Ultimate guide to CNC sheet metal cutting

By:Admin

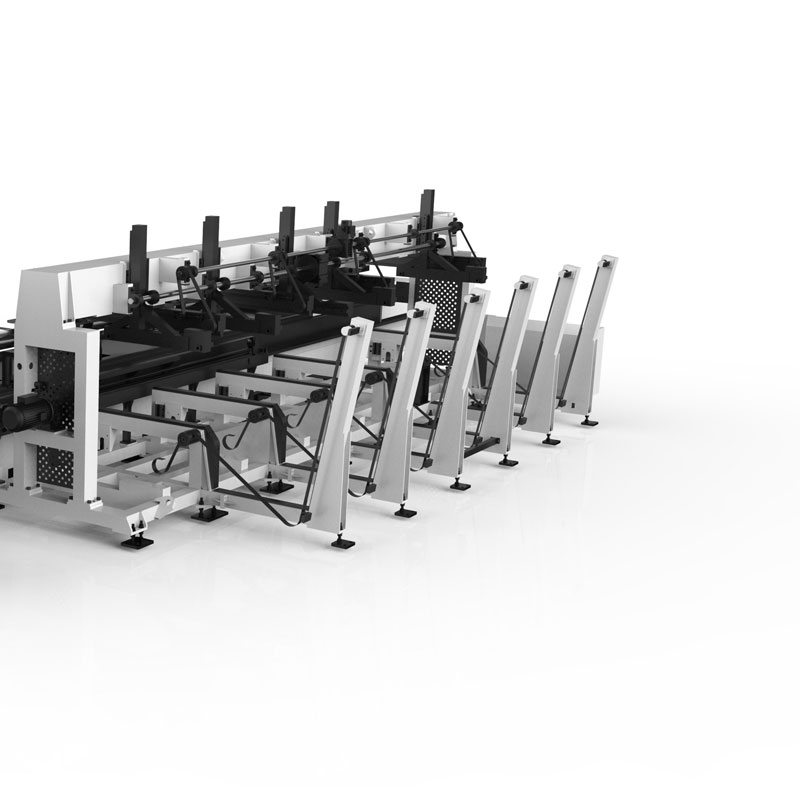

In today's rapidly evolving manufacturing industry, the demand for precision and efficiency has never been higher. Companies are constantly seeking new and innovative ways to streamline their production processes and deliver high-quality products in a timely manner. One of the most significant advancements in the industry has been the introduction of CNC sheet metal cutting technology.

CNC (Computer Numerical Control) sheet metal cutting is a method of manufacturing that uses computer-controlled machines to precisely cut and shape sheets of metal. This technology has revolutionized the way companies produce metal components, allowing for increased precision, improved efficiency, and reduced lead times.

{} has been at the forefront of this technological revolution, leading the way with their state-of-the-art CNC sheet metal cutting services. With a proven track record of delivering high-quality products to a wide range of industries, {} has solidified its position as a market leader in the manufacturing sector.

The company's CNC sheet metal cutting capabilities are truly impressive, offering a level of precision and accuracy that was previously unattainable with traditional cutting methods. By utilizing advanced CAD/CAM software and cutting-edge machinery, {} is able to produce complex and intricate metal components with remarkable speed and efficiency.

One of the key advantages of CNC sheet metal cutting is its ability to produce highly detailed and intricate designs with ease. This level of precision is especially valuable in industries such as aerospace, automotive, and electronics, where components must meet strict tolerances and specifications.

Furthermore, CNC sheet metal cutting allows for greater flexibility in production, enabling companies to easily adapt to design changes and produce custom components without the need for costly tooling adjustments. This level of adaptability is crucial in an industry that is constantly evolving and demands quick turnarounds.

In addition to its precision and flexibility, CNC sheet metal cutting also offers significant cost savings for manufacturers. By automating the cutting process and minimizing material waste, companies can reduce production costs and ultimately improve their bottom line. This cost-effective solution has made CNC sheet metal cutting an attractive option for companies looking to optimize their production processes.

