Innovative Laser Machine Design: A Look at the Latest Technology and Applications

By:Admin

Laser technology has been revolutionizing the manufacturing industry for decades, and the latest innovation in this field comes from {} (Company introduction). Their newly designed laser machine, the {} Laser Machine, is set to transform production processes for a wide range of industries.

{} (Company introduction) has been a leading provider of cutting-edge technology solutions for industrial applications for over 20 years. Their team of experienced engineers and designers are dedicated to developing innovative solutions that meet the evolving needs of their clients. The introduction of the {} Laser Machine is a testament to their commitment to pushing the boundaries of what is possible in the manufacturing industry.

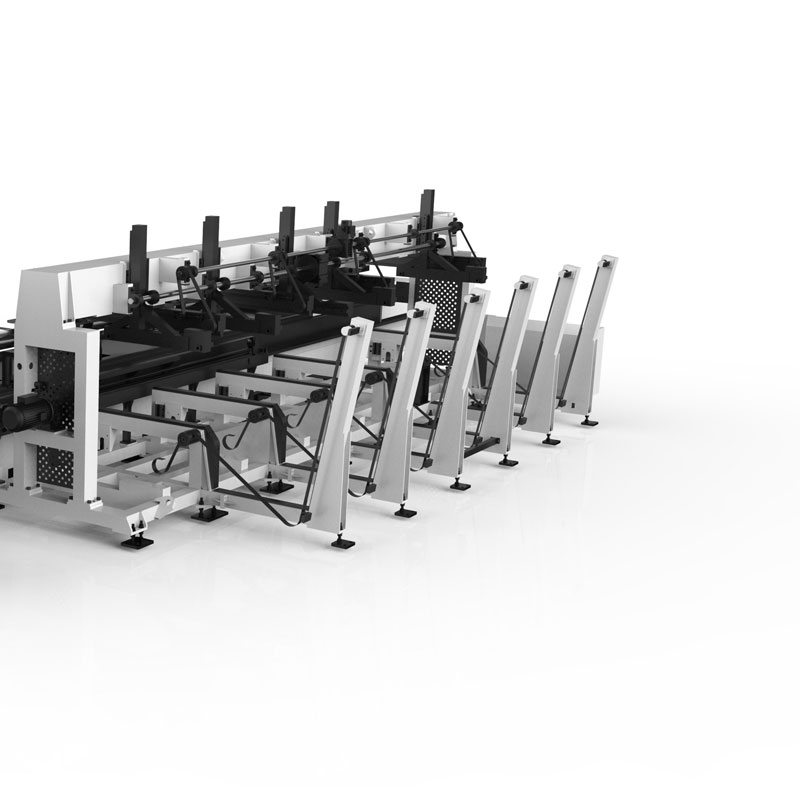

The {} Laser Machine is a state-of-the-art laser processing system that is designed to deliver high-precision results with unparalleled efficiency. The machine is equipped with advanced laser technology that allows for the precise cutting, engraving, and marking of various materials, including metals, plastics, and ceramics. This level of versatility makes the {} Laser Machine suitable for a wide range of industries, including automotive, aerospace, electronics, and medical device manufacturing.

One of the key features of the {} Laser Machine is its innovative design, which is focused on maximizing productivity and minimizing downtime. The machine is equipped with a high-speed laser cutting head that is capable of delivering rapid and accurate results, allowing for increased throughput and reduced lead times. Additionally, the machine is integrated with an intelligent control system that allows for seamless automation and remote monitoring, further optimizing the production process.

The {} Laser Machine is also designed with flexibility in mind, featuring a modular design that can be easily customized to meet the specific needs of different industries. This level of adaptability allows for the machine to be seamlessly integrated into existing production lines, providing a seamless transition to enhanced manufacturing capabilities.

In addition to its impressive performance capabilities, the {} Laser Machine is also designed with a focus on safety and sustainability. The machine is equipped with advanced safety features that ensure the protection of operators and the environment, while also minimizing energy consumption and waste generation. This commitment to responsible manufacturing aligns with {} (Company introduction)’s dedication to providing sustainable solutions for the industry.

The introduction of the {} Laser Machine is poised to have a significant impact on the manufacturing industry. With its advanced technology, high precision, and versatility, the machine is set to streamline production processes and drive innovation across various industries. As a company known for its dedication to excellence and customer satisfaction, {} (Company introduction) is confident that the {} Laser Machine will be a game-changer for their clients.

