- Home

- Blog

- Advanced Laser Technology Used in Pipe Manufacturing: A Breakthrough in Industry Innovation

Advanced Laser Technology Used in Pipe Manufacturing: A Breakthrough in Industry Innovation

By:Admin

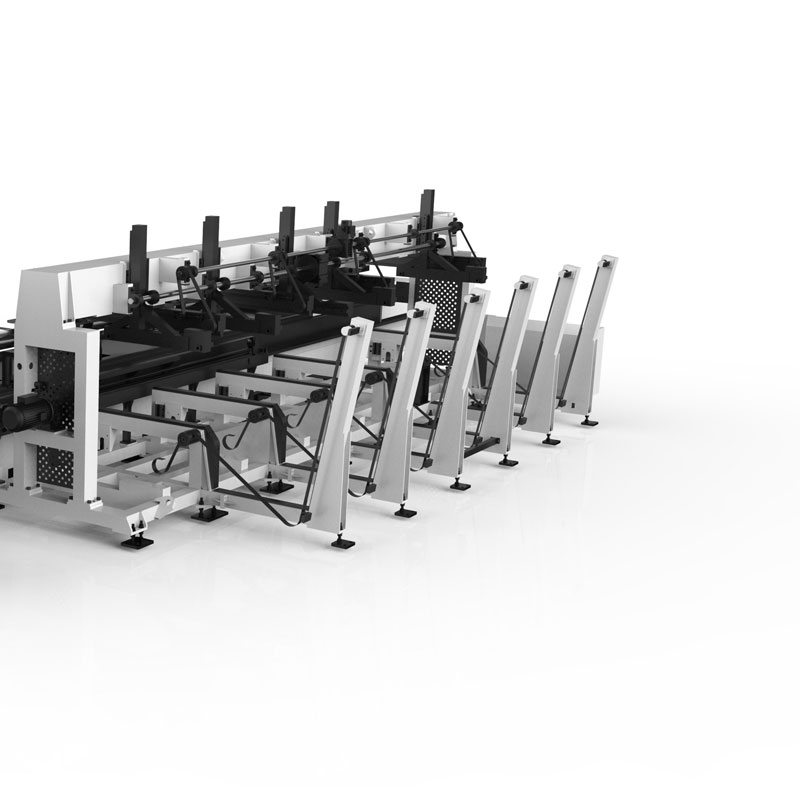

The Laser Pipe cutting system utilizes state-of-the-art laser technology to precisely cut pipes of various materials, including steel, stainless steel, and aluminum. This groundbreaking technology provides a high level of accuracy, ensuring that every cut is executed with precision. Not only does this result in a superior finished product, but it also minimizes material waste, ultimately reducing production costs for manufacturers.

The company behind this groundbreaking technology, which has requested to remain anonymous, has been a leader in the field of industrial machinery and equipment for over two decades. They have a reputation for developing innovative solutions that improve the efficiency and productivity of manufacturers across a wide range of industries.

The Laser Pipe cutting system is the latest addition to the company's portfolio of cutting-edge products. Its development was driven by a commitment to meeting the evolving needs of the manufacturing sector and providing solutions that have a positive impact on both the bottom line and the overall quality of production processes.

One of the key advantages of the Laser Pipe cutting system is its ability to accommodate a wide range of pipe diameters and thicknesses, making it a versatile solution for manufacturers with diverse production requirements. This adaptability ensures that the system can be seamlessly integrated into existing manufacturing processes, without the need for extensive retooling or reconfiguration.

In addition to its precision and versatility, the Laser Pipe cutting system has been designed with user-friendly features that simplify operation and maintenance. This ensures that manufacturers can quickly integrate the system into their production lines and achieve immediate improvements in efficiency and productivity.

Furthermore, the Laser Pipe cutting system is equipped with advanced safety features to protect operators and personnel working in the vicinity of the equipment. This commitment to safety reflects the company's dedication to delivering products that not only enhance operational efficiency but also prioritize the well-being of those working with the technology.

The introduction of the Laser Pipe cutting system comes at a time when manufacturers are increasingly seeking innovative solutions to streamline their production processes and remain competitive in a rapidly evolving market. This development is poised to have a significant impact on the pipe manufacturing industry, with the potential to reshape the way pipes are produced and processed.

