Innovative Machinery and Equipment for Increased Efficiency and Productivity

By:Admin

With a strong focus on research and development, Machine And Equipment (name removed) has been able to consistently deliver cutting-edge technology to their clients. Their team of highly skilled engineers and designers work tirelessly to create state-of-the-art machinery that is tailored to meet the specific needs of their customers.

The company's commitment to quality and innovation has earned them a reputation as a leader in the industrial machinery sector. Their attention to detail and dedication to providing top-notch products has made them a trusted partner for businesses across various industries.

One of Machine And Equipment's (name removed) standout features is their flexibility and ability to customize machinery to suit the unique requirements of their clients. This allows them to provide tailored solutions that address specific challenges and provide tangible results. Whether it is a large-scale manufacturing facility or a small-scale production line, Machine And Equipment (name removed) has the expertise and technology to meet the demands of any project.

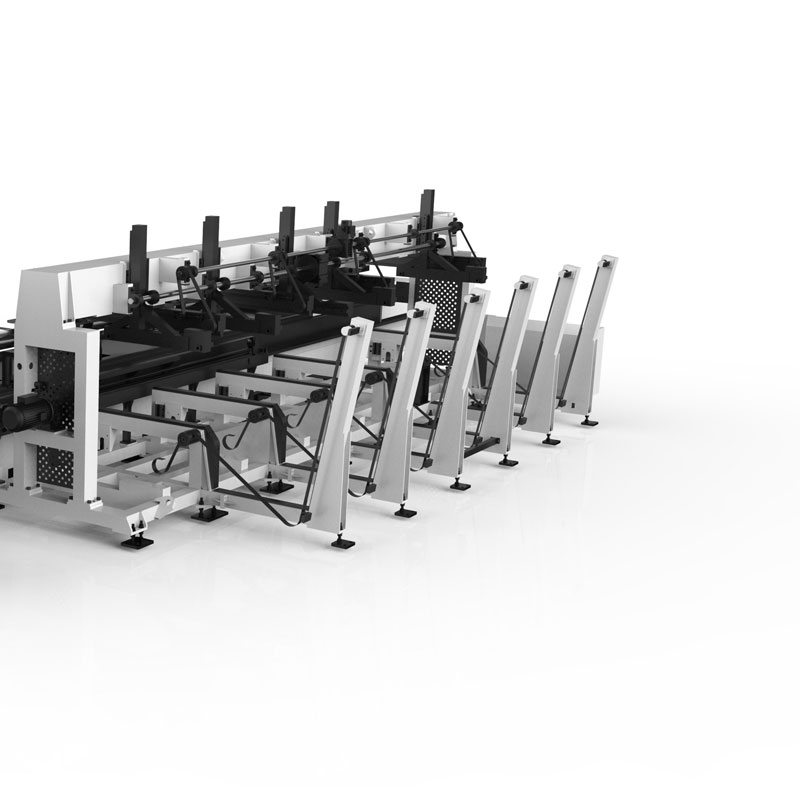

Their latest machinery, which is currently making waves in the industry, is a testament to their commitment to innovation and excellence. This new equipment boasts advanced features and functionalities that set it apart from other offerings in the market. Designed with the latest technology and manufactured using the highest quality materials, this machinery promises to deliver unmatched performance and reliability.

Machine And Equipment (name removed) has also maintained a strong focus on sustainability and environmental responsibility, ensuring that their machinery is not only efficient but also eco-friendly. This has become increasingly important in the industry as more companies seek to minimize their environmental impact and promote sustainable practices.

In addition to their exceptional products, Machine And Equipment (name removed) also offers comprehensive after-sales service and support to ensure that their clients get the most out of their investments. Their team of technicians and engineers are readily available to provide maintenance and repairs, as well as technical assistance to address any issues that may arise.

With a proven track record of success and a commitment to excellence, Machine And Equipment (name removed) continues to cement their position as a leading provider of industrial machinery. Their unwavering dedication to quality, innovation, and customer satisfaction sets them apart in the competitive market, making them the go-to choice for businesses seeking reliable and efficient machinery solutions.

As the industry continues to evolve and demand for advanced machinery grows, Machine And Equipment (name removed) remains at the forefront, constantly pushing the boundaries of what is possible and redefining industry standards. Their latest launch is a testament to their ongoing commitment to excellence and their ability to meet the ever-changing needs of their clients.