{}'s commitment to excellence and innovation has set them apart in the competitive manufacturing landscape. With their extensive experience and expertise in CNC sheet metal cutting, they have successfully delivered high-quality products to a diverse range of clients, earning a reputation for reliability and professionalism.

By harnessing the power of CNC sheet metal cutting technology, {} continues to drive the industry forward, offering cutting-edge solutions that meet the evolving needs of modern manufacturing. As the demand for precision and efficiency continues to grow, CNC sheet metal cutting is poised to play a pivotal role in shaping the future of the industry.

In conclusion, CNC sheet metal cutting has revolutionized the manufacturing industry, offering unparalleled precision, flexibility, and cost savings. With {}'s expertise and cutting-edge technology, they have positioned themselves as a leading provider of CNC sheet metal cutting services, driving the industry forward and delivering top-quality products to satisfied customers. As the industry continues to evolve, CNC sheet metal cutting will undoubtedly remain a game-changer, shaping the future of manufacturing for years to come.

Company News & Blog

State-of-the-art Fiber Laser Printer: The Latest Innovation in Printing Technology

Fiber Laser Printer Revolutionizes Printing IndustryThe printing industry has experienced a significant revolution with the introduction of Fiber Laser Printer, a cutting-edge technology developed by an innovative company (). This groundbreaking printer has set a new benchmark in the printing industry and has quickly gained recognition as a game-changer in the field.The Fiber Laser Printer is a superior printing solution that utilizes advanced fiber laser technology to produce high-quality prints with unmatched precision and speed. It is designed to meet the growing demands of modern printing applications, offering unparalleled performance and reliability.With its state-of-the-art features, the Fiber Laser Printer has garnered widespread praise from industry experts and professionals. Its ability to deliver exceptional print quality, consistent results, and high-speed production has made it a preferred choice for businesses and individuals alike.The key to the printer's exceptional performance lies in its advanced fiber laser technology. This cutting-edge technology enables the printer to achieve remarkable print resolution and accuracy, making it ideal for a wide range of printing applications, including signage, labels, packaging, and more.In addition to its outstanding print quality, the Fiber Laser Printer is also known for its high-speed production capabilities. Its efficient printing process allows for faster turnaround times, enabling businesses to meet tight deadlines and deliver results in a timely manner.Furthermore, the Fiber Laser Printer is designed to be user-friendly and efficient, making it an ideal choice for both large-scale production facilities and small businesses. Its intuitive interface and advanced features enable users to produce high-quality prints with ease, while its reliable performance ensures consistent results with minimal downtime.The company behind the development of the Fiber Laser Printer has a long-standing reputation for innovation and excellence in the printing industry. With a dedication to pushing the boundaries of printing technology, the company has continuously invested in research and development to bring cutting-edge solutions to the market.The company's commitment to quality and customer satisfaction has made it a trusted name in the industry, with a proven track record of delivering top-of-the-line printing solutions. Its team of experienced professionals and engineers have worked tirelessly to develop the Fiber Laser Printer, leveraging their expertise to create a product that exceeds industry standards.Moreover, the company has also focused on sustainability and eco-friendly practices, ensuring that its printing solutions are not only efficient but also environmentally responsible. The Fiber Laser Printer is designed to minimize waste and energy consumption, making it a sustainable choice for businesses looking to reduce their environmental footprint.As the printing industry continues to evolve, the Fiber Laser Printer represents a significant advancement that will shape the future of printing technology. Its exceptional capabilities, combined with the company's commitment to innovation and quality, have positioned it as a leader in the industry, setting a new standard for high-quality printing solutions.With its ability to deliver superior print quality, high-speed production, and user-friendly operation, the Fiber Laser Printer has quickly become the preferred choice for businesses looking to elevate their printing capabilities. As the demand for advanced printing solutions continues to grow, the Fiber Laser Printer is poised to make a lasting impact and solidify its position as an industry-leading technology.