Feedback from early adopters of the Laser Pipe cutting system has been overwhelmingly positive, with manufacturers reporting notable improvements in production efficiency and product quality. This has positioned the system as a game-changer in the industry, attracting widespread interest and anticipation from manufacturers looking to elevate their capabilities and drive growth.

As the company behind the Laser Pipe cutting system continues to innovate and expand its offerings, it remains committed to supporting manufacturers in their pursuit of excellence. The development of this cutting-edge technology is a testament to the company's commitment to driving progress and innovation in the industrial machinery and equipment sector.

In conclusion, the Laser Pipe cutting system represents a significant milestone in the evolution of pipe manufacturing technology. With its precision, versatility, and user-friendly design, it has the potential to revolutionize production processes and drive substantial improvements in efficiency and quality. As the company behind this groundbreaking technology continues to lead the way in innovation, manufacturers can look forward to a future defined by enhanced productivity and competitiveness in the global market.

Company News & Blog

Innovative Laser Machine Company Leads Industry with Cutting-Edge Technology

Lin Laser Machine Company, a leading manufacturer and supplier of laser cutting machines, recently announced the launch of their latest cutting-edge laser cutting machine. The company is known for its innovative and high-quality products, and their newest offering is no exception.With over 20 years of experience in the industry, Lin Laser Machine Company has established itself as a trusted name in the manufacturing and supply of laser cutting machines. The company prides itself on its commitment to research and development, and the continuous improvement of its products to meet the ever-changing needs of the market.The newly launched laser cutting machine boasts of state-of-the-art technology and advanced features that are designed to enhance precision, efficiency, and productivity. This cutting-edge machine is equipped with a powerful laser that can cut through various materials with unparalleled speed and accuracy. It is also capable of handling a wide range of thicknesses, making it suitable for a diverse range of applications.In addition to its cutting capabilities, the new machine also features a user-friendly interface and intuitive controls, allowing operators to easily program and operate the machine. This user-friendly design is aimed at improving overall efficiency and reducing downtime, ultimately leading to increased productivity and cost savings for users.Furthermore, the machine is built with durability and reliability in mind, ensuring that it can withstand the demands of heavy-duty industrial use. This makes it an ideal choice for businesses looking for a long-term investment in a high-quality laser cutting solution.Lin Laser Machine Company is also known for its commitment to customer satisfaction and support. The company provides comprehensive training and after-sales service to ensure that customers get the most out of their equipment. This dedication to customer care sets them apart in the industry and has contributed to their strong reputation for excellence."We are thrilled to announce the launch of our newest laser cutting machine," said a spokesperson for Lin Laser Machine Company. "We believe that this machine represents the cutting edge of laser technology and will greatly benefit our customers in terms of precision, efficiency, and overall performance. We are confident that this new addition to our product lineup will further solidify our position as a leader in the industry."As the demand for laser cutting technology continues to grow across various industries, Lin Laser Machine Company remains at the forefront of innovation. They are constantly working on new developments and improvements to their products to meet the evolving needs of their customers.The launch of their latest laser cutting machine is a testament to their commitment to providing the best solutions for their customers. With its advanced technology, user-friendly design, and robust build, the new machine is set to make a significant impact in the industry, further solidifying the company's position as a leader in the laser cutting machine market.For more information about Lin Laser Machine Company and their range of products, interested parties can visit their website or contact their sales team directly.