In conclusion, Machine And Equipment (name removed) has once again proven their expertise and dedication to providing cutting-edge machinery solutions. Their latest launch represents a significant milestone in the industry and reaffirms their position as a leader in the field. With a strong focus on innovation, quality, and customer satisfaction, it is no wonder that Machine And Equipment (name removed) continues to be the preferred choice for businesses seeking reliable and efficient machinery.

Company News & Blog

Ultimate guide to CNC sheet metal cutting

CNC Sheet Metal Cutting: A Game-Changer in the Manufacturing IndustryIn today's rapidly evolving manufacturing industry, the demand for precision and efficiency has never been higher. Companies are constantly seeking new and innovative ways to streamline their production processes and deliver high-quality products in a timely manner. One of the most significant advancements in the industry has been the introduction of CNC sheet metal cutting technology.CNC (Computer Numerical Control) sheet metal cutting is a method of manufacturing that uses computer-controlled machines to precisely cut and shape sheets of metal. This technology has revolutionized the way companies produce metal components, allowing for increased precision, improved efficiency, and reduced lead times.{} has been at the forefront of this technological revolution, leading the way with their state-of-the-art CNC sheet metal cutting services. With a proven track record of delivering high-quality products to a wide range of industries, {} has solidified its position as a market leader in the manufacturing sector.The company's CNC sheet metal cutting capabilities are truly impressive, offering a level of precision and accuracy that was previously unattainable with traditional cutting methods. By utilizing advanced CAD/CAM software and cutting-edge machinery, {} is able to produce complex and intricate metal components with remarkable speed and efficiency.One of the key advantages of CNC sheet metal cutting is its ability to produce highly detailed and intricate designs with ease. This level of precision is especially valuable in industries such as aerospace, automotive, and electronics, where components must meet strict tolerances and specifications.Furthermore, CNC sheet metal cutting allows for greater flexibility in production, enabling companies to easily adapt to design changes and produce custom components without the need for costly tooling adjustments. This level of adaptability is crucial in an industry that is constantly evolving and demands quick turnarounds.In addition to its precision and flexibility, CNC sheet metal cutting also offers significant cost savings for manufacturers. By automating the cutting process and minimizing material waste, companies can reduce production costs and ultimately improve their bottom line. This cost-effective solution has made CNC sheet metal cutting an attractive option for companies looking to optimize their production processes.{}'s commitment to excellence and innovation has set them apart in the competitive manufacturing landscape. With their extensive experience and expertise in CNC sheet metal cutting, they have successfully delivered high-quality products to a diverse range of clients, earning a reputation for reliability and professionalism.By harnessing the power of CNC sheet metal cutting technology, {} continues to drive the industry forward, offering cutting-edge solutions that meet the evolving needs of modern manufacturing. As the demand for precision and efficiency continues to grow, CNC sheet metal cutting is poised to play a pivotal role in shaping the future of the industry.In conclusion, CNC sheet metal cutting has revolutionized the manufacturing industry, offering unparalleled precision, flexibility, and cost savings. With {}'s expertise and cutting-edge technology, they have positioned themselves as a leading provider of CNC sheet metal cutting services, driving the industry forward and delivering top-quality products to satisfied customers. As the industry continues to evolve, CNC sheet metal cutting will undoubtedly remain a game-changer, shaping the future of manufacturing for years to come.

