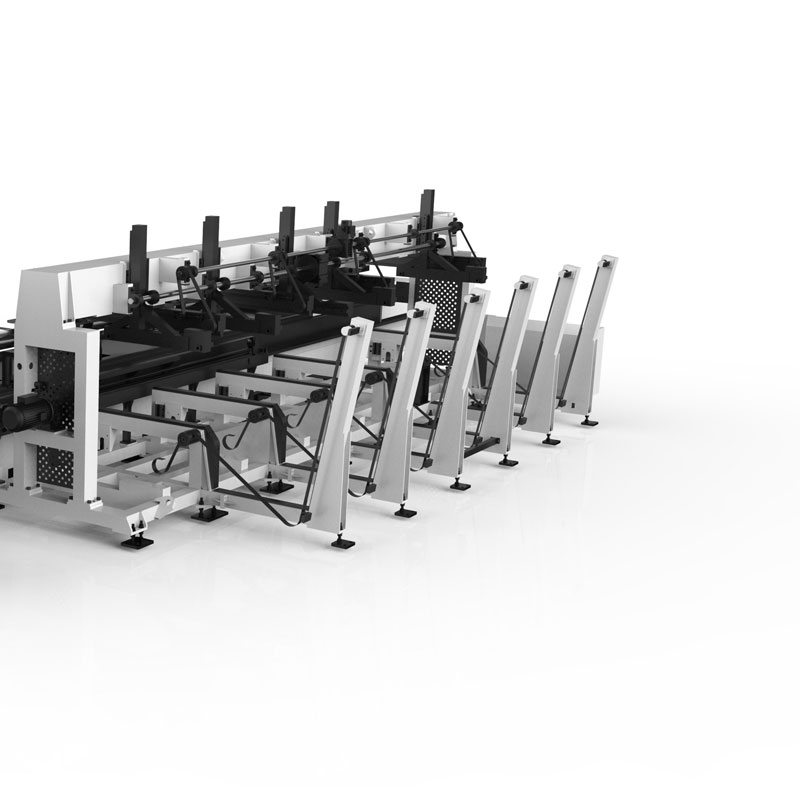

High-Precision Laser Machine Tube for Advanced Industrial Applications

By:Admin

The new laser machine tube is equipped with state-of-the-art technology that allows for faster cutting and engraving, as well as improved accuracy and quality of the end products. With its advanced features, the laser machine tube is capable of processing various materials such as metal, plastic, wood, and glass with utmost precision and speed.

One of the key features of the new laser machine tube is its versatility, allowing users to switch between different modes and settings to accommodate various material thicknesses and types. This makes it an ideal choice for manufacturers who work with a wide range of materials and products.

In addition, the laser machine tube is designed for ease of use and maintenance, with a user-friendly interface that allows operators to set up and control the machine with minimal training. This ensures that businesses can maximize the productivity and efficiency of their laser cutting and engraving processes without the need for extensive technical expertise.

With its high-speed and high-precision capabilities, the new laser machine tube from {Company Name} is expected to significantly enhance the productivity and competitiveness of businesses in the manufacturing and fabrication industries. It will allow them to produce high-quality products with faster turnaround times, ultimately leading to increased customer satisfaction and profitability.

Furthermore, {Company Name} has a strong track record in the laser equipment industry, with a proven commitment to innovation and excellence. The company's team of experts and engineers has a wealth of experience in developing cutting-edge laser technologies, and they have a deep understanding of the needs and challenges faced by businesses in various industries.

{Company Name}'s dedication to customer satisfaction is reflected in their comprehensive customer support and service offerings. They provide ongoing technical support, training, and maintenance services to ensure that their clients can maximize the performance and longevity of their laser equipment.

"We are thrilled to introduce our latest innovation, the new laser machine tube, which is a testament to our ongoing commitment to excellence and innovation in the laser equipment industry," said [Spokesperson's Name], [Job Title] at {Company Name}. "With its advanced features and capabilities, we are confident that the new laser machine tube will empower businesses to take their manufacturing processes to the next level and achieve greater success in their respective industries."

The new laser machine tube from {Company Name} is now available for purchase, and the company is already seeing strong interest and demand from businesses looking to upgrade their laser cutting and engraving capabilities. With its advanced features, high precision, and ease of use, the laser machine tube is expected to set a new standard for the industry, and {Company Name} is proud to be at the forefront of this exciting development.