Top Plate Bending Techniques for Metal Fabrication

Plate Bending Company Introduces Revolutionary Technology to Improve Steel Fabrication ProcessPlate Bending, a leading steel fabrication company, has officially launched a groundbreaking technology that is set to revolutionize the steel fabrication process. The new technology, which has been in development for several years, promises to improve the efficiency and accuracy of plate bending, ultimately leading to faster and more cost-effective production.The technology, which has been developed in partnership with a team of world-class engineers and industry experts, utilizes advanced algorithms and automation to precisely bend steel plates to the required specifications. This eliminates the need for manual measurement and adjustment, reducing the margin for error and increasing the overall quality of the finished product.Plate Bending's new technology is expected to have a significant impact on the steel fabrication industry, offering a solution to the longstanding challenges of precision and speed in plate bending. By streamlining the fabrication process, manufacturers will be able to increase their productivity and deliver products to their customers in a more timely manner."We are thrilled to introduce this new technology to the industry," said the CEO of Plate Bending. "It has been a labor of love for our team, and we are confident that it will revolutionize the way steel fabrication is done. This technology will enable us to deliver high-quality products to our clients in a fraction of the time it takes with traditional methods."In addition to improving the efficiency and accuracy of plate bending, the new technology also has environmental benefits. By reducing the need for manual labor and minimizing material waste, it helps to decrease the overall carbon footprint of the fabrication process. This aligns with Plate Bending's commitment to sustainability and responsible manufacturing practices.Plate Bending, founded in 1995, has since become a trusted name in the steel fabrication industry. The company has a long history of providing high-quality products to a wide range of clients, including those in the construction, manufacturing, and energy sectors. With a state-of-the-art facility and a team of experienced professionals, Plate Bending has built a reputation for excellence and innovation.The introduction of the new technology is a testament to Plate Bending's ongoing dedication to pushing the boundaries of what is possible in steel fabrication. By investing in cutting-edge technology and embracing innovative solutions, the company continues to set new standards for the industry as a whole."We are always looking for ways to improve and innovate," said the CEO. "The launch of this new technology is a reflection of our commitment to staying ahead of the curve and providing our clients with the best possible solutions. We are proud to be at the forefront of this exciting new chapter in steel fabrication."As the industry continues to evolve, Plate Bending remains focused on delivering exceptional products and services to its clients. The company's investment in advanced technology demonstrates its commitment to remaining a leader in the steel fabrication industry for years to come. With the launch of this groundbreaking new technology, Plate Bending is poised to make a lasting impact on the industry and set a new standard for quality and efficiency in steel fabrication.