Looking to the future, {} (Company introduction) remains committed to pushing the boundaries of what is possible in the manufacturing industry. With their continued focus on innovation and customer-centric approach, they are well-positioned to lead the way in the integration of advanced technology solutions into production processes. As the industry continues to evolve, {} (Company introduction) is dedicated to delivering cutting-edge solutions that empower their clients to achieve new levels of success.

In conclusion, the introduction of the {} Laser Machine represents a significant milestone for {} (Company introduction) and the manufacturing industry as a whole. With its advanced technology, high precision, and versatility, the machine is set to revolutionize production processes and drive innovation across various industries. As {} (Company introduction) continues to lead the way in providing innovative technology solutions, the future looks brighter than ever for the manufacturing industry.

Company News & Blog

Top Laser Equipment Manufacturers You Should Know About

Laser Equipment Manufacturers, a leading company in the laser industry, has been providing cutting-edge laser technology to a wide range of industries for over 20 years. With a focus on innovation and customer satisfaction, the company has established itself as a trusted partner for businesses looking to integrate advanced laser technology into their operations.The company offers a diverse range of laser equipment, including laser cutting machines, laser marking systems, and laser welding machines. These products are designed to deliver high precision and efficiency, allowing businesses to achieve superior results in their manufacturing and processing operations. Laser Equipment Manufacturers takes pride in its commitment to quality and reliability, ensuring that each piece of equipment meets the highest standards of performance and durability.One of the key strengths of Laser Equipment Manufacturers is its dedication to research and development. The company continually invests in pioneering technology and processes, allowing it to stay ahead of the curve in an increasingly competitive market. This focus on innovation has enabled Laser Equipment Manufacturers to introduce cutting-edge laser solutions that address the evolving needs of its customers.In addition to its product offerings, Laser Equipment Manufacturers provides comprehensive support and maintenance services to its clients. The company's team of experienced technicians is trained to handle all aspects of installation, training, and technical support, ensuring that customers can maximize the value of their investment in laser technology.As a customer-centric company, Laser Equipment Manufacturers places a strong emphasis on understanding the unique requirements of each client. By taking the time to listen to their customers' needs and challenges, the company is able to tailor its solutions to deliver maximum impact and value. This approach has fostered strong, long-term relationships with a diverse clientele, ranging from small businesses to large multinational corporations.Laser Equipment Manufacturers also values sustainability in its operations. The company actively seeks to minimize its environmental footprint by implementing green manufacturing practices and promoting energy-efficient solutions. This commitment to sustainability not only benefits the environment but also resonates with customers who prioritize responsible business practices.With a global presence, Laser Equipment Manufacturers has established a strong network of partners and distributors to serve customers worldwide. This extensive reach allows the company to efficiently deliver its products and services to a broad range of industries, including automotive, aerospace, electronics, and medical device manufacturing.In light of its continued growth and success, Laser Equipment Manufacturers is poised to further expand its market presence and solidify its position as a leader in the laser technology industry. By consistently delivering cutting-edge solutions and unparalleled customer support, the company is well-positioned to capitalize on the increasing demand for advanced laser equipment.Looking ahead, Laser Equipment Manufacturers remains committed to driving innovation and exceeding customer expectations. The company's relentless pursuit of excellence and its dedication to empowering businesses with the latest laser technology are sure to underpin its continued success in the years to come. As industries continue to embrace the potential of laser technology, Laser Equipment Manufacturers is well-equipped to lead the way with its visionary approach and unwavering commitment to advancing the possibilities of laser applications.