Company News & Blog

Top Materials for Co2 Laser Cutting: A Comprehensive Guide

Co2 Laser Cutting Materials Revolutionize Manufacturing ProcessesInnovations in the field of manufacturing are constantly evolving and pushing the boundaries of what is possible. One of the latest advancements to take the industry by storm is the use of Co2 laser cutting materials. These materials are revolutionizing the way products are manufactured, offering a level of precision and efficiency that was previously unattainable.Co2 laser cutting materials are a type of material that can be precisely cut and shaped using a high-powered Co2 laser. This technology has been around for several decades, but recent advancements have made it more accessible and versatile than ever before. By harnessing the power of a focused Co2 laser, manufacturers can cut through a wide variety of materials with incredible precision, including metal, plastic, wood, and glass.One company that is at the forefront of this Co2 laser cutting revolution is {}. With a reputation for innovation and quality, {} has been leading the way in the development and implementation of Co2 laser cutting materials. Their state-of-the-art facilities and cutting-edge technology have allowed them to push the boundaries of what is possible in manufacturing, delivering products that exceed industry standards.{} has harnessed the power of Co2 laser cutting materials to streamline their manufacturing processes, offering customers a level of precision and customization that is unmatched in the industry. From intricate metal components to precise plastic parts, {} has demonstrated the versatility and efficiency of Co2 laser cutting materials in a wide range of applications.The benefits of Co2 laser cutting materials are clear. Unlike traditional cutting methods, such as sawing or milling, Co2 laser cutting offers a level of precision that is unmatched. This precision allows manufacturers to create incredibly complex and detailed components with ease, opening up a world of possibilities for product design and innovation.Furthermore, Co2 laser cutting is also incredibly efficient, with the ability to cut through materials at a rapid pace without sacrificing quality. This efficiency not only saves time but also reduces waste, making the manufacturing process more sustainable and cost-effective.The versatility of Co2 laser cutting materials is also a major selling point. Whether working with metal, plastic, wood, or glass, manufacturers can rely on Co2 laser cutting to deliver consistent and high-quality results across a wide range of materials. This versatility makes Co2 laser cutting an attractive option for manufacturers across a variety of industries.With the growing demand for precision and efficiency in manufacturing, it's no surprise that Co2 laser cutting materials are becoming increasingly popular. As more companies, like {}, continue to adopt this technology, we can expect to see even more groundbreaking advancements in the way products are designed and manufactured.For {}, the future of manufacturing is clear. By leveraging the power of Co2 laser cutting materials, they are poised to continue leading the industry in innovation and quality, delivering products that exceed expectations and push the boundaries of what is possible.As the manufacturing industry continues to evolve, it's clear that Co2 laser cutting materials will play a key role in shaping the future of production. With their unmatched precision, efficiency, and versatility, Co2 laser cutting materials are revolutionizing the way products are made, offering manufacturers a level of capability that was previously unimaginable. And with companies like {} leading the way, the possibilities for what can be achieved with Co2 laser cutting materials are truly endless.

