions that address their specific challenges."Blade Cleaner Factory's commitment to excellence has earned them a stellar reputation in the industry. Their client portfolio includes major players in various sectors, including food processing plants, hospitals, and laboratories. The company's dedication to continuous improvement and innovation has set them apart, making them the top choice for blade cleaning solutions.As the cleaning industry continues to evolve, Blade Cleaner Factory remains at the forefront with its cutting-edge technologies and customer-centric approach. With a strong emphasis on sustainability, they are poised to lead the way in providing efficient and environmentally friendly cleaning solutions.About Blade Cleaner Factory:Blade Cleaner Factory is a global manufacturer specializing in innovative blade cleaning solutions. With a focus on quality, reliability, and sustainability, they offer a comprehensive range of cleaning equipment to various industries. Through continuous innovation and unparalleled customer support, Blade Cleaner Factory strives to be the leader in the cleaning industry, setting new standards for efficiency and environmental responsibility.

Upgrade Your CNC Machine with a High-Performance Servo Motor

As the manufacturing industry continues to embrace technological advancements, the use of Computer Numerical Control (CNC) machines has become increasingly popular. CNC machines are essential in creating products that require precision and accuracy for companies that are seeking to achieve high-quality production.A CNC machine is an automated piece of equipment that is used for cutting, drilling, and milling a range of materials such as metal, wood, and plastics. To maintain the level of precision required for the machine to operate successfully, it is vital to have the correct equipment, such as a servo motor.Servo motors are used in a range of automated machinery, including CNC machines, to control the position and speed of the device. The accuracy and responsiveness of servo motors ensure that the various components of the machine perform accurately and consistently, ensuring the production of high-quality products.Many servo motor brands are available in the market, each providing unique features, but one company that stands out from the rest is a leading provider of innovative motion control systems. The company has been in existence for several years, providing cutting-edge solutions for the manufacturing industry.The company's products are designed to boost productivity and efficiency. This is achieved through delivering advanced solutions that cater to the needs of a dynamic and evolving market. While there are numerous brands of servo motors in the market, the company's products stand out due to their quality, reliability, and precision.One of the company's leading products is a high-performance servo motor that has revolutionized the CNC machining industry. With this servo motor, CNC machine owners can enhance the accuracy of their machining operations, which helps them to cut down on waste and save on production time. The servo motor ensures that the machine is always responding to new data points, making it easier to maintain the quality of the production process.The servo motor has a range of functions that make it ideal for CNC machines. For instance, it can provide both speed and torque control, something that is imperative for ensuring the effectiveness of the machine's operations. The servo motor's torque control means that it will not continue to rotate beyond what's necessary, ensuring that the components remain intact, and the machine maintains its longevity.The servo motor's speed control is equally essential, as it allows for dynamic speed changes depending on the machining process's requirements. The servo motor can quickly adjust to any speed requirement essential for maintaining the accuracy of the machining process. This feature is essential, especially when working with materials that require differing speed ranges.In addition to its outstanding performance, the servo motor's design is crucial to its functionality and efficiency. The servo motor is compact and lightweight, with a low moment of inertia, which means that it can operate at high speeds without subjecting the machine's components to undue stress.The company's servo motor is designed to operate efficiently even under extreme conditions such as high temperatures or dirty environments. This translates to a reduction in maintenance and operational costs, making it an economical solution for the manufacturing industry.The servo motor's high degree of accuracy ensures that the CNC machine can produce high-quality products that meet the customers' specifications consistently. This is critical, especially for companies in industries such as automotive, aerospace, and medical equipment, which require strict adherence to quality standards.With the advent of Industry 4.0, the manufacturing industry has seen an increased integration of artificial intelligence and automation. As a result, a shift towards smart manufacturing has emerged, where machines can communicate with each other and make decisions based on data analytics. The servo motor from this leading provider is designed to integrate seamlessly with smart machine technology, ensuring seamless communication and data transfer.In conclusion, the manufacturing industry is evolving, and companies are continually seeking the latest technology to improve their productivity and efficiency. The CNC machine is an essential component of the manufacturing process, and a servo motor plays a crucial role in ensuring its accuracy and precision. The servo motor from this leading provider is a reliable solution designed to cater to today's manufacturing needs, and its superior performance makes it a worthy investment for anyone dealing with CNC machines.