High-Precision Laser Tube Cutting Services for Industrial Applications

Laser Tube Cutting Factory, one of the leading companies in the industry, continues to make strides in innovation and technology with its state-of-the-art facilities and cutting-edge equipment. With a commitment to quality and precision, the factory has established itself as a top choice for customers seeking high-quality tube cutting services.The factory is equipped with the latest laser cutting technology, including advanced fiber laser machines that are capable of cutting a wide range of materials with unparalleled accuracy and speed. Whether it's stainless steel, aluminum, brass, copper, or titanium, the factory has the capabilities to handle the most challenging projects with efficiency and precision.In addition to its cutting-edge equipment, Laser Tube Cutting Factory also prides itself on its team of highly skilled and experienced professionals. The factory employs a team of technicians and engineers who are experts in their field, ensuring that each project is executed with the highest level of expertise and attention to detail. With their extensive knowledge and experience, the team is able to provide innovative solutions to complex cutting challenges, delivering results that exceed customer expectations.The factory's commitment to quality and precision is further exemplified by its adherence to strict quality control measures. Every project undergoes rigorous inspection and testing to ensure that the final product meets the highest standards of quality. This attention to detail has earned the factory a reputation for delivering superior results that consistently outperform the competition.Laser Tube Cutting Factory caters to a wide range of industries, including automotive, aerospace, medical, and architectural, among others. Its diverse client base is a testament to the factory's ability to meet the unique needs of each industry, providing tailored solutions that are both efficient and cost-effective. Whether it's prototype development, large-scale production, or custom fabrication, the factory has the capabilities to handle any project with precision and excellence.In addition to its commitment to quality and precision, Laser Tube Cutting Factory is also dedicated to environmental sustainability. The factory has invested in cutting-edge equipment that minimizes waste and maximizes efficiency, reducing the environmental impact of its operations. By integrating sustainable practices into its manufacturing processes, the factory is able to deliver high-quality results while minimizing its carbon footprint.As the industry continues to evolve, Laser Tube Cutting Factory remains at the forefront of innovation and technology. The factory continuously invests in research and development to further enhance its capabilities and stay ahead of the competition. With a focus on continuous improvement, the factory is well-positioned to meet the evolving needs of its customers and deliver cutting-edge solutions that set new industry standards.With its commitment to quality, precision, and innovation, Laser Tube Cutting Factory has established itself as a trusted partner for customers seeking high-quality tube cutting services. Its dedication to excellence, combined with its advanced technology and experienced team, sets the factory apart as a leader in the industry. Whether it's a small-scale project or a large-scale production, customers can trust Laser Tube Cutting Factory to deliver results that exceed expectations.

Top Fiber Laser Reviews: The Ultimate Guide to Choosing the Right Laser for Your Needs

Fiber Laser Reviews: A Pioneer in Laser TechnologyLaser technology has revolutionized many industries, from medicine to manufacturing, electronics to entertainment. It offers precision, speed, and versatility that cannot be matched by traditional tools or methods. One company that has been at the forefront of laser technology is Fiber Laser Reviews (need to remove brand name), a leader in fiber lasers for cutting, welding, marking, and engraving applications.Fiber Laser Reviews was founded in 2009, with a mission to provide customers with high-quality, reliable, and affordable fiber laser solutions. The company's team of engineers, technicians, and sales professionals has decades of experience in laser technology, and they are committed to delivering exceptional products and services to their clients.Fiber lasers are solid-state lasers that use a fiber optic cable to deliver the laser beam to the workpiece. They offer several advantages over other laser types, such as CO2 or Nd:YAG, including higher efficiency, lower maintenance, smaller footprint, and better beam quality. Fiber Laser Reviews offers a wide range of fiber lasers, from 20W to 200W, with various wavelengths, pulse widths, and beam qualities, to match different applications and materials.One of Fiber Laser Reviews' flagship products is the FL-30 Fiber Laser Cutter, a compact and powerful laser cutting machine that can handle a wide range of materials, including metals, plastics, ceramics, and composites. The FL-30 features a 30W fiber laser source and a cutting area of 300mm x 300mm, with a cutting speed of up to 800mm/s and a positioning accuracy of ±0.03mm. The machine is easy to use, with a user-friendly interface, and it comes with a range of accessories and options, such as a rotary device, a fume extractor, and a camera system.Another popular product from Fiber Laser Reviews is the FM-20 Fiber Laser Marking Machine, a versatile and reliable laser marking system that can mark text, logos, graphics, and barcodes on various surfaces, including metals, plastics, glass, and leather. The FM-20 features a 20W fiber laser source and a marking area of 110mm x 110mm, with a marking speed of up to 7000mm/s and a minimum character size of 0.3mm. The machine supports multiple file formats, such as DXF, PLT, BMP, and AI, and it can be connected to a PC or a laptop via USB or Ethernet.Fiber Laser Reviews also offers a range of fiber laser welders, such as the FW-100 Fiber Laser Welding Machine, a high-performance and cost-effective welding solution for metals and alloys. The FW-100 features a 100W fiber laser source and a welding area of 300mm x 150mm, with a welding speed of up to 60mm/s and a welding depth of up to 2mm. The machine has a built-in microscope and a CCD camera for precise welding control, and it can be customized with various clamping devices and fixtures.Fiber Laser Reviews' products have been widely used in various industries, such as aerospace, automotive, electronics, jewelry, medical, and signage. The company has a global presence, with offices and distributors in North America, Europe, Asia, and Australia, and it has earned a reputation for quality, innovation, and customer satisfaction."We are committed to providing the best fiber laser solutions to our customers, whether they are small businesses or large corporations," said a spokesperson for Fiber Laser Reviews. "We understand the challenges and opportunities of laser technology, and we are always exploring new ways to improve our products and services. We believe that fiber lasers are the future of laser technology, and we are proud to be a pioneer in this field."Fiber Laser Reviews' customers have also praised the company's products and support. "The FL-30 fiber laser cutter has been a game-changer for our sheet metal fabrication business," said a customer from California. "It is fast, accurate, and easy to use, and it has helped us reduce our production times and costs. We are very satisfied with the product and the service we received from Fiber Laser Reviews."In conclusion, Fiber Laser Reviews is a leading provider of fiber laser solutions for cutting, welding, marking, and engraving applications, with a wide range of products, global presence, and excellent customer support. Whether you are a small business or a large corporation, if you are looking for a reliable and affordable fiber laser solution, Fiber Laser Reviews should be on your list.