Revolutionary Laser Tube Cutting Machine Unveiled in Latest News Content

Title: Revolutionary CNC Laser Tube Cutting Machine Enhances Precision and Efficiency in Industrial ManufacturingIntroduction:In the ever-evolving realm of industrial manufacturing, a groundbreaking innovation has emerged. The advent of CNC (Computer Numerical Control) technology has revolutionized the way components are manufactured, offering unmatched precision and efficiency. One such remarkable CNC machine, the Laser Tube Cutting Machine, is poised to make waves in the industry by providing unparalleled cutting accuracy and versatility. Overview of CNC Laser Tube Cutting Machine:The CNC Laser Tube Cutting Machine represents the apex of manufacturing technology, offering a comprehensive solution for shaping and cutting tubes with uncompromising precision. This cutting-edge machine is equipped with advanced laser technology, controlled by a master computer via a software interface. Its ability to operate autonomously ensures optimal performance and seamless integration into existing manufacturing processes.Precision and Accuracy:The CNC Laser Tube Cutting Machine boasts an outstanding level of precision and accuracy in creating intricate designs across a wide range of materials, including metal, plastic, and composite materials. With laser-guided technology, the machine guarantees consistent perfection, eliminating any human errors that may arise during the traditional cutting process. This precision enables manufacturers to achieve exact specifications while minimizing material waste, reducing costs, and enhancing overall product quality.Versatility and Adaptability:Versatility is a key strength of the CNC Laser Tube Cutting Machine. The machine possesses the ability to cut tubes of various shapes, sizes, and thicknesses, ensuring that it meets the specific requirements of diverse manufacturing projects. The flexibility to work with multiple materials and tube profiles enhances the machine's adaptability, making it an indispensable tool in various industries, including automotive, aerospace, construction, and beyond.Efficiency and Time-Saving:The CNC Laser Tube Cutting Machine streamlines the manufacturing process by significantly reducing production time, which results in improved efficiency and cost-effectiveness. The machine's high-speed laser cutting technology enables manufacturers to swiftly and accurately complete even the most complex tube cutting tasks. By automating the process, the machine minimizes production bottlenecks, allowing manufacturers to meet strict deadlines and increasing overall production capacity.Safety Features:Prioritizing the safety of operators, the CNC Laser Tube Cutting Machine comes equipped with cutting-edge safety features. The machine includes sensor systems that detect any unexpected obstructions or malfunctions, immediately halting the cutting process to prevent accidents and protect the operator's well-being. These safety measures ensure peace of mind and maintain uninterrupted workflow throughout the manufacturing process.Future Possibilities:As the CNC Laser Tube Cutting Machine continues to enhance its capabilities and adaptability, the future prospect for industrial manufacturing looks increasingly promising. The machine's constant evolution promises to overcome current limitations by incorporating advancements such as artificial intelligence and machine learning algorithms. These enhancements propel the industry into the era of smart manufacturing, steadily improving production efficiency and establishing new standards of excellence.Conclusion:The advent of the CNC Laser Tube Cutting Machine heralds a new era in industrial manufacturing, revolutionizing the way components are produced. With its unmatched precision, adaptability, and efficiency, this groundbreaking technology is set to reshape the industry and open doors to limitless possibilities. As more manufacturers embrace this innovative tool, the CNC Laser Tube Cutting Machine will undoubtedly become an indispensable asset, transforming industrial manufacturing processes for years to come.

New metal laser tube technology promises faster and more efficient cutting

Metal Laser Tube Takes the Industry by StormMetal Laser Tube, a laser cutting machine that has been making waves in the industry, is set to revolutionize metal fabrication processes. The machine, developed by a company with decades of experience in the manufacturing of laser cutting machines, is changing the way businesses approach metalworking.One of the key features of the Metal Laser Tube is its use of fiber laser technology, which produces precise cuts at high speeds. This technology has been in use for several years but has gained traction in recent times due to the ease of use and superior results it delivers.Metal Laser Tube can cut through various metals, including copper, brass, aluminum, and stainless steel, to mention a few. Its cutting capabilities are determined by the thickness and type of metal used, but with the right settings, it can cut up to 25mm for steel and 30mm for aluminum.In addition to its impressive cutting abilities, the Metal Laser Tube offers excellent precision and accuracy because of its automated functions. The machine's advanced software allows for customization, ensuring that every piece produced is of impeccable quality. It can also work without human intervention after settings have been input, freeing up time and resources.Another feature that sets the Metal Laser Tube apart from standard laser cutting machines is its long-lasting power source. The fiber laser can last up to 100,000 hours, which translates to around a decade of continuous use, which means businesses can save on maintenance costs and reduce downtime.The machine's compact design also makes it ideal for small and medium-sized businesses with limited space. Its modular design allows for upgrades and customization, allowing businesses to adapt to changes in the industry.Metal Laser Tube is the ideal solution for companies that require precision cutting of metal parts for their products. The machine can deliver results that meet the quality standards of various industries, including automotive, aerospace, and construction.The technology behind Metal Laser Tube has been innovatively developed and refined by an experienced team with over 10 years of experience. The company is determined to raise the bar concerning laser technology by providing cutting-edge solutions that cater to the needs of modern businesses.Since its recent release, Metal Laser Tube has received positive feedback from businesses that have implemented it into their processes. Customers have praised its reliability, durability, and cutting-edge technology, which has helped them save time, resources, and money.In summary, Metal Laser Tube is a game-changing machine that provides cost-effective and efficient solutions for businesses that require precision cutting of metal parts. It's a product of research, innovation, and expertise that is set to revolutionize the metalworking industry. The machine combines cutting-edge technology, smart features, and innovative design, providing a comprehensive solution that meets various industry needs. Metal Laser Tube is the future of metal fabrication, and its impact is set to be felt for years to come.