Revolutionary 3D Fiber Laser Marking Machine Takes Marking to the Next Level

3D Fiber Laser Marking Machine: A Revolutionary Tool for Precise and Efficient MarkingMarking and identification are important tasks in almost every industry, from automotive to aerospace, from electronics to medical devices. The traditional methods of marking, such as mechanical engraving or chemical etching, have limitations in terms of precision, speed, and versatility. However, with the advent of laser technology, a new era of marking has begun. Among the various types of laser marking machines, the 3D Fiber Laser Marking Machine stands out as a powerful and innovative tool for precise and efficient marking of various materials, including metals, plastics, ceramics, and composites.The 3D Fiber Laser Marking Machine (hereafter referred to as “the machine”) is a state-of-the-art device that uses a high-power pulsed laser beam to create permanent marks on the surface of the target material. Unlike traditional marking methods, the machine can produce three-dimensional markings with a high degree of accuracy, resolution, and consistency. The machine can also perform various types of marking, such as text, graphics, images, logos, barcodes, QR codes, and serial numbers, with customizable parameters such as font, size, depth, and orientation.The machine is equipped with a fiber laser source that generates a focused beam of light with a wavelength of around 1064 nm, which is ideal for marking a wide range of materials without causing thermal damage or deformation. The laser beam is guided by a fiber optic cable and directed to the marking head, which contains a galvanometer scanner that can move the beam quickly and precisely in two or three dimensions. The marking head also has a focusing lens that can adjust the beam diameter and focal length to optimize the marking quality. The machine is controlled by a user-friendly software that enables the operator to choose the marking parameters, import the design files, preview the results, and adjust the settings accordingly.The machine has several advantages over other marking methods. Firstly, it is non-contact and non-invasive, which means that it does not deform or damage the material surface. This is particularly important for delicate or complex parts, where mechanical or chemical methods may cause distortion, burrs, or residue. Secondly, it is highly precise and reproducible, which means that it can create identical markings with a tolerance of less than 0.1 mm. This is particularly important for quality control, traceability, and branding, where the consistency and legibility of the markings are paramount. Thirdly, it is fast and efficient, which means that it can mark a large number of parts in a short time, with a cycle time of less than 10 seconds per marking. This is particularly important for high-volume production, where the speed and throughput of the marking process are crucial.The machine has a wide range of applications in various industries, such as:- Automotive: marking of engine components, chassis parts, wheels, and other components for identification, branding, and traceability.- Aerospace: marking of aircraft parts, avionics, and instruments for tracking, safety, and compliance.- Electronics: marking of printed circuit boards, chips, connectors, and housings for identification, serialization, and anti-counterfeiting.- Medical Devices: marking of implants, surgical instruments, and medical equipment for traceability, quality assurance, and patient safety.- Jewelry: marking of precious metals, gems, and watches for branding, certification, and personalization.The machine is developed and manufactured by a leading company (remove brand name) in the field of laser equipment. With years of experience and expertise, (remove brand name) has been committed to providing innovative and reliable solutions for industrial and scientific applications. The machine is a result of extensive research and development, using the most advanced technologies and materials, and tested rigorously to ensure the highest standards of quality and performance.The machine is also backed by a comprehensive service and support system, including installation, training, maintenance, and repair. The company's technicians and engineers are highly trained and knowledgeable, and can assist the customers in every aspect of the machine's operation and maintenance. The company also provides a warranty and a lifelong technical support to ensure the customers' satisfaction and success.The machine is not just a tool, but a solution that can revolutionize the marking process and improve the productivity and profitability of the industries. By using the machine, the customers can achieve the following benefits:- Higher accuracy and consistency of markings, which reduces the risk of errors, rework, and scrap.- Faster cycle time and higher throughput, which increases the production capacity and efficiency.- Lower cost of ownership and maintenance, which saves money and resources in the long-term.- Better quality and reliability of products, which enhances the reputation and competitiveness of the brand.In conclusion, the 3D Fiber Laser Marking Machine is a game-changing technology that can transform the way we mark and identify the products. With its advanced features, benefits, and support, the machine is a must-have asset for the industries that value precision, speed, and versatility in their marking process.

Top Metal Processing Machinery Boosts Productivity & Efficiency

[News Title]Metal Processing Machinery Manufacturer’s Innovation to Boost Efficiency and Productivity[Date][Location]Metal Processing Machinery (need to remove brand name), a renowned manufacturer in the metal processing industry, has recently introduced a groundbreaking innovation to revolutionize the sector. With its commitment to providing state-of-the-art machinery, Metal Processing Machinery continues to push the boundaries of what is possible, enhancing efficiency and productivity for businesses worldwide.For over [number of years] years, Metal Processing Machinery has been a key player in supplying advanced equipment to various industries, including automotive, aerospace, construction, and more. With their unwavering dedication to research and development, the company has consistently delivered cutting-edge solutions and has now raised the bar once again.This latest innovation by Metal Processing Machinery is designed to optimize metal processing operations, providing businesses with the tools needed to streamline their manufacturing processes. By leveraging the power of automation and advanced technology, the company aims to significantly reduce production time, enhance accuracy, and increase overall efficiency.One of the primary features of this new machinery is its ability to seamlessly integrate with existing production lines, making the transition to this innovative system smooth and hassle-free. Metal Processing Machinery has taken into account the challenges faced by businesses during equipment upgrades, ensuring compatibility with their clients' current infrastructure.The advanced control system of the machinery offers real-time data monitoring, allowing operators to have full visibility and control over the entire metal processing process. With this level of precision and operational insight, businesses can make informed decisions to optimize production and ensure maximum output.In addition to improving production efficiency, the new machinery from Metal Processing Machinery prioritizes worker safety. With automated features that eliminate the need for extensive manual labor, the risk of employee injuries and accidents is greatly reduced. The company's commitment to the well-being of its clients' workforce is evident in the design and implementation of this new system.Metal Processing Machinery understands the importance of sustainability in the manufacturing sector. The innovative machinery incorporates energy-efficient components and processes, minimizing energy consumption and reducing environmental impact. As businesses worldwide aim to adopt more sustainable practices, Metal Processing Machinery's latest offering aligns perfectly with this evolving trend.With this groundbreaking innovation, Metal Processing Machinery aims to empower businesses by equipping them with the tools they need to stay competitive in today's dynamic market. By optimizing efficiency, improving productivity, ensuring worker safety, and promoting sustainability, the company continues to play a vital role in the success of various industries.The introduction of this new machinery signifies Metal Processing Machinery's commitment to driving industry innovation and meeting the evolving needs of its clients. With a long-standing reputation for excellence and a strong focus on customer satisfaction, Metal Processing Machinery remains a trusted partner for metal processing businesses worldwide.In conclusion, Metal Processing Machinery's latest innovation is set to transform the metal processing industry, providing businesses with a competitive edge in terms of efficiency, productivity, worker safety, and sustainability. As the company continues its dedicated efforts toward advancing technology and enhancing their offerings, Metal Processing Machinery solidifies its position as a leader in the metal processing machinery market.