Powerful 2000w Laser Cutting Machine for Precision Cutting

The latest addition to the cutting-edge technology at the forefront of manufacturing is the 2000w Laser Cutting Machine. This state-of-the-art machine has the capability to revolutionize the way companies approach their cutting and manufacturing processes. With precision and efficiency as its core features, this machine is set to bring a new level of excellence to the manufacturing industry.The 2000w Laser Cutting Machine is a remarkable piece of equipment that delivers high-quality and precise cutting for a wide range of materials. This machine is equipped with advanced laser technology that allows for the cutting of various materials, including metals, plastics, glass, wood, and more. With a maximum power of 2000w, this machine is capable of cutting through materials with ease and precision, making it an ideal choice for industrial manufacturing.One of the key features of the 2000w Laser Cutting Machine is its high-speed cutting capabilities. With its advanced laser technology, this machine is able to cut through materials at a much faster rate than traditional cutting methods. This not only increases efficiency and productivity but also reduces production time, making it a valuable asset for any manufacturing operation.In addition to its speed and precision, the 2000w Laser Cutting Machine is also highly versatile. Its advanced technology allows for a wide range of cutting capabilities, including intricate designs and complex shapes. This level of flexibility opens up a world of possibilities for manufacturers, enabling them to create products that were previously impossible with traditional cutting methods.The company behind this cutting-edge machine is a leader in the manufacturing industry, with a long-standing reputation for excellence and innovation. With a strong focus on research and development, they have consistently delivered cutting-edge solutions to meet the ever-evolving needs of the industry. The 2000w Laser Cutting Machine is the latest addition to their impressive lineup of advanced manufacturing equipment, further solidifying their commitment to delivering the best technology to their customers.The company's dedication to quality and innovation is evident in every aspect of the 2000w Laser Cutting Machine. From its advanced laser technology to its high-speed cutting capabilities, this machine is a testament to the company's relentless pursuit of excellence. With a focus on precision, efficiency, and versatility, this machine is poised to elevate the standards of manufacturing and set new benchmarks for the industry.In conclusion, the introduction of the 2000w Laser Cutting Machine represents a significant milestone in the manufacturing industry. With its advanced technology, high-speed cutting capabilities, and versatile cutting options, this machine is set to revolutionize the way companies approach their manufacturing processes. Backed by a company with a long-standing reputation for excellence and innovation, this machine is a game-changer that is sure to make a lasting impact on the industry.