Powerful Laser Cleaning Machines for Rust Removal: Bestsellers of 2021

Top Selling Products 2021 Factory Rust Removal 100W 200W 500W 1000W Laser Cleaning MachineLaser cleaning technology is one of the most efficient and cost-effective ways to remove rust and other contaminants from metals, such as carbon steel, stainless steel, aluminum, and titanium. It uses a high-energy laser beam to vaporize and dislodge the rust particles, leaving behind a clean and smooth surface. Laser cleaning is faster, safer, and more precise than traditional methods, such as sandblasting, chemical cleaning, and mechanical scrubbing. It also produces less waste, noise, and environmental pollution.If you are looking for a reliable and versatile laser cleaning machine for your industrial or commercial applications, you may consider the top-selling products from Dapeng Laser Home, a reputable and experienced manufacturer of laser equipment. They offer a range of laser cleaning machines with different power levels and features, depending on your specific cleaning needs and budget.Here are some of the key features and benefits of their top-selling products:1. Factory Rust Removal 100W Laser Cleaning MachineThis compact and portable laser cleaner is suitable for small to medium-sized metal parts and surfaces, such as gears, bearings, valves, and pipes. It has a laser power of 100 watts and a scanning width of 10 to 110 mm, which can remove rust, oil, paint, and other contaminants at a speed of up to 5 m/s. It also has a built-in air cooling system and a user-friendly interface for easy operation and maintenance. The price of this machine starts from around $10,000, depending on the configuration and accessories.2. Factory Rust Removal 200W Laser Cleaning MachineThis more powerful and versatile laser cleaner is ideal for medium to large-sized metal parts and surfaces, such as steel plates, ship hulls, aircraft components, and molds. It has a laser power of 200 watts and a scanning width of 10 to 150 mm, which can remove rust, oxide, scale, and other stubborn contaminants at a speed of up to 10 m/s. It also has an automatic focusing system and a safety protection system for reliable and efficient cleaning results. The price of this machine starts from around $20,000, depending on the configuration and accessories.3. Factory Rust Removal 500W Laser Cleaning MachineThis high-power and high-performance laser cleaner is suitable for heavy-duty and demanding metal parts and surfaces, such as railway tracks, pipelines, turbines, and heat exchangers. It has a laser power of 500 watts and a scanning width of 10 to 200 mm, which can remove rust, corrosion, welding marks, and other thick or stubborn contaminants at a speed of up to 20 m/s. It also has a wireless remote control and a real-time monitoring system for easy and accurate cleaning operations. The price of this machine starts from around $50,000, depending on the configuration and accessories.4. Factory Rust Removal 1000W Laser Cleaning MachineThis ultra-high-power and top-of-the-line laser cleaner is designed for the most challenging and critical metal parts and surfaces, such as nuclear reactors, aerospace engines, and military weapons. It has a laser power of 1000 watts and a scanning width of 10 to 300 mm, which can remove rust, paint, coatings, and other complex or layered contaminants at a speed of up to 30 m/s. It also has an intelligent image recognition system and a dust-free enclosure for maximum precision and cleanliness. The price of this machine starts from around $100,000, depending on the configuration and accessories.In summary, if you want to improve your metal cleaning efficiency, quality, and safety, you may consider investing in a laser cleaning machine from Dapeng Laser Home. Their top-selling products offer various power levels, scanning widths, features, and prices for your different needs and preferences. To get the best laser cleaner 1000w price, you may consult their sales team or visit their website for more information and quotes. With their reliable and innovative laser cleaning technology, you can achieve a better and brighter metal surface for your business success.