Top 10 Best Machine Equipment to Upgrade Your Operations

Machine Equipment, a leading provider of industrial machinery, is proud to announce the launch of its latest innovation in the field of heavy machinery. The company has a long-standing reputation for delivering high-quality, reliable equipment to a wide range of industries, and this new product is set to continue that tradition.The new machine, which is designed for use in heavy industrial settings, is the result of years of research and development. It has been engineered to meet the needs of the most demanding applications, and is built to withstand the rigors of heavy use. With a focus on durability, reliability, and performance, the new machine promises to be a game-changer for companies in need of high-quality industrial equipment."We are thrilled to introduce this new machine to the market," said the company's CEO. "We have worked tirelessly to develop a product that not only meets but exceeds the expectations of our customers. With its advanced technology and robust construction, we believe it will set a new standard for heavy machinery in the industry."The machine features a number of innovative design elements that set it apart from the competition. Its advanced control system, for example, provides operators with intuitive, easy-to-use functionality, allowing for precise and efficient operation. Additionally, the machine's robust construction ensures that it can easily withstand the toughest working conditions, making it an ideal choice for a wide range of applications.In addition to its advanced design, the new machine also boasts a number of features aimed at improving efficiency and productivity. Its powerful engine, for example, delivers exceptional performance while minimizing fuel consumption, helping to reduce operating costs and environmental impact. Furthermore, its easy maintenance design ensures that downtime is kept to a minimum, allowing for maximum productivity and uptime.With a focus on customer satisfaction, Machine Equipment has also invested heavily in providing comprehensive support for the new machine. From expert technical assistance to a full range of spare parts and accessories, the company is committed to ensuring that customers have everything they need to get the most out of their investment. This dedication to customer service is just one of the many reasons why Machine Equipment has earned a reputation as a trusted partner for companies around the world.As the demand for heavy machinery continues to grow, the introduction of this new machine represents a significant step forward for Machine Equipment. With its advanced technology, durable construction, and focus on performance and reliability, it is sure to make a strong impression on the industry. Whether used in construction, mining, or any other heavy industrial application, the new machine promises to deliver outstanding results for its users.As the company looks to the future, it is clear that the introduction of this new machine is just the beginning. With a commitment to innovation, quality, and customer satisfaction, Machine Equipment is well-positioned to remain a leader in the field of industrial machinery for years to come. Whether developing new products, expanding its service offerings, or strengthening its global presence, the company is dedicated to continuing to meet and exceed the needs of its customers, making Machine Equipment a name to watch in the world of heavy machinery.

Ultimate Guide to Stainless Steel Laser Welding

Stainless Steel Laser Welding Technology on the Rise: A Game Changer in Manufacturing IndustryIn today's increasingly competitive manufacturing industry, the demand for high-quality, precise, and efficient welding technologies is at an all-time high. With the growing popularity of stainless steel in various applications, the need for advanced welding techniques has become more pressing than ever. This is where the innovative stainless steel laser welding technology comes into play, revolutionizing the way stainless steel components are fabricated and assembled.Laser welding is a cutting-edge technology that utilizes a highly focused beam of light energy to melt and fuse metal components together. This technique offers several advantages over traditional welding methods, including higher precision, reduced heat-affected zones, and minimal distortion of the base material. As a result, laser welding has become the preferred choice for joining stainless steel components in industries such as automotive, aerospace, medical, and consumer goods.One company that has been at the forefront of stainless steel laser welding technology is {}. With over two decades of experience in laser welding and precision manufacturing, {} has established itself as a leader in the field of advanced welding solutions. The company's state-of-the-art facilities and highly skilled engineering team have enabled them to develop and perfect stainless steel laser welding techniques that meet the exacting standards of their diverse clientele.{}'s stainless steel laser welding capabilities are powered by a combination of cutting-edge laser systems, advanced robotics, and proprietary process control software. This integrated approach allows {} to achieve exceptional welding precision, consistency, and repeatability, even with the most complex and intricate stainless steel components. Whether it's welding thin gauge sheets or thick-walled tubes, {}'s laser welding technology delivers superior results with unmatched efficiency.One of the key advantages of {}'s stainless steel laser welding technology is its ability to ensure minimal distortion and heat-affected zones in the welded components. This is crucial for applications that require high dimensional accuracy and structural integrity, such as medical implants, aerospace components, and automotive assemblies. By minimizing the impact of heat on the base material, {}'s laser welding process produces welds that exhibit superior mechanical properties and corrosion resistance.Furthermore, {}'s laser welding technology offers unmatched versatility, making it suitable for a wide range of stainless steel alloys, including austenitic, ferritic, and duplex grades. This flexibility allows {} to cater to the diverse needs of their clients, offering tailored welding solutions that are optimized for specific material properties, joint designs, and production volumes. As a result, {} has been able to not only meet but exceed the expectations of their customers across various industries.In addition to its technical prowess, {}'s commitment to quality and innovation sets it apart as a preferred partner for companies seeking cutting-edge welding solutions. The company's ISO-certified quality management system, rigorous process validation protocols, and continuous investment in research and development ensure that its stainless steel laser welding technology remains at the forefront of industry standards. As a testament to its dedication to excellence, {} has received numerous accolades and certifications from leading industry organizations and regulatory bodies.Looking ahead, the future of stainless steel laser welding technology looks incredibly promising, with continued advancements in laser technology, automation, and digital integration. As manufacturing demands become more complex and stringent, the need for precision welding solutions will only grow, positioning {} as a key player in shaping the industry's landscape. With a strong focus on innovation, quality, and customer satisfaction, {} is poised to continue leading the way in stainless steel laser welding technology, empowering manufacturers to achieve new heights of efficiency and performance in their production processes.