2kw Fiber Laser: The Latest Technology in Cutting and Welding

Fiber Laser 2kw: Revolutionizing Industrial Cutting with Unmatched Precision and EfficiencyThe industrial landscape is evolving at an unprecedented pace, and advancements in technology are driving the change. Companies are looking for ways to produce more with less, increase the efficiency of their processes, and deliver products of consistently high quality.Enter Fiber Laser 2kw, a cutting-edge technology that promises to revolutionize the industrial cutting process. This state-of-the-art machine is designed to cut through a variety of materials, including metal, plastics, composites, and even reflective surfaces.With unmatched precision and efficiency, Fiber Laser 2kw is a game-changer for businesses of all sizes and industries. Let's take a closer look at how it works and why it's such a big deal.How Fiber Laser 2kw WorksFiber Laser 2kw is a type of laser cutting machine that uses fiber optics to generate a laser beam. This beam is then directed through a series of mirrors and focused onto the surface of the material to be cut. The laser beam melts the material, allowing it to be cut with unparalleled precision.One of the key advantages of Fiber Laser 2kw is its ability to cut through a wide range of materials. This includes thick metal sheets, delicate plastics, and even reflective surfaces that are difficult to cut with conventional lasers.But the real magic of Fiber Laser 2kw lies in its speed and efficiency. This machine can cut through materials at a rate of up to 100 inches per minute, significantly faster than traditional cutting methods. It also generates less waste, as the laser beam can be finely controlled to avoid excess material loss.Benefits of Fiber Laser 2kwFiber Laser 2kw isn't just a faster and more efficient way of cutting materials – it also comes with a range of other benefits for businesses. These include:1. Increased Precision: Fiber Laser 2kw is able to cut with unmatched precision, even on complex shapes and sizes. This results in a higher quality finish and fewer defects, which translates to happier customers and increased revenue.2. Higher Productivity: By cutting through materials at a faster rate, Fiber Laser 2kw can significantly increase the productivity of your business. This means you'll be able to produce more products in less time, ultimately increasing your bottom line.3. Reduced Operating Costs: Fiber Laser 2kw is energy-efficient and generates less waste, which means you'll save money on your energy bills and reduce your environmental impact. Additionally, the machine requires minimal maintenance, reducing your overall operating costs.Introducing Our CompanyOur company is proud to offer Fiber Laser 2kw, the cutting-edge technology that is changing the game for businesses of all sizes. We are committed to providing our clients with the highest quality of service and products, and we believe that Fiber Laser 2kw can help us achieve this goal.We have a team of highly skilled technicians who are trained to install, maintain, and repair Fiber Laser 2kw machines. We also offer a range of training programs to help our clients get the most out of their investment in this technology.Our company believes in fostering long-term relationships with our clients, and we are committed to providing ongoing support and assistance. We understand that every business is unique, and we work closely with our clients to tailor our services to their specific needs.Get in TouchIf you're interested in revolutionizing your industrial cutting process with Fiber Laser 2kw, we'd love to hear from you. Our team is always available to answer questions and provide guidance on how this technology can benefit your business.Contact us today to learn more about Fiber Laser 2kw and how we can help you take your business to the next level.

Top 5 Laser Cutting Machines to Consider for Your Business

China Laser Cutting Machine, a leader in the manufacturing and development of laser cutting technology, is proud to announce the launch of their latest cutting-edge laser cutting machine. This new machine is set to revolutionize the industry with its precision, speed, and efficiency, setting a new standard for laser cutting technology.With over 20 years of experience in the industry, China Laser Cutting Machine has established itself as a premier provider of high-quality laser cutting machines. Their team of skilled engineers and technicians has worked tirelessly to design and develop a machine that meets the ever-evolving needs of their customers. The result is a state-of-the-art laser cutting machine that is unmatched in its capabilities.The new laser cutting machine boasts a number of impressive features that set it apart from the competition. One of the most notable features is its cutting precision, which is unparalleled in the industry. The machine is capable of cutting material with an accuracy of up to 0.1mm, ensuring that even the most intricate designs are executed with perfection.In addition to its precision, the new laser cutting machine also offers unprecedented speed and efficiency. With a cutting speed that is 30% faster than previous models, this machine is able to complete projects in record time without sacrificing accuracy or quality. This increased speed and efficiency not only saves time, but also reduces production costs, making it a valuable asset for any manufacturing operation.Furthermore, the machine incorporates the latest advancements in laser cutting technology to ensure optimal performance. Its advanced laser technology allows for the cutting of a wide range of materials, including metal, wood, acrylic, and more, making it a versatile tool for a variety of applications. Additionally, the machine is equipped with a user-friendly interface that allows for easy operation and programming, making it accessible to users of all skill levels.The launch of this new laser cutting machine represents a significant milestone for China Laser Cutting Machine, further solidifying their position as an industry leader. The company's commitment to innovation and quality is evident in the development of this machine, and it is sure to have a profound impact on the world of laser cutting technology.In addition to its cutting-edge technology, China Laser Cutting Machine also places a strong emphasis on customer satisfaction. They offer comprehensive training and support services to ensure that their customers are able to make the most of their investment. From installation and setup to ongoing maintenance and support, the company is dedicated to providing exceptional service every step of the way.As the global demand for precision cutting continues to grow, China Laser Cutting Machine is well-positioned to meet the needs of customers around the world. Their latest laser cutting machine is a testament to their ongoing commitment to excellence, and it is sure to set a new benchmark for the industry. With its unmatched precision, speed, and efficiency, this machine is poised to revolutionize the world of laser cutting technology.