Ultimate Guide to Laser Tube Cutting Design

Laser Tube Cutting Design Revolutionizes Manufacturing ProcessesIn recent years, the manufacturing industry has seen a significant shift towards the use of advanced technologies to improve production efficiency and product quality. One such technology that has been making waves in the industry is laser tube cutting design. This innovative approach to cutting and shaping tubes and pipes has revolutionized the manufacturing process, allowing for precision and accuracy that was previously unattainable.The introduction of laser tube cutting design has enabled manufacturers to speed up the production process, reduce material waste, and improve the overall quality of the finished products. The technology works by using a high-powered laser to precisely cut and shape tubes and pipes according to specific design requirements. This allows for the creation of complex and intricate designs that would have been extremely difficult, if not impossible, to achieve with traditional cutting methods.One company at the forefront of this technology is {}. With a strong focus on innovation and cutting-edge solutions, the company has been a driving force behind the development and implementation of laser tube cutting design. By leveraging the latest advancements in laser technology and manufacturing processes, {} has been able to offer its customers a range of benefits, including faster production times, improved product quality, and reduced costs.In addition to the technological advancements, {} also places a strong emphasis on customer satisfaction and collaboration. The company works closely with its clients to understand their specific needs and requirements, and then uses its expertise and technology to deliver tailored solutions that meet and exceed expectations. This customer-centric approach has helped {} forge strong and lasting relationships with a wide range of businesses across various industries.One of the key advantages of laser tube cutting design is its ability to handle a wide range of materials, including stainless steel, aluminum, copper, and more. This versatility makes it an ideal solution for manufacturers working with diverse materials and looking to achieve high levels of precision and quality in their products. By using laser tube cutting design, companies can create products that are not only aesthetically pleasing but also highly functional and durable.Another significant benefit of laser tube cutting design is its ability to streamline the production process and reduce material waste. Traditional cutting methods often result in a significant amount of unused or leftover material, leading to increased costs and environmental impact. With laser tube cutting design, manufacturers can minimize waste and maximize the use of materials, ultimately leading to cost savings and a more sustainable approach to manufacturing.Looking ahead, the future of laser tube cutting design looks incredibly promising. As technology continues to advance, we can expect to see even greater levels of precision, speed, and efficiency in the manufacturing process. With companies like {} leading the way in innovation and product development, the industry is poised to undergo a fundamental transformation that will benefit manufacturers and consumers alike.In conclusion, the introduction of laser tube cutting design has had a profound impact on the manufacturing industry, revolutionizing the way tubes and pipes are cut and shaped. With its ability to deliver unmatched precision, versatility, and efficiency, laser tube cutting design has become an essential technology for manufacturers looking to stay ahead of the curve. As the industry continues to evolve, companies like {} will play a crucial role in driving innovation and pushing the boundaries of what is possible in manufacturing.

Advanced Metal Cutting Technology: A Look into the Latest Innovations in Machinery