Top 10 Affordable CO2 Laser Cutting Machines for Sale

Title: Promising CO2 Laser Cutting Machine Unveiled by Cutting-Edge CompanyIntroduction:In a significant development for the manufacturing industry, a leading company has recently launched an advanced CO2 laser cutting machine. This innovative piece of equipment, designed to provide precise and efficient cutting solutions, promises to revolutionize the manufacturing processes across various industries. With its cutting-edge technology and unparalleled performance, this machine offers immense potential for enhancing productivity, reducing costs, and ensuring higher quality outputs. Let us delve into the features and advantages of this remarkable CO2 laser cutting machine.1. Unmatched Precision:The newly unveiled CO2 laser cutting machine is equipped with state-of-the-art technology that guarantees exceptional precision. Its high-powered laser beam, meticulously guided by advanced computer-controlled systems, ensures accurate cutting, even for the most intricate and complex designs. This level of precision eliminates the need for additional finishing processes, saving both time and resources for manufacturers.2. Versatile and Wide-ranging Capabilities:With its versatility and wide-ranging capabilities, this CO2 laser cutting machine caters to diverse applications across multiple industries. From metal fabrication to textile production and signage making, this machine can effortlessly handle a vast array of materials including stainless steel, carbon steel, acrylic, wood, and more. Moreover, it can accommodate varying thicknesses, making it suitable for small-scale manufacturers as well as large-scale production units.3. Increased Productivity and Efficiency:By implementing this CO2 laser cutting machine, manufacturing companies can significantly boost productivity and efficiency. The machine's high cutting speed ensures faster turnaround times, enabling manufacturers to meet strict deadlines. Additionally, its automated processes minimize human error and reduce the reliance on manual labor, thereby streamlining operations and reducing production costs.4. Enhanced Safety Features:Safety features have been given utmost importance while developing this CO2 laser cutting machine. The enclosed cutting zone prevents harmful fumes and dust from spreading, ensuring a safe working environment. Additionally, the machine is equipped with advanced sensors that detect any anomalies, automatically halting the cutting process to avoid accidents. These safety measures not only protect the operators but also safeguard the integrity of the manufactured goods.5. User-friendly Interface:The CO2 laser cutting machine offers an intuitive user interface that enables easy operation for both seasoned professionals and novices. Its user-friendly control panel allows operators to adjust cutting parameters and monitor the progress of the job with ease. The machine also supports various file formats, enabling seamless integration with existing design software to simplify the production workflow.Conclusion:The advent of this cutting-edge CO2 laser cutting machine presents an exciting opportunity for manufacturers to transform their production processes. With its unparalleled precision, versatile capabilities, and user-friendly interface, this machine holds immense potential to enhance productivity, ensure higher quality outputs, and reduce manufacturing costs. As industries continue to evolve, this innovative technology is poised to play a pivotal role in revolutionizing manufacturing operations. Manufacturers and businesses alike can leverage this cutting-edge equipment to gain a competitive edge in their respective fields.

The Cost of Fiber Laser Cutting Head: What You Need to Know

Title: Fiber Laser Cutting Head Market Witnessing Significant Growth with Technological AdvancementsIntroduction:The global market for fiber laser cutting heads is witnessing significant growth as industrial manufacturers increasingly adopt advanced laser technologies for precision cutting applications. Fiber laser cutting heads are crucial components in laser cutting systems, enabling efficient cutting of materials with high precision and accuracy. This article aims to explore the current market landscape, technological advancements, and factors driving the growth of fiber laser cutting head market.Market Overview:The fiber laser cutting head market has been experiencing robust growth in recent years, driven by the rising demand for high-quality laser cutting systems across various industries. Fiber lasers offer several advantages over traditional CO2 lasers, including higher efficiency, faster cutting speeds, lower operational costs, and greater reliability. Consequently, industrial manufacturers are increasingly replacing their existing CO2 lasers with fiber lasers, contributing to the surging demand for fiber laser cutting heads.Moreover, the growing adoption of automation and Industry 4.0 practices further fuels the demand for fiber laser cutting heads. These heads are essential components in automated laser cutting systems, allowing precision cutting of various materials such as metal, plastic, and wood. The ability to seamlessly integrate fiber laser cutting heads with automated manufacturing processes enhances productivity, reduces labor costs, and ensures consistent quality output.Technological Advancements:Fiber laser cutting head manufacturers are continuously investing in research and development to introduce innovative technologies that improve cutting precision and efficiency. These advancements have led to the emergence of high-performance, intelligent cutting heads equipped with features like automatic focusing, real-time monitoring, and adaptive control mechanisms.One notable technological advancement in fiber laser cutting heads is the integration of sensors and cameras. These cutting heads utilize advanced vision systems to detect and adapt to variations in material thickness, enabling precise cuts regardless of fluctuations. This technology not only enhances cutting accuracy but also minimizes material waste and reduces production time.Additionally, the introduction of fiber-disk technology has revolutionized the market. Fiber-disk cutting heads offer improved power stability and beam quality, resulting in superior cutting performance across various materials. The ability to switch between different output powers provides operators with flexibility and versatility, making fiber-disk cutting heads a popular choice for industrial manufacturers.Market Players:Several prominent companies are actively involved in the fiber laser cutting head market. These companies compete based on product quality, technological innovations, and competitive pricing strategies.Conclusion:The global fiber laser cutting head market is experiencing robust growth owing to the increasing adoption of fiber laser cutting systems across various industries. Technological advancements, such as the integration of sensors and cameras, the emergence of fiber-disk technology, and the focus on automation, are driving the market's growth. As the demand for high-precision cutting solutions continues to rise, manufacturers will further invest in research and development to develop cutting-edge fiber laser cutting heads, catering to the evolving needs of industrial manufacturers.