Revolutionary 3D Fiber Laser Marking Machine Takes Marking to the Next Level

3D Fiber Laser Marking Machine: A Revolutionary Tool for Precise and Efficient MarkingMarking and identification are important tasks in almost every industry, from automotive to aerospace, from electronics to medical devices. The traditional methods of marking, such as mechanical engraving or chemical etching, have limitations in terms of precision, speed, and versatility. However, with the advent of laser technology, a new era of marking has begun. Among the various types of laser marking machines, the 3D Fiber Laser Marking Machine stands out as a powerful and innovative tool for precise and efficient marking of various materials, including metals, plastics, ceramics, and composites.The 3D Fiber Laser Marking Machine (hereafter referred to as “the machine”) is a state-of-the-art device that uses a high-power pulsed laser beam to create permanent marks on the surface of the target material. Unlike traditional marking methods, the machine can produce three-dimensional markings with a high degree of accuracy, resolution, and consistency. The machine can also perform various types of marking, such as text, graphics, images, logos, barcodes, QR codes, and serial numbers, with customizable parameters such as font, size, depth, and orientation.The machine is equipped with a fiber laser source that generates a focused beam of light with a wavelength of around 1064 nm, which is ideal for marking a wide range of materials without causing thermal damage or deformation. The laser beam is guided by a fiber optic cable and directed to the marking head, which contains a galvanometer scanner that can move the beam quickly and precisely in two or three dimensions. The marking head also has a focusing lens that can adjust the beam diameter and focal length to optimize the marking quality. The machine is controlled by a user-friendly software that enables the operator to choose the marking parameters, import the design files, preview the results, and adjust the settings accordingly.The machine has several advantages over other marking methods. Firstly, it is non-contact and non-invasive, which means that it does not deform or damage the material surface. This is particularly important for delicate or complex parts, where mechanical or chemical methods may cause distortion, burrs, or residue. Secondly, it is highly precise and reproducible, which means that it can create identical markings with a tolerance of less than 0.1 mm. This is particularly important for quality control, traceability, and branding, where the consistency and legibility of the markings are paramount. Thirdly, it is fast and efficient, which means that it can mark a large number of parts in a short time, with a cycle time of less than 10 seconds per marking. This is particularly important for high-volume production, where the speed and throughput of the marking process are crucial.The machine has a wide range of applications in various industries, such as:- Automotive: marking of engine components, chassis parts, wheels, and other components for identification, branding, and traceability.- Aerospace: marking of aircraft parts, avionics, and instruments for tracking, safety, and compliance.- Electronics: marking of printed circuit boards, chips, connectors, and housings for identification, serialization, and anti-counterfeiting.- Medical Devices: marking of implants, surgical instruments, and medical equipment for traceability, quality assurance, and patient safety.- Jewelry: marking of precious metals, gems, and watches for branding, certification, and personalization.The machine is developed and manufactured by a leading company (remove brand name) in the field of laser equipment. With years of experience and expertise, (remove brand name) has been committed to providing innovative and reliable solutions for industrial and scientific applications. The machine is a result of extensive research and development, using the most advanced technologies and materials, and tested rigorously to ensure the highest standards of quality and performance.The machine is also backed by a comprehensive service and support system, including installation, training, maintenance, and repair. The company's technicians and engineers are highly trained and knowledgeable, and can assist the customers in every aspect of the machine's operation and maintenance. The company also provides a warranty and a lifelong technical support to ensure the customers' satisfaction and success.The machine is not just a tool, but a solution that can revolutionize the marking process and improve the productivity and profitability of the industries. By using the machine, the customers can achieve the following benefits:- Higher accuracy and consistency of markings, which reduces the risk of errors, rework, and scrap.- Faster cycle time and higher throughput, which increases the production capacity and efficiency.- Lower cost of ownership and maintenance, which saves money and resources in the long-term.- Better quality and reliability of products, which enhances the reputation and competitiveness of the brand.In conclusion, the 3D Fiber Laser Marking Machine is a game-changing technology that can transform the way we mark and identify the products. With its advanced features, benefits, and support, the machine is a must-have asset for the industries that value precision, speed, and versatility in their marking process.

Top Industrial Machine Tools for Your Manufacturing Needs

Industrial Machine Tools is a leading company in the manufacturing and distribution of high-quality machine tools and equipment for various industrial applications. With over 20 years of experience in the industry, Industrial Machine Tools has established itself as a reliable and trusted partner for businesses seeking top-of-the-line machinery to enhance their production processes.The company's extensive product line includes a wide range of machine tools such as lathes, milling machines, drilling machines, grinding machines, and more. Industrial Machine Tools is committed to providing cutting-edge solutions to meet the evolving needs of its customers, delivering both standard and customized machinery tailored to specific requirements.With a team of skilled engineers and technicians, Industrial Machine Tools is dedicated to delivering superior products and services that guarantee optimal performance and reliability. The company's commitment to quality is evident in the meticulous design and construction of its equipment, ensuring precision and efficiency in every operation.In addition to its comprehensive product offering, Industrial Machine Tools also provides expert guidance and support to help businesses make informed decisions about their machinery investment. The company's knowledgeable sales team is always ready to assist customers in selecting the right equipment for their applications, taking into consideration factors such as production volume, material types, and operational requirements.Furthermore, Industrial Machine Tools offers comprehensive maintenance and repair services to ensure that its customers' equipment operates at peak performance. The company's technical experts are equipped with the necessary skills and tools to address any issues promptly, minimizing downtime and maximizing productivity for its clients.Industrial Machine Tools' dedication to customer satisfaction is reflected in its strong emphasis on building lasting relationships with its clients. The company prioritizes open communication and transparent collaboration, striving to address each customer's unique needs and exceed their expectations.Moreover, Industrial Machine Tools is committed to supporting businesses in optimizing their production processes and improving overall efficiency. The company continuously explores the latest technological advancements in the industry, incorporating innovative features and capabilities into its machinery to enhance performance and productivity.The company's unwavering commitment to excellence has earned Industrial Machine Tools a solid reputation as a reliable and respected provider of high-quality machine tools. From small businesses to large-scale industrial operations, the company has established itself as a go-to source for top-tier equipment and exceptional service.Looking ahead, Industrial Machine Tools remains dedicated to advancing the industry and empowering businesses with the tools they need to succeed. The company continuously seeks opportunities to expand its product offerings, enhance its services, and deepen its impact on the industrial landscape.In conclusion, Industrial Machine Tools stands as a trusted partner for businesses looking to elevate their production capabilities with cutting-edge machine tools and equipment. With its unwavering commitment to quality, expert guidance, and comprehensive support, the company is poised to continue making a significant impact in the industry for years to come.