OEM Metal Cutting Machinery, a leading provider of advanced CNC machining solutions, has recently announced the launch of its latest product offerings. The company, with years of industry experience and innovation, has again proven its expertise in the field by introducing some of the most advanced CNC machines that cater to the modern manufacturing industry.Founded with the vision of providing high quality and innovative metal cutting solutions to customers, OEM Metal Cutting Machinery has carved out its niche in the market with its commitment to excellence. The company prides itself on its ability to build and deliver reliable, advanced, and dynamic CNC machines that match the evolving needs of the industry.With its latest product offerings, the company has reinforced its commitment, bringing in some of the most innovative machines to the market. Speaking about the new product line, a spokesperson for OEM Metal Cutting Machinery said, “We are excited to bring these machines to the market. Our customers demand machines that are efficient, versatile, and able to handle a wide range of tasks, and these machines deliver just that.”The new product line-up brings together state-of-the-art technology and innovative design, enabling users to improve their manufacturing processes and increase productivity. These machines are designed to meet the needs of a variety of industries, including aerospace, automotive, and medical equipment, among others.One of the new products is a 5-axis CNC machine tool that provides an innovative approach to manufacturing. This machine can handle complex part geometries, as well as reduce set-up and lead times. It’s highly suitable for the aerospace and medical industries, where precision and speed are essential requirements.Another product in the new line-up is a CNC lathe that offers enhanced capabilities for achieving precise results. This highly efficient machine provides reduced cycle times, increased accuracy, and high repeatability. It’s designed to handle a variety of materials from aluminum and stainless steel to high-temperature alloys, making it ideal for the automotive and aerospace industries.In addition, the company is also launching a new laser cutting machine that has the ability to cut through a wide range of material thicknesses. This is due to the machine's use of a unique hybrid fiber laser technology that provides excellent cutting results with high quality and precision. The product is ideal for industries that require high-quality cutting, such as the appliance, industrial machinery, and automotive industries.OEM Metal Cutting Machinery's new product line provides a comprehensive range of CNC machining solutions to businesses with unique manufacturing needs. The company’s commitment to innovation and customer satisfaction is evident in these new offerings. Moreover, OEM Metal Cutting Machinery’s machines are known for their high efficiency, reliability, and long service life, delivering great quality and performance in a wide range of applications.Importantly, OEM Metal Cutting Machinery has also built a reputation for providing excellent customer support. The company’s experienced technical and service team is available to help customers with installation, maintenance, and repair. With this commitment to customer service, customers can be confident in the reliability and continued support of their CNC machines.In conclusion, OEM Metal Cutting Machinery's new range of CNC machines provide the latest in advanced technology, precision, and efficiency to companies in various industries. The company's dedication to innovation and customer satisfaction is reflected in these new product offerings - an outstanding example of its OEM digital power.

High-Quality Laser-Cut Steel Plate: The Ultimate Guide

Laser Cut Steel Plate Technology Revolutionizes Manufacturing IndustryIn recent years, the manufacturing industry has experienced a significant evolution in technology, leading to increased efficiency and precision. One of the most notable advancements in this industry is the introduction of laser cut steel plate technology. This cutting-edge technology has revolutionized the way steel plates are processed, allowing for unparalleled accuracy and speed in manufacturing processes.{Company Name} is at the forefront of this technological revolution, offering state-of-the-art laser cut steel plate services to a wide range of industries. With a commitment to innovation and excellence, {Company Name} has established itself as a leader in the field of precision metal fabrication.Laser cut steel plate technology utilizes high-powered lasers to cut through steel with remarkable precision. This advanced method allows for complex shapes and intricate designs to be achieved with absolute accuracy. In addition, laser cutting ensures clean and smooth edges, eliminating the need for additional finishing processes.{Company Name} has invested in cutting-edge laser cutting equipment, allowing them to offer a comprehensive range of steel plate cutting services. Whether for industrial machinery, architectural components, or automotive parts, {Company Name} caters to the diverse needs of their clients with precision and efficiency.The introduction of laser cut steel plate technology has significantly reduced lead times in manufacturing processes. With the ability to cut through thick steel plates at high speeds, {Company Name} is able to deliver orders in a timely manner, meeting even the most demanding deadlines.Furthermore, laser cutting technology has minimized material waste, as it allows for precise nesting and optimization of steel plates. This not only contributes to cost savings for manufacturers but also aligns with sustainable and eco-friendly manufacturing practices.With a team of skilled engineers and technicians, {Company Name} offers personalized support to clients, from the initial design phase to the final production of steel plate components. Their expertise in laser cutting technology ensures that clients receive top-quality products that meet their exact specifications.In addition to their commitment to precision and efficiency, {Company Name} places great emphasis on quality control and safety in their manufacturing processes. Their state-of-the-art facilities are equipped with the latest safety measures, ensuring a secure and controlled environment for laser cutting operations.As a company dedicated to continuous improvement, {Company Name} stays abreast of the latest advancements in laser cutting technology. They regularly invest in training and development, ensuring that their team remains at the forefront of industry trends and best practices.The adoption of laser cut steel plate technology has had a profound impact on the manufacturing industry, offering a level of precision and efficiency that was previously unattainable. {Company Name} has embraced this technology, leveraging it to provide unparalleled cutting services to their clients across various industries.In conclusion, the introduction of laser cut steel plate technology has transformed the manufacturing landscape, and {Company Name} is leading the charge in delivering exceptional precision and efficiency to their clients. With a focus on innovation, quality, and customer satisfaction, {Company Name} remains a trusted partner for all steel plate cutting needs.