Laser Machinery Market Experiences Surge in Demand as Industries Adapt to Advanced Technologies

Title: Advancements in Laser Machinery Revolutionizing Industrial ManufacturingIntroduction:In the dynamic world of industrial manufacturing, laser machinery has emerged as a powerful tool that offers precision, speed, and flexibility. With its ability to cut, engrave, weld, and mark various materials, laser technology has revolutionized numerous industries including automotive, aerospace, electronics, and healthcare. One of the leading players in this market is a renowned company that specializes in cutting-edge laser equipment.Company Background:With several decades of industry expertise, the company has become a global leader in developing cutting-edge laser machinery. Renowned for its commitment to innovation, the company has consistently delivered high-quality products to its clientele worldwide. Its comprehensive range of laser machines cater to a diverse array of industrial applications, from small-scale enterprises to large-scale manufacturing plants.News Content:1. Introduction of Laser Machinery: The company's recently unveiled laser machinery series marks a significant milestone in the industry's progression. Designed to meet the evolving needs of manufacturers, these state-of-the-art machines offer enhanced capabilities and improved performance.2. Cutting-edge Laser Cutting Systems: The laser cutting systems from the company have gained wide acclaim for their ability to cut through a wide range of materials with unparalleled precision. Equipped with advanced laser sources and intelligent control systems, these machines deliver high-quality cuts with minimal material waste.3. Powerful Laser Engraving Solutions: The company's laser engraving solutions provide manufacturers with a versatile tool to add intricate designs, logos, and patterns to a variety of surfaces. These machines offer precise engraving across materials like wood, acrylic, metal, and glass, allowing businesses to customize their products effectively.4. Revolutionizing Manufacturing with Laser Welding: Laser welding machines have been pivotal in transforming the manufacturing landscape. Utilizing high-energy laser beams, these machines provide stronger welds, while minimizing deformation and heat-affected zones. The company's laser welding systems have been adopted by numerous industries, including automotive, electronics, and medical device manufacturing.5. Laser Marking for Traceability and Security: Laser marking technology has gained importance for its ability to create permanent markings on various materials, ensuring traceability and security. The company's laser marking systems offer quick, accurate, and legible markings, enabling businesses to comply with industry standards, improve product identification, and enhance brand recognition.6. Integration of Industry 4.0 Technologies: The company has integrated its laser machinery with Industry 4.0 technologies, enabling seamless connectivity, improved automation, and data-driven decision-making. Real-time monitoring, remote access, and advanced analytics optimize production processes, reduce downtime, and enhance overall operational efficiency.7. Commitment to Sustainability: As sustainability takes center stage in today's manufacturing landscape, the company remains committed to developing eco-friendly laser machinery. Their machines incorporate energy-saving features, reduce material waste, and adhere to stringent environmental standards.Conclusion:The company's pioneering contributions in laser machinery have propelled the industry forward, empowering manufacturers globally. By embracing innovation, continuously refining their products, and adapting to evolving market requirements, the company has established itself as a leader in the field. With its unwavering commitment to precision, speed, and sustainability, the company is set to shape the future of industrial manufacturing through its laser machinery solutions.