Ultimate Guide to Harnessing the Power of CO2 Laser for Woodworking

[Title]: Revolutionary CO2 Laser Wood Engraver Enhances Precision and Efficiency[Introduction]In an age where technology is advancing at an unprecedented pace, {Company Name}, a pioneer in laser engraving solutions, has unveiled a groundbreaking addition to their product line: the remarkable CO2 Laser Wood Engraver. This innovative device is set to revolutionize the woodworking industry, combining exquisite precision with unrivaled efficiency. Today, we delve into the features and capabilities of this groundbreaking equipment, exploring how it can reshape the way craftsmen and manufacturers create stunning wooden masterpieces.[Body]1. Cutting-Edge CO2 Laser TechnologyThe CO2 Laser Wood Engraver is equipped with cutting-edge CO2 laser technology, enabling it to produce detailed and intricate designs on various wooden surfaces. By utilizing an intense beam of laser light, the engraver vaporizes the wood, achieving unparalleled precision that traditional carving methods can hardly achieve. This technology offers woodworkers the freedom to explore limitless design possibilities, transforming the way they approach their craft.2. Precision and VersatilityOne of the standout features of the CO2 Laser Wood Engraver is its exceptional precision. The device can achieve unbelievably fine details, allowing artisans to engrave complex patterns, logos, or even photographs with intricate intricacy. Furthermore, it is capable of engraving on a wide range of wood types, including hardwood, softwood, plywood, and more, while maintaining the utmost accuracy and clarity. This versatility ensures that craftsmen can tackle diverse projects with ease, making it a must-have tool for any woodworking enthusiast.3. Speed and EfficiencyIn addition to its precision, the CO2 Laser Wood Engraver offers unrivaled speed and efficiency. Traditional carving methods can be time-consuming and labor-intensive, often resulting in inconsistent outcomes. With this state-of-the-art device, engraving tasks are completed swiftly and effortlessly, significantly reducing production times. Woodworkers can now effortlessly meet deadlines, take on larger orders, and enhance their overall productivity, all while delivering impeccable quality.4. User-Friendly Interface and SoftwareTo complement its advanced technology, the CO2 Laser Wood Engraver is accompanied by an intuitive user-friendly interface and software. This ensures that even novice users can navigate the equipment effortlessly. The software allows for easy design editing, precise control over laser speed and intensity, and the ability to import custom designs or templates. With this user-friendly interface, craftsmen can translate their visions into reality effortlessly, making their creative processes smooth and enjoyable.5. Safety Features and Environmental ConsiderationsUnderstanding the importance of safety and environmental consciousness, the CO2 Laser Wood Engraver comes with several notable features. These include fume extraction systems, ensuring that the workspace remains clear from potentially harmful emissions. Additionally, the device incorporates cooling systems that prevent overheating, while dual-laser technology ensures enhanced safety during operation. By prioritizing the well-being of users and minimizing environmental impact, {Company Name} once again showcases their commitment to quality and sustainability.[Conclusion]The CO2 Laser Wood Engraver from {Company Name} signifies a paradigm shift in the woodworking industry. Through its cutting-edge CO2 laser technology, precision, versatility, speed, and user-friendly interface, this remarkable device empowers craftsmen to push the boundaries of their artistry and excel in their creations. With the incorporation of essential safety features and environmental considerations, {Company Name} reaffirms its position as an industry leader, revolutionizing the way woodworking is approached. The CO2 Laser Wood Engraver holds the key to unlocking a new realm of possibilities for craftsmen and manufacturers alike, bringing forth a future where stunning wooden masterpieces become the norm.