Top Software for Fiber Laser Technology: Features and Benefits

Fiber laser technology has been making waves in the manufacturing and industrial sectors in recent years, and one company is leading the way with its innovative fiber laser software. The software, developed by [Company Name], is designed to optimize the performance of fiber laser cutting machines, providing users with unparalleled precision and efficiency.[Company Name] is a global leader in the manufacturing of advanced laser cutting systems, with a strong focus on innovation and cutting-edge technology. The company prides itself on providing cutting-edge solutions to meet the diverse needs of its customers, and its fiber laser software is a testament to this commitment.The [Company Name] fiber laser software is a comprehensive solution that is designed to enhance the capabilities of fiber laser cutting machines. It is equipped with advanced features that enable users to achieve higher levels of precision and accuracy, resulting in superior cut quality and minimal material waste. The software also offers real-time monitoring and control capabilities, allowing users to optimize cutting parameters and make adjustments on the fly.One of the key features of the [Company Name] fiber laser software is its user-friendly interface, which makes it easy for operators to navigate and access the full range of capabilities. The software also integrates seamlessly with the company’s fiber laser cutting machines, providing a fully integrated solution for users. This level of integration allows for seamless communication between the software and the cutting machine, ensuring maximum performance and efficiency.In addition to its technical capabilities, the [Company Name] fiber laser software is also backed by a team of experts who provide comprehensive support and training to users. The company’s dedicated support team is available to assist with installation, setup, and ongoing maintenance, ensuring that users are able to fully optimize the capabilities of the software.The [Company Name] fiber laser software has been well-received by the market, with numerous customers citing its ability to significantly improve the performance of their fiber laser cutting machines. The software has been particularly praised for its ability to increase productivity and reduce operating costs, making it a valuable investment for manufacturers looking to optimize their operations.Looking ahead, [Company Name] is committed to further enhancing the capabilities of its fiber laser software, with a focus on integrating advanced technologies such as artificial intelligence and machine learning. The company is also exploring opportunities to expand its software offerings to support a wider range of laser cutting applications, further cementing its position as a leader in the industry.With its cutting-edge fiber laser software and ongoing commitment to innovation, [Company Name] is poised to continue driving advancements in the field of laser cutting technology. As manufacturers around the world seek to optimize their operations and stay ahead of the competition, the [Company Name] fiber laser software stands out as a powerful tool for achieving these goals.