High-Powered Laser Tube Machine Delivers Exceptional Precision and Efficiency

Laser Tube Machine Revolutionizes Manufacturing IndustryIn today's rapidly evolving manufacturing industry, efficiency and precision are key factors in staying competitive and meeting the demands of an ever-changing market. As technology continues to advance, companies are constantly seeking innovative solutions to improve their production processes. One such solution that has gained the attention of industry leaders is the Laser Tube Machine.The Laser Tube Machine, produced by a leading manufacturing equipment company, has proven to be a game changer in the industry. This revolutionary piece of equipment has the ability to cut and shape various materials with unparalleled precision and speed, making it an indispensable tool for manufacturers in a wide range of industries.The Laser Tube Machine utilizes cutting-edge technology to generate precise laser beams that can cut through materials such as metal, plastic, and wood with incredible accuracy. This not only streamlines the manufacturing process but also significantly reduces the margin of error, resulting in higher quality products.One of the key features of the Laser Tube Machine is its ability to handle tubes of varying shapes and sizes, making it a versatile solution for manufacturers with diverse production needs. Additionally, the machine's automated functions and user-friendly interface make it easy for operators to program and monitor the cutting process, further enhancing efficiency and reducing the need for manual labor.The company behind the Laser Tube Machine has a longstanding reputation for producing cutting-edge manufacturing equipment. With a strong focus on research and development, the company has consistently delivered innovative solutions that have helped numerous businesses enhance their production capabilities.The company's commitment to quality and customer satisfaction has made them a trusted partner for manufacturers across the globe. Their team of skilled engineers and technicians work tirelessly to ensure that their products meet the highest industry standards, providing customers with reliable and advanced equipment that aligns with their evolving needs.In addition to the Laser Tube Machine, the company offers a comprehensive range of manufacturing solutions, including laser cutting machines, CNC routers, and plasma cutting machines. Their dedication to providing industry-leading equipment has positioned them as a leader in the manufacturing technology sector.The introduction of the Laser Tube Machine has already made a significant impact on the manufacturing industry. Companies that have integrated this cutting-edge technology into their production processes have reported substantial improvements in efficiency, productivity, and product quality.According to a spokesperson from the manufacturing equipment company, "The Laser Tube Machine represents a significant advancement in manufacturing technology. Its precision and speed have enabled our customers to take their production capabilities to new heights, allowing them to meet the demands of today's competitive market."The impact of the Laser Tube Machine is not only limited to large-scale manufacturers. Small and medium-sized businesses have also benefitted from this innovative technology, as it has allowed them to compete on a level playing field with larger companies, offering them the opportunity to expand their capabilities and grow their businesses.As the manufacturing industry continues to evolve, the Laser Tube Machine is expected to play a pivotal role in shaping the future of production processes. Its ability to deliver precision, efficiency, and versatility makes it a valuable asset for manufacturers across various industries, setting new standards for quality and productivity.With the revolutionary technology of the Laser Tube Machine and the commitment of the manufacturing equipment company to provide advanced solutions, the industry is poised to experience a new era of innovation and efficiency. As more companies embrace this cutting-edge technology, the potential for growth and advancement in the manufacturing sector is limitless.

Powerful Fiber Laser: The Latest Advancement in Laser Technology

[Company Name], a leading provider of industrial laser solutions, has introduced a groundbreaking 20 kW fiber laser that is set to revolutionize the cutting and welding industries. This new laser, which is the most powerful of its kind in the market, will enable manufacturers to significantly increase their productivity and efficiency.The 20 kW fiber laser is designed to deliver superior performance and precision in a wide range of applications, including cutting, welding, and surface treatment. With its cutting-edge technology and high-powered output, it is capable of processing a variety of materials, such as steel, aluminum, copper, and brass, with exceptional speed and accuracy.One of the key features of the 20 kW fiber laser is its high energy efficiency, which allows manufacturers to reduce their operating costs and environmental impact. The laser is equipped with advanced cooling systems and control mechanisms that optimize energy consumption and minimize waste, making it a sustainable and cost-effective solution for industrial processing.In addition to its impressive power and efficiency, the 20 kW fiber laser also offers advanced connectivity and automation capabilities. It can be integrated with robotic systems and computer-aided manufacturing software, allowing for seamless production processes and real-time monitoring and control."We are thrilled to introduce the 20 kW fiber laser to the market," says [Company Name]'s CEO. "This cutting-edge technology represents a significant advancement in industrial laser processing, and we are confident that it will enable our customers to achieve new levels of performance and productivity."The introduction of the 20 kW fiber laser is part of [Company Name]'s commitment to innovation and continuous improvement. With over [number] years of experience in the industry, the company has established itself as a pioneer in the development of high-quality laser solutions for a wide range of industrial applications.[Company Name] offers a comprehensive range of laser products and services, including fiber lasers, CO2 lasers, and diode lasers, as well as custom-designed solutions tailored to the specific needs of its customers. Its team of experts provides consulting, training, and technical support to ensure the successful implementation and operation of its laser systems.The company's state-of-the-art manufacturing facilities and R&D center are equipped with the latest tools and technologies for product development and testing. Its stringent quality control processes and industry certifications ensure that its laser solutions meet the highest standards of performance and reliability.In addition to its technological expertise, [Company Name] is dedicated to customer satisfaction and long-term partnerships. It works closely with its clients to understand their requirements and provide tailored solutions that address their unique challenges and objectives."Customer satisfaction is at the heart of everything we do," says [Company Name]'s CEO. "We are committed to delivering exceptional value and support to our customers, and the introduction of the 20 kW fiber laser is a testament to that commitment."With the launch of the 20 kW fiber laser, [Company Name] is poised to set new standards in the industrial laser industry and reinforce its position as a leading provider of innovative and reliable laser solutions. As manufacturers continue to seek ways to enhance their productivity and competitiveness, this groundbreaking technology is expected to have a significant impact on the future of industrial processing.