High-Quality Laser-Cut Steel Plate: The Ultimate Guide

Laser Cut Steel Plate Technology Revolutionizes Manufacturing IndustryIn recent years, the manufacturing industry has experienced a significant evolution in technology, leading to increased efficiency and precision. One of the most notable advancements in this industry is the introduction of laser cut steel plate technology. This cutting-edge technology has revolutionized the way steel plates are processed, allowing for unparalleled accuracy and speed in manufacturing processes.{Company Name} is at the forefront of this technological revolution, offering state-of-the-art laser cut steel plate services to a wide range of industries. With a commitment to innovation and excellence, {Company Name} has established itself as a leader in the field of precision metal fabrication.Laser cut steel plate technology utilizes high-powered lasers to cut through steel with remarkable precision. This advanced method allows for complex shapes and intricate designs to be achieved with absolute accuracy. In addition, laser cutting ensures clean and smooth edges, eliminating the need for additional finishing processes.{Company Name} has invested in cutting-edge laser cutting equipment, allowing them to offer a comprehensive range of steel plate cutting services. Whether for industrial machinery, architectural components, or automotive parts, {Company Name} caters to the diverse needs of their clients with precision and efficiency.The introduction of laser cut steel plate technology has significantly reduced lead times in manufacturing processes. With the ability to cut through thick steel plates at high speeds, {Company Name} is able to deliver orders in a timely manner, meeting even the most demanding deadlines.Furthermore, laser cutting technology has minimized material waste, as it allows for precise nesting and optimization of steel plates. This not only contributes to cost savings for manufacturers but also aligns with sustainable and eco-friendly manufacturing practices.With a team of skilled engineers and technicians, {Company Name} offers personalized support to clients, from the initial design phase to the final production of steel plate components. Their expertise in laser cutting technology ensures that clients receive top-quality products that meet their exact specifications.In addition to their commitment to precision and efficiency, {Company Name} places great emphasis on quality control and safety in their manufacturing processes. Their state-of-the-art facilities are equipped with the latest safety measures, ensuring a secure and controlled environment for laser cutting operations.As a company dedicated to continuous improvement, {Company Name} stays abreast of the latest advancements in laser cutting technology. They regularly invest in training and development, ensuring that their team remains at the forefront of industry trends and best practices.The adoption of laser cut steel plate technology has had a profound impact on the manufacturing industry, offering a level of precision and efficiency that was previously unattainable. {Company Name} has embraced this technology, leveraging it to provide unparalleled cutting services to their clients across various industries.In conclusion, the introduction of laser cut steel plate technology has transformed the manufacturing landscape, and {Company Name} is leading the charge in delivering exceptional precision and efficiency to their clients. With a focus on innovation, quality, and customer satisfaction, {Company Name} remains a trusted partner for all steel plate cutting needs.