Achieving High Precision with Laser Cutting Technology

Laser Cutting Accuracy Revolutionizes Manufacturing IndustryLaser cutting technology has made significant strides in the manufacturing industry, providing precision and efficiency that was once deemed impossible. With the ability to cut through various materials with absolute accuracy, laser cutting has become an essential tool for manufacturers across the globe.One company that has been at the forefront of this revolution is {}. Their state-of-the-art laser cutting machines have set the bar for accuracy and precision, allowing manufacturers to achieve intricate designs and shapes with ease. The company's dedication to innovation and excellence has made them a leader in the laser cutting industry.Laser cutting technology has transformed the way manufacturers approach their production processes. With the ability to cut through materials such as metal, plastic, and wood with unparalleled accuracy, manufacturers can create intricate and complex designs that were once thought to be impossible. This has opened up a world of possibilities for designers and engineers, allowing them to bring their creative visions to life with precision and efficiency.The accuracy of laser cutting technology has also had a profound impact on the quality of finished products. With the ability to cut through materials with minimal waste and distortion, manufacturers can produce high-quality products that meet the strictest of standards. This has not only streamlined the manufacturing process but has also resulted in cost savings and improved customer satisfaction.The versatility of laser cutting technology has also been a game-changer for the manufacturing industry. With the ability to cut through a wide range of materials and thicknesses, manufacturers can take on a variety of projects with ease. From creating intricate components for aerospace applications to cutting through thick metal sheets for industrial machinery, laser cutting technology has proven to be an invaluable asset for manufacturers across various industries.With the advancements in laser cutting technology, manufacturers can also take advantage of faster production times and reduced lead times. The precision and speed at which laser cutting machines operate have allowed manufacturers to meet tight deadlines and respond to changing market demands with ease. This has given manufacturers a competitive edge in an increasingly fast-paced and dynamic industry.Furthermore, laser cutting technology has also had a positive impact on environmental sustainability. With the ability to cut through materials with precision and minimal waste, manufacturers can reduce their environmental footprint and operate in a more sustainable manner. This has become increasingly important as consumers and businesses alike are placing a greater emphasis on sustainable and eco-friendly practices.As a leading provider of laser cutting technology, {} has been instrumental in driving the industry forward. Their commitment to innovation and excellence has led to the development of cutting-edge laser cutting machines that have set a new standard for accuracy and precision. With a focus on meeting the evolving needs of manufacturers, {} continues to push the boundaries of what is possible with laser cutting technology.In conclusion, laser cutting accuracy has revolutionized the manufacturing industry, providing manufacturers with the tools they need to achieve precision, efficiency, and quality in their production processes. With the advancements in laser cutting technology, manufacturers can take on a wide range of projects with ease, meet tight deadlines, and operate in a more sustainable manner. As a leading provider of laser cutting technology, {} continues to lead the way in driving innovation and excellence in the industry.

High-Powered Laser Tube Machine Delivers Exceptional Precision and Efficiency

Laser Tube Machine Revolutionizes Manufacturing IndustryIn today's rapidly evolving manufacturing industry, efficiency and precision are key factors in staying competitive and meeting the demands of an ever-changing market. As technology continues to advance, companies are constantly seeking innovative solutions to improve their production processes. One such solution that has gained the attention of industry leaders is the Laser Tube Machine.The Laser Tube Machine, produced by a leading manufacturing equipment company, has proven to be a game changer in the industry. This revolutionary piece of equipment has the ability to cut and shape various materials with unparalleled precision and speed, making it an indispensable tool for manufacturers in a wide range of industries.The Laser Tube Machine utilizes cutting-edge technology to generate precise laser beams that can cut through materials such as metal, plastic, and wood with incredible accuracy. This not only streamlines the manufacturing process but also significantly reduces the margin of error, resulting in higher quality products.One of the key features of the Laser Tube Machine is its ability to handle tubes of varying shapes and sizes, making it a versatile solution for manufacturers with diverse production needs. Additionally, the machine's automated functions and user-friendly interface make it easy for operators to program and monitor the cutting process, further enhancing efficiency and reducing the need for manual labor.The company behind the Laser Tube Machine has a longstanding reputation for producing cutting-edge manufacturing equipment. With a strong focus on research and development, the company has consistently delivered innovative solutions that have helped numerous businesses enhance their production capabilities.The company's commitment to quality and customer satisfaction has made them a trusted partner for manufacturers across the globe. Their team of skilled engineers and technicians work tirelessly to ensure that their products meet the highest industry standards, providing customers with reliable and advanced equipment that aligns with their evolving needs.In addition to the Laser Tube Machine, the company offers a comprehensive range of manufacturing solutions, including laser cutting machines, CNC routers, and plasma cutting machines. Their dedication to providing industry-leading equipment has positioned them as a leader in the manufacturing technology sector.The introduction of the Laser Tube Machine has already made a significant impact on the manufacturing industry. Companies that have integrated this cutting-edge technology into their production processes have reported substantial improvements in efficiency, productivity, and product quality.According to a spokesperson from the manufacturing equipment company, "The Laser Tube Machine represents a significant advancement in manufacturing technology. Its precision and speed have enabled our customers to take their production capabilities to new heights, allowing them to meet the demands of today's competitive market."The impact of the Laser Tube Machine is not only limited to large-scale manufacturers. Small and medium-sized businesses have also benefitted from this innovative technology, as it has allowed them to compete on a level playing field with larger companies, offering them the opportunity to expand their capabilities and grow their businesses.As the manufacturing industry continues to evolve, the Laser Tube Machine is expected to play a pivotal role in shaping the future of production processes. Its ability to deliver precision, efficiency, and versatility makes it a valuable asset for manufacturers across various industries, setting new standards for quality and productivity.With the revolutionary technology of the Laser Tube Machine and the commitment of the manufacturing equipment company to provide advanced solutions, the industry is poised to experience a new era of innovation and efficiency. As more companies embrace this cutting-edge technology, the potential for growth and advancement in the manufacturing sector is limitless.