Top Cutting Machine for Precision Cutting - A Game Changer for Your Business

At the cutting edge of innovation: SS Cutting Machine revolutionizes the manufacturing industryIn today's fast-paced and competitive manufacturing industry, companies are constantly seeking ways to streamline their production processes and improve efficiency. This is where SS Cutting Machine comes into play, offering state-of-the-art cutting solutions that are revolutionizing the way companies produce their goods.With a rich history spanning over 30 years, SS Cutting Machine has established itself as a leader in the field of cutting technology. The company has a strong focus on research and development, constantly pushing the boundaries of what is possible in the realm of cutting machinery. By staying ahead of the curve, SS Cutting Machine has been able to consistently deliver cutting-edge solutions that meet the ever-evolving needs of the industry.One of the key differentiators for SS Cutting Machine is its commitment to innovation. The company's team of engineers and designers are continuously working on new and improved cutting technologies, ensuring that their machines are always at the forefront of the industry. This dedication to innovation has allowed SS Cutting Machine to develop cutting solutions that are not only highly precise and efficient, but also customizable to meet the specific needs of each individual customer.A cornerstone of the company's success is their unwavering dedication to quality. SS Cutting Machine takes great pride in the craftsmanship and precision of their machines, ensuring that each one is built to the highest standards. This commitment to quality has earned SS Cutting Machine a stellar reputation within the industry, with many companies turning to them as their go-to provider for cutting solutions.One of the standout products from SS Cutting Machine is their high-speed laser cutting machine. This cutting-edge technology has revolutionized the way companies approach cutting processes, offering unparalleled speed and precision. By harnessing the power of laser technology, SS Cutting Machine has been able to develop a machine that is capable of cutting through a wide range of materials with incredible accuracy, making it the ideal solution for companies looking to streamline their production processes.Another area where SS Cutting Machine shines is in their customer service and support. The company understands that each customer has unique needs and requirements, and they go above and beyond to ensure that those needs are met. From the initial consultation to after-sales support, SS Cutting Machine works closely with their clients to ensure that they are getting the most out of their cutting solutions.Looking ahead, SS Cutting Machine shows no signs of slowing down. With a strong focus on innovation, quality, and customer service, the company is well-positioned to continue leading the way in the cutting technology industry. As the manufacturing industry continues to evolve, companies can rest assured that SS Cutting Machine will be there every step of the way, providing cutting solutions that are second to none.In conclusion, SS Cutting Machine has set the bar high for cutting technology, offering innovative solutions that are revolutionizing the manufacturing industry. With a strong focus on innovation, quality, and customer service, the company has solidified its position as a leader in the field of cutting machinery. As the industry continues to evolve, companies can rely on SS Cutting Machine to deliver cutting solutions that are at the cutting edge of innovation.