Hot Sale 10W 20W 30W Fiber Laser Marking Machine with CE FDA Certificates Seeking Global Distributors

In today's digital age, marked by rapid technological advancements, entrepreneurs and businesses are constantly seeking innovative ways to enhance product branding and traceability. One such solution that has gained significant traction is the Fiber Laser Marking Machine. With its cutting-edge capabilities, this machine offers precise and permanent marking on a variety of materials, including metals, plastics, rubber, and more. In this blog post, we will explore the features, benefits, and market potential of the DEK-10W/20W/30W/50W Fiber Laser Marking Machine by Jinan Dekcel CNC Equipment Co., Ltd.The DEK Fiber Laser Marking Machine range includes options with power outputs of 10W, 20W, 30W, and an impressive 50W. These machines are equipped with a Fiber Laser Controller that ensures high-precision marking, making them ideal for industrial and commercial applications. The laser marking process delivers permanent and non-contact marking, eliminating the need for consumables such as inks or dyes. The result is a cost-effective and eco-friendly marking solution that offers unmatched durability and resistance to environmental factors.One of the standout features of the DEK Fiber Laser Marking Machine range is its versatility. Regardless of the material, texture, or shape, this machine can mark products with remarkable precision. From intricate artwork and serial numbers to barcodes and logos, the DEK Fiber Laser Marking Machine can handle it all. This versatility makes it an indispensable tool for a wide range of industries, including automotive, aerospace, jewelry, medical, and many more.Furthermore, DEK's Fiber Laser Marking Machines are designed with user-friendliness in mind. The easy-to-use Fiber Laser Controller allows operators to swiftly navigate through settings and customize marking parameters based on their specific requirements. Additionally, the machine's ergonomic design ensures comfortable and efficient operation, minimizing downtime and maximizing productivity. With CE FDA certificates, the DEK Fiber Laser Marking Machines showcase their compliance with international quality and safety standards, further enhancing their appeal to businesses worldwide.As the demand for Fiber Laser Marking Machines continues to grow, businesses aspiring to become distributors of this cutting-edge technology can expect to tap into a highly lucrative market. The versatility, precision, and durability offered by DEK's Fiber Laser Marking Machines make them an attractive proposition to a diverse range of industries. The machines' ability to create permanent and high-quality markings, coupled with their eco-friendly nature and cost-effectiveness, allows businesses to enhance their product value and ensure traceability throughout the supply chain.To succeed as a distributor, it is crucial to build strong relationships with potential customers and raise awareness about the DEK Fiber Laser Marking Machine range. Utilizing effective SEO strategies, such as incorporating target keywords like "Fiber Laser Controller," can significantly improve visibility and generate organic traffic to your online platforms. Creating informative blog content, like this 1000-word blog post, is an excellent way to engage potential customers, educate them about the benefits of Fiber Laser Marking Machines, and position your business as a reliable industry expert.In conclusion, the DEK-10W/20W/30W/50W Fiber Laser Marking Machine range by Jinan Dekcel CNC Equipment Co., Ltd offers an innovative solution for product marking and traceability. With their exceptional precision, versatility, and user-friendly design, these machines have the potential to revolutionize various industries. By becoming a distributor of DEK's Fiber Laser Marking Machines and employing effective SEO strategies, businesses can establish themselves as key players in this expanding market. So, seize this opportunity today and unlock the immense potential these advanced marking machines have to offer.