Top Benefits of Using a CNC Fiber Cutting Machine for Your Business

s article on the efficiency and benefits of using a CNC Fiber Cutting MachineCNC Fiber Cutting Machine, the latest innovation in the world of fiber cutting technology, has taken the industry by storm. A high-tech machine that can cut through various materials with precision and speed, a CNC Fiber Cutting Machine has revolutionized the industry, making production processes faster, more efficient, and more cost-effective.At the forefront of this innovation is the company behind the CNC Fiber Cutting Machine. This company has been designing and manufacturing cutting-edge machines for the industrial sector for close to two decades, transforming the industry with their innovative designs and technologies. With the release of the CNC Fiber Cutting Machine, the company has taken the industry to the next level, fueling the demand for faster and more accurate production processes.The CNC Fiber Cutting Machine employs the use of high-powered lasers to cut through various materials such as steel, aluminum, and copper with remarkable precision. The machine is equipped with advanced software that allows for intricate designs to be programmed into the system, giving the machine the ability to cut complex shapes and patterns with ease. This technology provides significant advantages over traditional cutting methods, making it the preferred cutting machine for modern industrial processes.The CNC Fiber Cutting Machine also offers numerous benefits to the operator and production facilities. The first and most notable benefit is the speed at which the machine operates. The CNC Fiber Cutting Machine has a cutting speed that is ten times faster than traditional cutting methods. This rapid speed translates into a significant increase in production capacity, lowering lead times and improving overall productivity.Another significant benefit of the CNC Fiber Cutting Machine is the high level of accuracy and precision it provides. The advanced software and laser technology employed in the machine ensure that every cut is precise, and the final product is of superior quality. This level of accuracy is crucial in the cutting of intricate designs and the creation of precise parts for various industrial applications.The CNC Fiber Cutting Machine also has a high level of versatility, making it suitable for various cutting applications. The machine can cut through a wide range of materials, and it can be programmed to create virtually any design. This versatility allows for multiple production processes to be consolidated into a single machine, making the entire operation more cost-effective.One of the most significant benefits of the CNC Fiber Cutting Machine is its efficiency in material utilization. The machine cuts with minimal kerf width, eliminating material waste during the cutting process. This reduced wastage translates into significant cost savings for production facilities, making the CNC Fiber Cutting Machine a smart and efficient investment.The CNC Fiber Cutting Machine is also remarkably easy to operate and maintain. The software is user-friendly, allowing operators to program the machine with ease and accuracy. The machine's design is also optimized for ease of maintenance, reducing downtime and ensuring that the machine operates at peak efficiency at all times.In conclusion, the CNC Fiber Cutting Machine is a game-changer in the world of industrial cutting processes. Its speed, precision, versatility, and efficiency make it the preferred cutting machine for modern production facilities. The benefits of this machine are numerous, including increased production output, improved quality, reduced material waste, and ease of operation and maintenance. With the CNC Fiber Cutting Machine, production facilities can take their operations to the next level, improve their output, and remain competitive in an ever-changing market.

Advanced Cutting System: New Technology for Precision and Efficiency

Cutting System Revolutionizes the Manufacturing IndustryThe manufacturing industry is constantly evolving, with new technologies and innovations driving efficiency and productivity. One such innovation is the cutting system developed by a leading manufacturing company. This cutting system is revolutionizing the industry, offering precision and speed like never before.The cutting system, developed by the company, is a state-of-the-art solution for cutting various materials with unmatched accuracy. It utilizes advanced technology and high-quality materials to deliver precise cuts, making it ideal for a wide range of applications in the manufacturing industry.With a focus on innovation and cutting-edge technology, the company has been at the forefront of manufacturing solutions for decades. Their cutting system is the latest addition to their impressive lineup of products, and it is quickly gaining recognition for its exceptional performance and reliability.One of the key features of the cutting system is its versatility. It is capable of cutting a wide range of materials, including metal, plastic, and composites, with exceptional precision. This versatility makes it a valuable tool for manufacturers across various industries, from automotive and aerospace to consumer goods and electronics.In addition to its versatility, the cutting system also offers unmatched speed and efficiency. It is equipped with advanced software and automation capabilities that streamline the cutting process, reducing production time and increasing throughput. This level of speed and efficiency is crucial for manufacturers looking to stay competitive in today's fast-paced market.Furthermore, the cutting system is designed with user-friendly features that make it easy to operate and maintain. Its intuitive interface and comprehensive support resources make it accessible to operators of all skill levels, ensuring that manufacturers can maximize the system's potential without extensive training or technical expertise.The company has also prioritized safety in the design of the cutting system, incorporating protective measures to safeguard operators and prevent accidents. This commitment to safety reflects the company's dedication to providing not only high-performance solutions but also reliable and secure tools for the manufacturing industry.The cutting system is also supported by a team of experts who are available to provide technical assistance, training, and guidance to users. This level of support ensures that manufacturers can make the most of the system and address any challenges or issues that may arise.As a result of its exceptional performance and reliability, the cutting system has garnered widespread praise from manufacturers who have implemented it into their production processes. Customer testimonials and case studies have highlighted the system's ability to significantly improve precision, efficiency, and overall productivity.In summary, the cutting system developed by the company is a game-changer for the manufacturing industry. Its precision, speed, versatility, and user-friendly design make it a valuable asset for manufacturers across various sectors. As the industry continues to evolve, this cutting system is poised to play a crucial role in driving efficiency and innovation for years to come.