Fiber Laser Cutting Machines for Metal – Price, Types and Top Brands

Bodor Laser: Revolutionizing the Metal Cutting Industry with Fiber Laser Cutting MachineBodor Laser is a leading brand in the fiber laser cutting machine industry. Founded in 2008, the company has been at the forefront of producing high-quality and efficient laser cutting machines. With continuous research and development, the company has expanded its product line to other industrial laser cutting solutions such as CO2 laser engraving, marking, and welding machines. The company has its manufacturing facilities in Jinan, China, and has a distribution network that spread over 140 countries. The cutting-edge technology of the Bodor Laser cutting machines has positioned the brand as a market leader. From high precision fiber laser cutting machines to dual-use fiber laser cutting machines and coil laser cutting machines, Bodor Laser has a cutting solution for various applications.One of the notable aspects of Bodor Laser cutting machines is their reliability and efficiency. The machines feature advanced fiber laser technology designed for fast and accurate cutting of different metals, including steel, aluminum, brass, and titanium. The fiber laser cutting machines' processing speed is significantly higher than traditional cutting machines, making them ideal for mass production and sheet metal processing.The fiber laser cutting machine is equally helpful in cutting complex shapes and designs. The machine's exceptional precision allows for producing intricate and detailed cuts, which are not possible with traditional cutting methods. Additionally, Bodor Laser's fiber laser cutting machines have a longer lifespan and require less maintenance, reducing the operating costs. Bodor Laser's innovation is driven by customer satisfaction. The company's customer-centric approach is based on providing cutting-edge solutions that meet customer needs. Bodor Laser's design and production team work closely with clients to understand their specific requirements, making the company a trusted partner in the industry.In addition to the quality of its products, Bodor Laser's customer service is exceptional. The company has a team of trained professionals who offer technical support, training, and installation services. Bodor Laser also provides after-sale services to ensure clients' machines are running at optimal performance.Over the years, Bodor Laser has gained an excellent reputation in the metal cutting industry. Its machines have been recognized for their outstanding performance, quality, and precision. The company has won several awards, including the "China's Top 10 Laser Cutting Machine Brands." Such accolades are a testament to the company's commitment to excellence and customer satisfaction.In conclusion, Bodor Laser has revolutionized the metal cutting industry with its fiber laser cutting machines. The company's cutting-edge technology and exceptional customer service have positioned it as a market leader. Bodor Laser's machines offer reliable and efficient metal processing solutions to various industries, making it a sought-after brand globally.