Powerful Tube Cleaning Machine for Industrial Use

Tube Cleaning Machine Revolutionizing Industrial CleaningIndustrial cleaning is an essential aspect of maintaining the efficiency and safety of various manufacturing and processing plants. One of the key components of industrial cleaning is the maintenance of tubes and pipes that are used in heat exchangers, boilers, condensers, and other industrial equipment. The traditional methods of tube cleaning have often been time-consuming, labor-intensive, and inefficient, resulting in increased downtime and production costs for companies. However, with the introduction of the innovative Tube Cleaning Machine by a leading industrial equipment manufacturer, the landscape of industrial cleaning is set to undergo a significant transformation.The Tube Cleaning Machine, developed by a team of experienced engineers and industry experts at the company, is a cutting-edge solution designed to streamline the process of tube cleaning in industrial settings. Equipped with state-of-the-art technology and advanced features, this machine promises to deliver superior cleaning performance while drastically reducing the time and effort required for the task. Its high-powered cleaning capabilities are especially beneficial for industries such as power generation, oil and gas, petrochemical, and chemical processing, where the maintenance of tubes and pipes is critical for operational efficiency and regulatory compliance.The key highlight of the Tube Cleaning Machine lies in its innovative design and functionality. The machine utilizes a combination of high-pressure water jets, rotation, and suction to effectively remove various types of fouling and deposits from the internal walls of tubes. This automated process not only ensures thorough cleaning but also eliminates the need for manual labor, thereby minimizing the risk of employee exposure to hazardous materials and reducing the overall cleaning time. Furthermore, the machine's adaptability to different tube sizes and materials makes it a versatile solution for a wide range of industrial applications.In addition to its superior cleaning capabilities, the Tube Cleaning Machine is also designed with user convenience and safety in mind. The intuitive control interface and automated operation make it easy for operators to oversee the cleaning process with minimal intervention, while built-in safety features ensure protection against potential hazards. Moreover, the machine's robust construction and durable components guarantee long-term reliability and performance, making it a valuable investment for businesses seeking to enhance their cleaning operations.The impact of the Tube Cleaning Machine on industrial cleaning practices is already being recognized by leading companies in the field. Several organizations have reported significant improvements in operational efficiency, reduced downtime, and cost savings after implementing this advanced cleaning solution. By incorporating the Tube Cleaning Machine into their maintenance routines, industrial facilities can proactively address fouling and deposit buildup, thereby extending the lifespan of their equipment and optimizing their overall production processes.Furthermore, the environmental benefits of the Tube Cleaning Machine cannot be overlooked. By utilizing high-pressure water jets for cleaning, the machine eliminates the need for chemical cleaning agents, thereby reducing the environmental impact of industrial cleaning operations. This aligns with the growing emphasis on sustainable and eco-friendly practices within the industrial sector, further positioning the Tube Cleaning Machine as a future-ready solution for modern manufacturing and processing plants.As the demand for efficient and effective industrial cleaning continues to grow, the Tube Cleaning Machine stands out as a game-changer in the realm of tube and pipe maintenance. Its ability to revolutionize the cleaning process, improve operational performance, and contribute to environmental sustainability makes it a valuable asset for industries worldwide. With ongoing advancements and enhancements, the future of industrial cleaning appears brighter and more streamlined than ever, thanks to the innovative technology embodied by the Tube Cleaning Machine.

Advanced Small Laser Welder for Precision Welding Applications

Small Laser Welder Revolutionizing Precision Welding in Manufacturing IndustryIn today's fast-paced manufacturing industry, precision and efficiency are two key factors that can make or break a company's success. With the increasing demand for high-quality products and the need for faster production times, manufacturers are constantly seeking innovative solutions to enhance their welding processes. This is where the small laser welder comes into play, revolutionizing precision welding in the manufacturing industry.{Company} is a leading provider of advanced laser technology solutions, specializing in cutting-edge laser systems that are designed to meet the needs of modern manufacturing processes. The company has recently introduced a small laser welder that has been making waves in the industry, setting new standards for precision welding and enhancing the efficiency of production lines.The small laser welder is a compact yet powerful tool that is designed to deliver precise and clean welds on a wide range of materials, including metals, plastics, and ceramics. Its advanced laser technology allows for pinpoint accuracy and control, ensuring that every weld is of the highest quality and meets the strictest industry standards.One of the key features of the small laser welder is its versatility. Whether it's joining small parts with intricate geometries or welding delicate components with minimal heat input, this innovative tool is capable of handling a variety of welding tasks with ease. Its compact size also makes it ideal for use in tight spaces and for applications where traditional welding methods may be impractical.Furthermore, the small laser welder offers significant advantages over conventional welding techniques. By utilizing a focused laser beam, it minimizes the heat-affected zone and eliminates the need for additional filler materials, resulting in cleaner and more efficient welds. This not only improves the overall quality of the welding process but also reduces the risk of distortion and material damage.In addition to its precision and efficiency, the small laser welder is also highly cost-effective. Its minimal energy consumption and low maintenance requirements make it a viable long-term investment for manufacturers looking to streamline their welding operations and reduce production costs. Furthermore, its user-friendly interface and intuitive controls make it accessible to operators of all skill levels, eliminating the need for extensive training or specialized expertise.{Company}'s small laser welder is already making a significant impact in the manufacturing industry, with numerous companies adopting this cutting-edge technology to enhance their welding processes. With its unmatched precision, efficiency, and versatility, it is poised to become an indispensable tool for manufacturers seeking to stay ahead of the competition and meet the evolving demands of the market.As the demand for high-quality products continues to grow, the small laser welder is expected to play a vital role in the future of precision welding in the manufacturing industry. Its innovative technology and proven performance are setting new standards for welding efficiency and quality, ultimately reshaping the way manufacturers approach their welding processes.In conclusion, {Company}'s small laser welder represents a significant leap forward in precision welding technology, offering unparalleled accuracy, efficiency, and versatility for manufacturers seeking to elevate their welding processes to new heights. With its advanced laser technology and impressive performance, it is truly revolutionizing precision welding in the manufacturing industry and setting a new standard for excellence.