Essential Guide to Welding Equipment: How to Choose the Right Tools for Optimal Results

Title: Innovations in Welding Equipment Revolutionize the Manufacturing IndustryIntroduction:In an era characterized by fast-paced technological advancements, the manufacturing industry is constantly seeking innovative solutions that enhance efficiency and productivity. Welding, a fundamental process in the industry, plays a crucial role in the assembly and fabrication of various products. Recognizing the need for advanced welding equipment, the renowned manufacturing company has introduced a groundbreaking range of solutions that are set to revolutionize the welding industry. Through cutting-edge research and development, this company has successfully designed equipment that caters to the evolving needs of modern manufacturing processes.Paragraph 1:With a rich history of delivering high-quality products, the manufacturing company has established itself as a leading player in the industry. Leveraging their expertise and state-of-the-art facilities, they have developed a new series of welding equipment that incorporates technological advancements. By addressing the shortcomings of traditional welding machines, this latest range offers unprecedented precision, performance, and safety measures for welders and manufacturing professionals.Paragraph 2:One of the notable features of this advanced welding equipment is its enhanced automation capabilities. By leveraging robotics and artificial intelligence, the equipment streamlines the welding process, reducing the possibility of human error and ensuring consistent weld quality. The integration of automated controls also improves worker safety by minimizing their exposure to hazardous welding conditions, such as high temperatures and toxic fumes.Paragraph 3:Furthermore, the equipment boasts improved connectivity and data analysis capabilities, allowing manufacturers to gather real-time performance data and monitor welding operations remotely. This information can be utilized to optimize welding processes, enhance productivity, and reduce downtime. Additionally, the equipment supports predictive maintenance, enabling proactive identification and prevention of potential equipment failures, thus minimizing costly repairs and production interruptions.Paragraph 4:In response to the growing demand for sustainable manufacturing practices, the company has incorporated eco-friendly features into the welding equipment. By utilizing energy-efficient technologies and reducing harmful emissions, these machines not only contribute to a greener environment but also help manufacturers adhere to stringent environmental regulations.Paragraph 5:As the manufacturing industry becomes increasingly globalized, the company has also emphasized user-friendly design in their new welding equipment. This ensures that welders, regardless of their skill levels, can easily operate and maintain these machines. Clear and intuitive interfaces, along with comprehensive user manuals, have been developed to ensure a seamless transition for manufacturers.Paragraph 6:To ensure that the welding equipment meets the specific needs of industries, the company has collaborated with key manufacturers, experts, and industry leaders. This collaborative approach has allowed for a thorough understanding of industry requirements, resulting in tailor-made solutions that address challenges and contribute to the manufacturing industry's overall growth.Conclusion:With the introduction of their innovative welding equipment, the manufacturing company has reinforced its commitment to shaping the future of the industry. By combining cutting-edge technology with user-friendly features, this range of equipment aims to enhance productivity, efficiency, and safety standards in welding processes. As the manufacturing industry continues to evolve, the ongoing dedication to research and development by companies like this serves as a driving force, paving the way for more advanced and sustainable manufacturing practices.