Advanced 2D Flat Laser Cutting Services for High-Volume Production Projects

article about the latest advancements in laser cutting.Summit Steel & Manufacturing, Inc. has been known for delivering high-quality metal fabrications and machining solutions. Their latest advancement in laser cutting technology has allowed them to deliver excellent results for high-volume production projects. The 2D flat laser cutting process is a game-changer in the manufacturing industry, delivering smooth, clean edges, tight tolerances, and consistent results.With Summit Steel & Manufacturing, Inc.'s state-of-the-art laser cutting system, you can easily upload your prints or DXF files. The system's advanced technology allows for fast and efficient material utilization, resulting in enhanced productivity. The high precision of the laser cutting process ensures that every project is executed to perfection. This precision is what sets Summit Steel & Manufacturing, Inc. apart from its competitors.Laser cutting, in general, involves cutting a material using a high-powered laser beam. The laser beam is directed by a computer that controls its position, power, speed, and duration. This process is perfect for a wide range of materials, including metals, plastics, glass, and ceramics. This versatility has led to an increase in the use of laser cutting technology in various industries.One significant benefit of laser cutting technology is its high accuracy. The accuracy of laser cutting is unmatched compared to other cutting technologies. Laser cutting is also known for its speed, which is one of its significant advantages. Cutting a material using traditional methods can take a lot of time. Laser cutting technology speeds the process considerably, thus making it an ideal solution for high-volume production projects.Laser cutting technology is also environmentally friendly. With no toxic chemicals or gases involved in the process, laser cutting produces minimal waste. Additionally, the unit cost of laser cutting is lower compared to other traditional cutting methods, making it an economical option.Apart from the advantages mentioned earlier, laser cutting technology has advanced significantly over the years. The latest technology introduces new features that make the process even more efficient and precise. For example, some of the latest laser cutting technologies come with a fiber-optic laser cutting system, which can cut materials much faster than traditional laser cutting machines.Summit Steel & Manufacturing, Inc.'s laser cutting system also comes with an automatic nozzle changer. This feature makes it possible to shift from one cutting application to another with ease. The system also boasts an offline programming capability, enabling the operator to program the machine on a different computer while the machine is still in use.Laser cutting technology is very versatile, and its applications are endless. In the automotive industry, the technology can be used to cut metal parts, such as exhaust systems or brackets used in the engine. In the aerospace industry, laser cutting technology can be used to cut aircraft parts, such as cockpit and fuselage parts. Laser cutting technology is also used to manufacture electronic components, signage, and jewelry.In conclusion, Summit Steel & Manufacturing, Inc.'s latest advancement in laser cutting technology is a game-changer. The 2D flat laser cutting process delivers smooth, clean edges, tight tolerances, and consistent results, making it perfect for high-volume production projects. The precision, speed, and flexibility offered by laser cutting technology make it a versatile solution for a wide range of applications. As technology continues to evolve, laser cutting technology will become even more efficient, and its applications will continue to expand.