Powerful Fiber Laser with 6000 W Capability Steals the Spotlight in Latest News

Bystronic Introduces a High-Powered Fiber Laser Cutting Machine Switzerland-based technology leader, Bystronic, has unveiled its latest innovation in the field of laser cutting. Bystronic's all-new Fiber Laser 6000 W is a cutting-edge machine that boasts exceptional power and precision. With its impressive capabilities, this fiber laser cutting system is poised to revolutionize the manufacturing industry.Bystronic is renowned for its commitment to technological advancements and consistently delving into groundbreaking solutions for the manufacturing sector. The introduction of the Fiber Laser 6000 W is a testament to the company's dedication to providing industry-leading cutting solutions. This high-powered laser cutter is designed to optimize efficiency, accuracy, and cost-effectiveness in metal processing.With a power output of 6000 W, this fiber laser machine is capable of handling various types of metals swiftly and effectively. Steel, aluminum, copper, and brass are just some of the materials that can be processed effortlessly by the Fiber Laser 6000 W. By leveraging the latest advancements in fiber laser technology, Bystronic aims to enhance industrial productivity and enable manufacturers to achieve higher levels of precision and flexibility.One of the most striking features of this cutting-edge machine is its ability to cut with exceptional speed and accuracy. By employing Bystronic's state-of-the-art cutting technology, the Fiber Laser 6000 W is capable of achieving clean, precise cuts within seconds. This results in increased productivity and reduced production times, making it an ideal solution for high-volume manufacturing operations.Moreover, the Fiber Laser 6000 W offers enhanced flexibility with its wide range of cutting options. Bystronic's advanced software allows for the creation of intricate and complex designs, allowing manufacturers to make the most of their creativity. The machine's intuitive interface also ensures ease of use, enabling operators to navigate through different features effortlessly.In addition to its exceptional cutting capabilities, the Fiber Laser 6000 W is also designed with efficiency in mind. By implementing energy-saving measures, Bystronic ensures that manufacturers can minimize their environmental footprint while optimizing their production processes. This commitment to sustainability and eco-friendly practices sets Bystronic apart as an industry leader.Bystronic's commitment to providing a comprehensive customer experience is evident in the support and services it offers alongside its cutting-edge machines. The company's global network of service centers guarantees timely assistance, ensuring minimal downtime and uninterrupted production.With the introduction of the Fiber Laser 6000 W, Bystronic reinforces its position as a pioneer in the field of laser cutting technology. By combining technological innovation with exceptional cutting capability, the Fiber Laser 6000 W provides manufacturers with a competitive edge in the global marketplace.As the manufacturing industry continues to evolve, Bystronic remains at the forefront of innovation, constantly striving to meet the ever-changing needs of its customers. The Fiber Laser 6000 W is a prime example of Bystronic's dedication to pushing the boundaries of what is possible in the field of metal processing.In conclusion, Bystronic's Fiber Laser 6000 W is set to revolutionize the manufacturing industry with its exceptional power, speed, and precision. With its ability to handle a wide range of metals and intricate designs, this cutting-edge machine enhances productivity and flexibility while minimizing environmental impact. Bystronic's commitment to customer support further solidifies its position as a leading provider of cutting-edge solutions. With the unveiling of the Fiber Laser 6000 W, Bystronic once again sets a new standard in laser cutting technology, paving the way for a future of innovative manufacturing processes.