Revolutionize Your Fabric Cutting Process with Advanced Laser Technology

Fiber Cutting Laser Machine: A Revolutionary Technology for Precision CuttingIn today’s rapidly advancing manufacturing industry, perfection and precision are two things that are required in every process. With the evolution of new technologies, companies seek to obtain the most innovative equipment to overcome shortages and meet ever-increasing demand. One of the most widely used devices in the manufacturing industry is the fiber cutting laser machine. This cutting-edge technology has revolutionized the manufacturing industry by providing unmatched levels of accuracy, precision, and flexibility.Fiber cutting laser machines have proven to be a crucial tool in the metal fabrication process, allowing manufacturers to cut intricate designs in a wide range of materials with unparalleled speed and accuracy. They function by emitting a high-energy beam of light that melts and vaporizes the material being cut, leaving a smooth, clean finish. The technology is not only suitable for precision cutting but also for quick and efficient fabrication.One of the many companies that have taken advantage of this cutting-edge technology is (remove brand name), a world leader in innovative manufacturing solutions. The company has been committed to providing customers with quality solutions for over 30 years and has utilized the latest technologies to do so.The fiber laser cutting machines manufactured by (remove brand name) boasts an impressive cutting speed of up to 200 meters per minute. Unlike traditional cutting technology, the fiber laser machine does not use a blade to cut the material but uses a laser beam to vaporize the material precisely. Due to this precise cutting method, the accuracy of the finished product is unmatched by any other cutting technology.The company has developed a range of fiber laser cutting machines suitable for a wide range of metals such as steel, aluminum, brass, and titanium. This versatility makes their equipment ideal for use in the aerospace, medical, and automotive industries. These industries demand a high level of precision, which the fiber laser machine provides. By melting, instead of cutting through the material, the fiber laser machine achieves a precision that exceeds that of traditional cutting methods.But why should someone choose (remove brand name) fiber laser cutting machines over any other product in the market? The answer lies in their innovative solutions. The company continuously invests in research and development and has, as a result, created a range of fiber laser machines that are faster, more precise, and more affordable than those of their competitors.With several years of experience in the field of manufacturing, (remove brand name) understands the importance of accuracy in their client’s production processes. Their fiber laser machines incorporate the latest technological advancements, allowing manufacturers to work with precision and speed. As their machines have high repeatability, clients know that every product they produce will have the exact specifications, regardless of how complex the design may be.In addition to their precision, their fiber laser machines come with a high level of automation. This automation provides a user-friendly experience, even for those who don’t have experience working with a laser cutting machine. With the automation feature, machine downtime is reduced, giving manufacturers some peace of mind, knowing that they can rely on a machine that is affordable, efficient, and reliable.One of the most significant benefits of using a fiber laser cutting machine, especially one developed by (remove brand name), is that it is eco-friendly. The technology uses less energy to operate; this, combined with their innovative technology, makes it a much more environmentally friendly choice than traditional cutting methods.In conclusion, fiber laser cutting machines have, undoubtedly, revolutionized the manufacturing industry, allowing for efficiency and effectiveness in the fabrication process. With its impressive cutting speeds and unparalleled accuracy, these machines have changed the way that manufacturers approach their production processes. For those seeking a reliable, affordable, and efficient fiber laser cutting machine, (remove brand name) has proven to be a leading provider of innovative manufacturing solutions and an exceptional investment in the manufacturing process.

Top Fiber Laser Source for Your Needs

The Best Fiber Laser Source – Revolutionizing Industrial ApplicationsIn the world of manufacturing and industrial applications, the demand for advanced laser technology has been increasing rapidly. In response to this demand, {Company Name} has developed the best fiber laser source that is set to revolutionize the industry. With its superior performance and cutting-edge features, this fiber laser source is expected to set new standards in precision, efficiency, and reliability.{Company Name} is a leading global provider of innovative laser solutions for a wide range of industrial applications. With a strong focus on research and development, the company is committed to pushing the boundaries of laser technology to meet the evolving needs of its customers. The best fiber laser source is the latest addition to {Company Name}’s portfolio of cutting-edge products, and it promises to deliver unparalleled performance in various industrial settings.One of the key features of this fiber laser source is its exceptional beam quality, which is essential for achieving high precision and accuracy in laser cutting and welding processes. The superior beam quality ensures that the laser energy is delivered to the workpiece with utmost precision, resulting in clean, smooth, and consistent cuts or welds. This level of precision is particularly important for industries such as automotive, aerospace, and electronics, where even the slightest deviation from the intended design can have significant repercussions.Moreover, the best fiber laser source from {Company Name} offers a high degree of stability and reliability, making it an ideal choice for high-volume production environments. The advanced laser technology used in this source ensures that the laser beam remains consistent and predictable over extended periods, thereby minimizing downtime and ensuring continuous operation. This level of reliability is crucial for meeting production targets and maintaining quality standards in industrial settings.In addition to its excellent performance, the best fiber laser source also boasts a high level of energy efficiency, which can result in substantial cost savings for industrial users. The fiber laser technology used in this source is known for its low power consumption and high conversion efficiency, making it an eco-friendly and economical choice for industrial applications. By minimizing energy consumption and maximizing productivity, this fiber laser source aligns with the growing emphasis on sustainability and resource efficiency in the manufacturing industry.Furthermore, {Company Name} has integrated advanced control and monitoring features into its fiber laser source, allowing users to optimize and fine-tune the laser parameters according to their specific requirements. With user-friendly interfaces and intuitive software, operators can easily adjust the laser power, pulse frequency, and other parameters to achieve the desired results. This level of control and flexibility empowers industrial users to tackle a wide range of applications with confidence and precision.To support the deployment and integration of its best fiber laser source, {Company Name} offers comprehensive technical support and training programs to its customers. The company’s team of experts is dedicated to ensuring that users can fully leverage the capabilities of the fiber laser source and maximize its potential in their operations. From installation and calibration to ongoing maintenance and troubleshooting, {Company Name} is committed to providing end-to-end support to its customers.In conclusion, the best fiber laser source from {Company Name} represents a significant advancement in laser technology, offering unparalleled performance, reliability, and efficiency for industrial applications. With its superior beam quality, stability, energy efficiency, and user-friendly features, this fiber laser source is poised to set new benchmarks in precision laser processing. The technological innovation and dedication to customer satisfaction demonstrated by {Company Name} further solidify its position as a leading provider of cutting-edge laser solutions. As industries continue to seek more advanced and reliable laser technology, {Company Name} remains at the forefront of delivering the best fiber laser source to meet their needs.