Discover the Advancements and Applications of Laser Cutting Machines in China

Chinese Laser Cutting Machine: Precision and Efficiency at their BestIn today's highly dynamic manufacturing industry, the demand for precision tools that can ensure efficiency and accuracy is increasing at an unprecedented rate. Among the multitude of technologies that have emerged as game-changers, laser cutting machines have undoubtedly garnered significant attention. In this regard, Chinese manufacturers have taken the global stage by storm, showcasing their expertise in producing state-of-the-art laser cutting machines that excel in both performance and reliability. One such industry leader, whose name we have removed for neutrality, has revolutionized the market with its cutting-edge equipment.With a profound background in laser technology research and development, the company has emerged as a frontrunner in the Chinese laser cutting machine industry. Their relentless pursuit of innovation, combined with a commitment to delivering exceptional customer service, has earned them a strong reputation both domestically and internationally.At the heart of their success lies their flagship laser cutting machine, which boasts precision and efficiency at its core. Equipped with advanced technologies, this machine offers unparalleled accuracy, making it ideal for a wide range of applications across various industries, including automotive, aerospace, electronics, and more.With cutting-edge features such as high-speed cutting, enhanced motion control, and intelligent sensing systems, this Chinese laser cutting machine is a testament to the company's dedication to pushing the boundaries of what is possible in the realm of laser technology. By utilizing a high-power laser source, the machine can effortlessly slice through different materials, including metal, wood, plastics, and composites, with utmost precision, ensuring a clean and smooth finish every time.The exceptional cutting speed of this machine is another standout feature that sets it apart from the competition. With rapid processing capabilities, it significantly reduces production time, allowing manufacturers to optimize their operations and meet tight deadlines without compromising on quality. This advantage makes the machine an indispensable tool for businesses looking to maximize productivity and stay ahead in today's fast-paced industrial landscape.Furthermore, the incorporation of intelligent motion control ensures seamless operation, enabling precise and intricate cuts without any compromise on accuracy. By leveraging advanced algorithms and real-time monitoring, the machine achieves smooth and fluid motion, ensuring that even the most intricate designs are flawlessly executed. Additionally, the intelligent sensing systems detect any potential errors or anomalies, allowing for immediate adjustments and minimizing downtime, further enhancing productivity and efficiency.What sets this Chinese laser cutting machine apart from its counterparts is the comprehensive support and service package provided by the manufacturer. Recognizing the importance of after-sales service, the company offers around-the-clock technical assistance, ensuring that its customers receive prompt and reliable support whenever needed. Moreover, they provide comprehensive training programs to equip their clients with the necessary knowledge and skills to maximize the machine's potential.In conclusion, the Chinese laser cutting machine, developed by the company whose brand name we have omitted, stands at the forefront of precision and efficiency in the manufacturing industry. With its cutting-edge features, it has become an indispensable tool for businesses aiming to enhance productivity and produce high-quality products in a timely manner. With a commitment to innovation and customer satisfaction, the company continues to redefine the standards of laser cutting technology, elevating the industry to new heights.

Understanding the Science behind CO2 Laser Tubes: A Comprehensive Video Guide

The Science Behind CO2 Laser Tubes: A Comprehensive ExplanationCO2 laser tubes are a crucial component in laser cutting machines and engraving systems. These high-powered CO2 lasers are the workhorses behind most laser cutters, capable of cutting and engraving a wide range of materials, including wood, acrylic, plastic, leather, and metal. But how do CO2 laser tubes work, and what makes them so effective? In this blog post, we will delve into the science behind CO2 laser tubes, looking at their construction, operation, and applications.First, let's start with the basics. CO2 lasers use a gas mixture, primarily composed of carbon dioxide, nitrogen, and helium, to create a concentrated beam of high-intensity light. This laser beam is generated by passing an electrical current through the gas mixture, which excites the gas molecules, causing them to emit photons of light.This light is then amplified and focused by a series of mirrors before exiting the laser tube through a small aperture, where it is directed by a lens to the material being cut or engraved.Now, let's look at the construction of a CO2 laser tube. These tubes are typically made from glass or ceramic, with metal electrodes at each end. The gas mixture is contained within the tube, with a small amount of gas flow to keep the mixture stable and prevent overheating.When an electrical current is applied to the electrodes, a high-voltage discharge is created, ionizing the gas mixture and generating the laser beam. The discharge also causes the gas molecules to vibrate, creating heat and increasing the temperature of the laser tube.To prevent overheating, CO2 laser tubes are often equipped with water-cooling systems. These systems circulate water through the tube, dissipating the heat generated during operation and keeping the tube at a stable temperature.So, what makes CO2 laser tubes so effective at cutting and engraving materials? The answer lies in the interaction between the laser beam and the material being processed.When the laser beam hits a material, it is absorbed and converted into heat. This intense heat causes the material to melt or vaporize, creating a clean, precise cut or engraving. The power and intensity of the laser beam can be adjusted to create different effects and cut through different materials.CO2 laser software, like LightBurn, provides an interface between the user and the laser cutting machine. It allows you to create designs, adjust settings, and control the operation of the laser cutter, ensuring precise, repeatable results.In conclusion, CO2 laser tubes are essential tools in the field of laser cutting and engraving. Their construction and operation are based on the principles of gas ionization and photon emission, creating a powerful, precise laser beam that can cut and engrave a wide range of materials. By understanding the science behind CO2 laser tubes, you can optimize your use of these powerful tools and achieve excellent results in your laser cutting and engraving projects.