Increased Fiber Laser Cutting Speed for Improved Efficiency and Productivity

Fiber Laser Cutting Speed Revolutionizes Manufacturing IndustryIn today's fast-paced world, efficiency is a key factor in the manufacturing industry. As technology continues to advance, companies are constantly looking for ways to improve their processes and increase their productivity. One such advancement that is making waves in the industry is the development of fiber laser cutting technology.Fiber laser cutting is a process that uses a high-powered laser to cut materials with incredible precision and speed. This technology has revolutionized the manufacturing industry, allowing companies to produce high-quality products at a faster rate than ever before. In fact, the speed of fiber laser cutting has completely transformed the way many manufacturing companies operate.One company at the forefront of this technology is {}. As a leading provider of fiber laser cutting machines, {} has been instrumental in the development and implementation of this groundbreaking technology. With their state-of-the-art equipment and innovative solutions, {} is helping companies around the world streamline their manufacturing processes and stay ahead of the competition.The secret behind the speed of fiber laser cutting lies in the technology itself. Unlike traditional cutting methods, which rely on mechanical force to cut through materials, fiber laser cutting uses a highly focused laser beam to melt or vaporize the material. This not only results in a much cleaner and more precise cut, but it also allows for significantly faster cutting speeds.The benefits of this increased speed are substantial. Companies are able to produce more parts in less time, leading to higher productivity and lower production costs. In addition, the precision of fiber laser cutting means that there is less material waste, further reducing costs and environmental impact.One of the key advantages of {}'s fiber laser cutting machines is their ability to cut a wide range of materials, from metal and plastic to composites and ceramics. This versatility makes them invaluable to a variety of industries, including automotive, aerospace, and electronics. With the ability to handle such a diverse range of materials, {}'s machines are a valuable asset to any manufacturing operation.In addition to their cutting-edge technology, {} also provides top-notch service and support to their customers. Their team of experts works closely with each client to understand their specific needs and provide tailored solutions. Whether it's optimizing cutting parameters for a specific material or providing training and technical assistance, {} is committed to ensuring that their customers get the most out of their equipment.The impact of fiber laser cutting speed on the manufacturing industry cannot be overstated. With the ability to produce high-quality parts at a faster rate than ever before, companies are able to meet increasing demand and stay competitive in a rapidly evolving market. And with the support of companies like {}, the future of manufacturing looks brighter than ever.As technology continues to advance, it's clear that fiber laser cutting will play an increasingly important role in the manufacturing industry. With its unmatched speed and precision, this technology is reshaping the way companies produce goods and driving the industry forward. For companies looking to stay ahead of the curve, investing in fiber laser cutting technology is a surefire way to increase efficiency and profitability. And with the support of innovative companies like {}, the possibilities are endless.

Advanced Small Laser Welder for Precision Welding Applications

Small Laser Welder Revolutionizing Precision Welding in Manufacturing IndustryIn today's fast-paced manufacturing industry, precision and efficiency are two key factors that can make or break a company's success. With the increasing demand for high-quality products and the need for faster production times, manufacturers are constantly seeking innovative solutions to enhance their welding processes. This is where the small laser welder comes into play, revolutionizing precision welding in the manufacturing industry.{Company} is a leading provider of advanced laser technology solutions, specializing in cutting-edge laser systems that are designed to meet the needs of modern manufacturing processes. The company has recently introduced a small laser welder that has been making waves in the industry, setting new standards for precision welding and enhancing the efficiency of production lines.The small laser welder is a compact yet powerful tool that is designed to deliver precise and clean welds on a wide range of materials, including metals, plastics, and ceramics. Its advanced laser technology allows for pinpoint accuracy and control, ensuring that every weld is of the highest quality and meets the strictest industry standards.One of the key features of the small laser welder is its versatility. Whether it's joining small parts with intricate geometries or welding delicate components with minimal heat input, this innovative tool is capable of handling a variety of welding tasks with ease. Its compact size also makes it ideal for use in tight spaces and for applications where traditional welding methods may be impractical.Furthermore, the small laser welder offers significant advantages over conventional welding techniques. By utilizing a focused laser beam, it minimizes the heat-affected zone and eliminates the need for additional filler materials, resulting in cleaner and more efficient welds. This not only improves the overall quality of the welding process but also reduces the risk of distortion and material damage.In addition to its precision and efficiency, the small laser welder is also highly cost-effective. Its minimal energy consumption and low maintenance requirements make it a viable long-term investment for manufacturers looking to streamline their welding operations and reduce production costs. Furthermore, its user-friendly interface and intuitive controls make it accessible to operators of all skill levels, eliminating the need for extensive training or specialized expertise.{Company}'s small laser welder is already making a significant impact in the manufacturing industry, with numerous companies adopting this cutting-edge technology to enhance their welding processes. With its unmatched precision, efficiency, and versatility, it is poised to become an indispensable tool for manufacturers seeking to stay ahead of the competition and meet the evolving demands of the market.As the demand for high-quality products continues to grow, the small laser welder is expected to play a vital role in the future of precision welding in the manufacturing industry. Its innovative technology and proven performance are setting new standards for welding efficiency and quality, ultimately reshaping the way manufacturers approach their welding processes.In conclusion, {Company}'s small laser welder represents a significant leap forward in precision welding technology, offering unparalleled accuracy, efficiency, and versatility for manufacturers seeking to elevate their welding processes to new heights. With its advanced laser technology and impressive performance, it is truly revolutionizing precision welding in the manufacturing industry and setting a new standard for excellence.