Top Portable Laser Welder for Efficient Welding

Portable Laser Welder Revolutionizes On-the-Go WeldingIn today's fast-paced world, industries are constantly seeking new and innovative ways to improve efficiency and productivity. The manufacturing and repair industries, in particular, are always on the lookout for advanced technologies that can help them save time and money while maintaining high-quality standards.One company at the forefront of this technological revolution is {company name}. With a strong commitment to research and development, the company has recently introduced a game-changing product that is set to revolutionize on-the-go welding: the Portable Laser Welder.Traditionally, welding has been a time-consuming and labor-intensive process, requiring bulky and stationary equipment. However, with the Portable Laser Welder, welders now have the ability to perform precise and high-quality welding operations in remote locations, on construction sites, and even in the field.The Portable Laser Welder is designed to be compact and lightweight, making it easy to transport to any job site. Its portability, combined with its advanced laser technology, allows for quick and efficient welding without compromising on the quality of the weld.One of the key features of the Portable Laser Welder is its versatility. It can be used for a wide range of materials, including steel, aluminum, and even some non-metallic materials. This makes it an ideal tool for various industries, from automotive and aerospace to construction and shipbuilding.The precision and accuracy of the Portable Laser Welder are also unparalleled. Its advanced laser technology allows for pinpoint accuracy, resulting in clean and flawless welds. This level of precision is especially crucial in industries where the quality of the weld is essential for the safety and integrity of the finished product.Furthermore, the Portable Laser Welder is designed for user-friendly operation. With its intuitive interface and easy-to-use controls, even inexperienced welders can quickly learn to use the device. This not only saves time on training but also ensures consistent and high-quality results.In terms of safety, the Portable Laser Welder exceeds industry standards. It is equipped with advanced safety features to protect the user from potential hazards associated with welding. This includes protective shielding, automatic shut-off mechanisms, and built-in safety protocols.{company name} has also made a strong commitment to providing comprehensive training and support for customers who invest in the Portable Laser Welder. This includes on-site training, technical support, and access to a team of experts who can provide guidance and assistance as needed.The impact of the Portable Laser Welder on the welding industry is already being felt. Not only has it improved the efficiency of on-the-go welding operations, but it has also opened up new opportunities for businesses to take on projects that were previously deemed impractical due to the limitations of traditional welding equipment.With its high-quality and precise welding capabilities, combined with its portability and user-friendly design, the Portable Laser Welder has set a new standard for on-the-go welding. It is a testament to {company name}'s commitment to pushing the boundaries of technological innovation and providing practical solutions for the modern industry.As the demand for efficient and high-quality welding solutions continues to grow, the Portable Laser Welder is poised to play a crucial role in meeting the needs of industries worldwide. It represents a significant advancement in welding technology and is set to further revolutionize the way welding operations are conducted, both in the workshop and out in the field.

Tools and Accessories for Welding Machines and Upgrades

article about the benefits of investing in high-quality welding machines and accessories.Welding machines and accessories are at the core of any welding operation, and investing in high-quality equipment is essential for achieving precise, consistent, and high-quality welds. As the demand for welding services continues to increase in various industries, companies that prioritize the quality of their equipment can improve their productivity, efficiency, and profitability. This is where Arc-Zone.com, a leading welding accessories store, comes in, providing a wide range of welding machines and tools that meet the diverse needs of welders.Arc-Zone.com has become a trusted partner for welders of all skill levels, providing comprehensive solutions for welding tools and accessories both online and offline. The company has established a reputation for offering reliable and high-performance welding machines, from TIG and MIG welders to plasma cutting systems, along with all the necessary accessories to make welding processes more manageable. The elevated level of craftsmanship in each of these machines is what sets them apart from cheaper counterparts.The higher price of high-quality welding machines and accessories may seem prohibitive to some, but in reality, they offer numerous benefits that justify their value. For starters, investing in these machines reduces the risk of frequent repairs and replacements, which translates to cost savings in the long run. In addition, high-quality machines are designed to deliver high levels of efficiency and productivity, reducing production times and increasing output. This is particularly useful in commercial settings, where welding operations are time-bound.Another benefit of investing in high-quality welding machines and accessories is the improvement in the quality of welds. Precision is a hallmark feature of these machines, which ensures that welds are consistent, strong, and visually appealing. This can greatly enhance the overall quality of products that require welding, improving their durability and reliability. High-quality welding machines and accessories can also help reduce the likelihood of safety hazards in the workplace, as they are designed to operate safely, reducing risks such as electric shock, burns, and eye damage to the welder.Arc-Zone.com's product offerings meet the needs of both novice and professional welders. The company's wide range of welding machines includes reliable TIG welders, precise MIG welders, and efficient plasma cutters, each designed with the specific requirements of each process in mind. The machines come in different sizes and capabilities, allowing welders to choose a fitting machine that can deliver the desired results. The company also offers a selection of accessories to go with each machine, such as connectors, reels, and adapters, as well as gas purging equipment and remote amperage controls.The superiority of Arc-Zone.com's welding machines and accessories lies in the attention to detail and the use of high-quality components and materials. These machines are built to withstand the rigors of demanding welding environments, maintain their accuracy, and durability even after prolonged use. The company also employs continuous research and development in the manufacture of its products, ensuring that withstands future demands and applications in the industry.In conclusion, investing in high-quality welding machines and accessories such as those offered by Arc-Zone.com is necessary for any welding operation. The benefits of precision, efficiency, increased output, and safety, among others, justify the higher costs associated with these machines. With a wide range of machines and accessories designed to meet the needs of both novice and professional welders, Arc-Zone.com is a reliable provider of high-quality welding products. Welders using their products can be confident in achieving high-quality welds, increased productivity, and reduced repair costs.