Tips to Avoid Machine Cutting Errors in Woodworking

Cutting machines have become an essential tool in the manufacturing industry, allowing businesses to cut materials quickly and efficiently. One popular cutting machine is the 1015 machine, which is known for its high precision cuts and versatility. However, even the most skilled operators can encounter problems when using a cutting machine, which can result in failed cuts or damages to the equipment.In this blog, we will discuss common mistakes that operators make when using a cutting machine, how to prevent them, and how to optimize your machine for maximum results.Mistake #1: Incorrect Material SetupOne of the most common mistakes that operators make when using a cutting machine like the 1015 is not setting up the material correctly. It might sound like a simple thing to do, but even a small mistake can cause significant problems. For example, if you don't adjust the material to the machine's specifications, you might end up with uneven or jagged cuts. This can lead to wasted materials and additional time and expenses to fix the errors.To prevent this from happening, make sure you read the manual and familiarize yourself with the machine's specifications. Next, ensure that you have the right tools and clamps to keep the materials securely in place. Finally, double-check the setup before you start cutting to ensure that everything is in the right place.Mistake #2: Using the Wrong BladeAnother common mistake is using the wrong blade for the materials you're cutting. For example, if you're cutting metal, you need a different blade than if you're cutting wood. Using the wrong blade can lead to dullness, chipping, and eventually damage to the machine itself.Before you start cutting, make sure that you have the right blade for the job. Research the blade types, sizes, and thicknesses suitable for the material you're cutting. Ensure that the blade is properly set up and lubricated for smooth and clean cuts.Mistake #3: Insufficient MaintenanceCutting machines require regular maintenance to keep them running at their best. However, many operators neglect this important step, which can cause several problems. For example, unchecked debris can build up and jam the machine, resulting in damage or subpar cuts.To prevent this, make sure that you have a maintenance schedule in place and follow it diligently. Regularly check for debris like sawdust or metal filings and clean the machine's mechanisms. Ensure that all the components are well lubricated and adjust any components that might have shifted or become loose.Mistake #4: Operator ErrorSometimes, the mistakes made when using a cutting machine are not related to the machine itself. Instead, operator error can cause damage, improper cuts, or wasted materials.To prevent this, make sure that you or your operators are well-informed and adequately trained in how to use the machine. Always keep safety in mind and wear protective equipment, such as goggles and gloves. Finally, ensure that the operator is focused and not distracted when using the machine.ConclusionThe Oliver Machinery 1015 Cutting Machine is an excellent tool for businesses looking to increase their efficiency and precision. However, ensuring the machine continues to perform at its best requires careful attention and maintenance. By avoiding common mistakes like incorrect material setups, using the wrong blades, insufficient maintenance, and operator error, you can ensure that your cutting machine works efficiently and delivers optimum results.In summary, whenever you experience problems with a cutting machine, take your time, review the above points, and make any necessary adjustments. Applying these best practices will help you optimize your cutting machine, extend its lifespan, and enjoy the benefits of increased efficiency and profitability in your business.