Innovative Technology Allows for Electric Bending in Construction Projects

Electric Bending, a revolutionary new technology in the field of industrial manufacturing, is set to transform the way we think about bending metal. This groundbreaking innovation, developed by a leading company, is expected to significantly improve efficiency, precision, and sustainability in metal bending processes.With its state-of-the-art electric actuation system, Electric Bending offers several advantages over traditional hydraulic bending methods. The precision and speed of the electric system enable more accurate and efficient bending of metal components, resulting in higher quality finished products. Additionally, the electric system drastically reduces energy consumption, making it a more sustainable and environmentally friendly option for industrial manufacturing.One of the key benefits of Electric Bending is its adaptability to various metal materials, including aluminum, steel, and copper. This versatility makes it an ideal solution for a wide range of industries, from automotive and aerospace to construction and infrastructure development. By allowing for precise and reliable manipulation of different metals, Electric Bending opens up new possibilities for manufacturers to create complex and innovative metal components.The company behind this groundbreaking technology, a global leader in industrial automation and advanced manufacturing solutions, has a long-standing reputation for pushing the boundaries of what is possible in the field of industrial engineering. With a strong focus on research and development, the company has consistently been at the forefront of innovation, developing cutting-edge technologies that have revolutionized the way businesses operate and produce.In addition to Electric Bending, the company offers a comprehensive range of advanced manufacturing solutions, including robotic automation, additive manufacturing, and digital transformation services. By combining expertise in these areas, the company is able to provide integrated solutions that optimize production processes, improve product quality, and reduce manufacturing costs.The development of Electric Bending is a testament to the company's commitment to driving innovation in the industrial manufacturing sector. By leveraging its expertise in electric actuation technology and materials science, the company has succeeded in creating a game-changing solution that has the potential to reshape the metal bending industry.The impact of Electric Bending is expected to be far-reaching, with manufacturers across various industries poised to benefit from its advanced capabilities. By streamlining and enhancing the metal bending process, Electric Bending has the potential to drive significant improvements in productivity and product quality, ultimately resulting in a competitive edge for businesses that adopt this cutting-edge technology.Furthermore, the sustainability benefits of Electric Bending are in line with the growing emphasis on environmentally friendly manufacturing practices. By reducing energy consumption and minimizing waste, Electric Bending aligns with the broader trend toward sustainable and eco-friendly industrial operations.As Electric Bending continues to gain traction in the manufacturing industry, the company is committed to supporting its customers in adopting and integrating this innovative technology into their operations. Through comprehensive training, technical support, and ongoing maintenance services, the company aims to ensure that businesses can fully harness the potential of Electric Bending to improve their manufacturing processes and achieve their production goals.In conclusion, Electric Bending represents a significant leap forward in the field of metal bending, offering a combination of precision, efficiency, and sustainability that is unmatched by traditional bending methods. With the backing of a leading company renowned for its expertise in industrial automation, Electric Bending is well-positioned to drive positive change in the manufacturing industry, paving the way for a new era of advanced and sustainable metal bending processes.