High Precision Metal Cutting Machine for Complete Coverage

Whole Cover Metal Cutting Machine Revolutionizes Metal Fabrication IndustryIn today’s fast-paced world, the demand for efficient and high-quality metal cutting machines has never been higher. As industries continue to grow and innovate, the need for advanced technology to streamline production processes has become paramount. In response to this demand, {company name}, a leading manufacturer of industrial equipment, has introduced their latest innovation in metal cutting technology – the Whole Cover Metal Cutting Machine.With over 20 years of experience in the industry, {company name} has built a reputation for delivering cutting-edge solutions that meet the needs of their customers. The company’s commitment to innovation and quality is evident in their new Whole Cover Metal Cutting Machine, which promises to revolutionize the metal fabrication industry.The Whole Cover Metal Cutting Machine is designed to provide accurate, efficient, and precise cutting of various types of metal, including steel, aluminum, and stainless steel. What sets this machine apart from others in the market is its unique whole cover design, which provides a fully enclosed cutting area to ensure operator safety and minimize the risk of accidents. In addition, the machine is equipped with advanced laser technology that allows for high-speed cutting without compromising on accuracy and quality.One of the key features of the Whole Cover Metal Cutting Machine is its user-friendly interface, which allows operators to easily program and control the cutting process. This makes the machine suitable for a wide range of applications, from small-scale workshops to large-scale manufacturing facilities. Furthermore, the machine is designed to be energy-efficient, reducing operating costs and environmental impact.In addition to its technical capabilities, {company name}’s dedication to customer satisfaction is evident in the after-sales support and service offered with the Whole Cover Metal Cutting Machine. The company provides comprehensive training for operators, as well as ongoing maintenance and technical support to ensure optimal performance and longevity of the machine.The introduction of the Whole Cover Metal Cutting Machine comes at a time when the metal fabrication industry is undergoing rapid advancements in technology and automation. With the increasing demand for precision and efficiency in metal cutting processes, {company name}’s new machine is poised to make a significant impact on the industry."We are thrilled to introduce the Whole Cover Metal Cutting Machine to the market," said {company name}’s CEO. "This machine represents the culmination of years of research, development, and engineering, and we believe it will set a new standard for metal cutting technology. We are confident that our customers will benefit greatly from the capabilities and features of this machine."As the manufacturing landscape continues to evolve, the need for advanced metal cutting solutions will only continue to grow. {company name}’s Whole Cover Metal Cutting Machine is a testament to the company’s commitment to innovation and excellence, and it is set to redefine the way metal fabrication is done.With its advanced technology, safety features, and user-friendly design, the Whole Cover Metal Cutting Machine is poised to become a game-changer in the metal fabrication industry. As companies seek to improve their production processes and stay ahead of the competition, {company name}’s new machine provides a compelling solution that delivers on both performance and reliability.In conclusion, the introduction of {company name}’s Whole Cover Metal Cutting Machine represents a significant advancement in metal cutting technology. With its innovative design, advanced features, and commitment to customer satisfaction, the machine is set to make a lasting impact in the metal fabrication industry. As the industry continues to evolve, {company name} remains at the forefront of providing cutting-edge solutions that meet the needs of their customers.