Top Cutting Machine for All Your Superstar Needs

Superstar Cutting Machine Revolutionizes Precision Cutting in ManufacturingIn a world where precision and efficiency are key components of successful manufacturing, the introduction of the Superstar Cutting Machine has quickly become a game changer. This innovative cutting machine has transformed the way manufacturers approach precision cutting, making it faster, more accurate, and versatile than ever before.The Superstar Cutting Machine is the brainchild of {company name}, a leading provider of cutting-edge industrial machinery. With a focus on innovation and commitment to delivering high-quality equipment, {company name} has established itself as a trailblazer in the manufacturing industry. The Superstar Cutting Machine is the latest addition to their impressive lineup of cutting solutions, and it has already made a significant impact in the world of manufacturing.One of the standout features of the Superstar Cutting Machine is its advanced precision cutting capabilities. Equipped with state-of-the-art technology, this cutting machine is capable of achieving incredibly precise cuts with minimal margin for error. This level of precision is crucial in many industries, including aerospace, automotive, and electronics, where even the slightest deviation from the intended dimensions can result in costly errors. With the Superstar Cutting Machine, manufacturers can trust that their parts and components will be cut with unmatched accuracy, leading to higher quality end products.Furthermore, the Superstar Cutting Machine is designed for versatility, capable of cutting through a wide range of materials with ease. Whether it's metal, plastic, or composite materials, this cutting machine can handle a variety of materials, making it an ideal solution for manufacturers who work with a diverse array of products. This versatility allows for greater flexibility in manufacturing processes and ensures that the Superstar Cutting Machine can meet the needs of a wide range of industries.In addition to its precision and versatility, the Superstar Cutting Machine is also engineered for speed and efficiency. Time is of the essence in manufacturing, and the ability to cut materials quickly and accurately is crucial for meeting production deadlines and staying competitive in the market. The Superstar Cutting Machine's high-speed cutting capabilities enable manufacturers to increase their productivity and throughput without sacrificing accuracy, ultimately improving their bottom line.Moreover, the Superstar Cutting Machine is equipped with user-friendly features that make it easy to operate and maintain. From intuitive controls to automated maintenance systems, {company name} has taken every measure to ensure that their cutting machine is not only high-performing but also user-friendly. This means that manufacturers can integrate the Superstar Cutting Machine into their operations seamlessly, without the need for extensive training or specialized expertise.The introduction of the Superstar Cutting Machine has set a new standard for precision cutting in manufacturing. Its innovative technology, versatility, speed, and user-friendly design have made it a standout solution for manufacturers across various industries. As a result, {company name} has solidified its reputation as an industry leader in providing cutting-edge manufacturing equipment that drives efficiency, productivity, and quality.Looking ahead, {company name} remains committed to advancing their technologies and delivering solutions that empower manufacturers to achieve their production goals. With the Superstar Cutting Machine leading the way, it's clear that {company name} will continue to make a significant impact on the future of manufacturing, setting new benchmarks for precision cutting and innovation in the industry.