Top Metal Cutting Machinery for OEM Applications

By:Admin

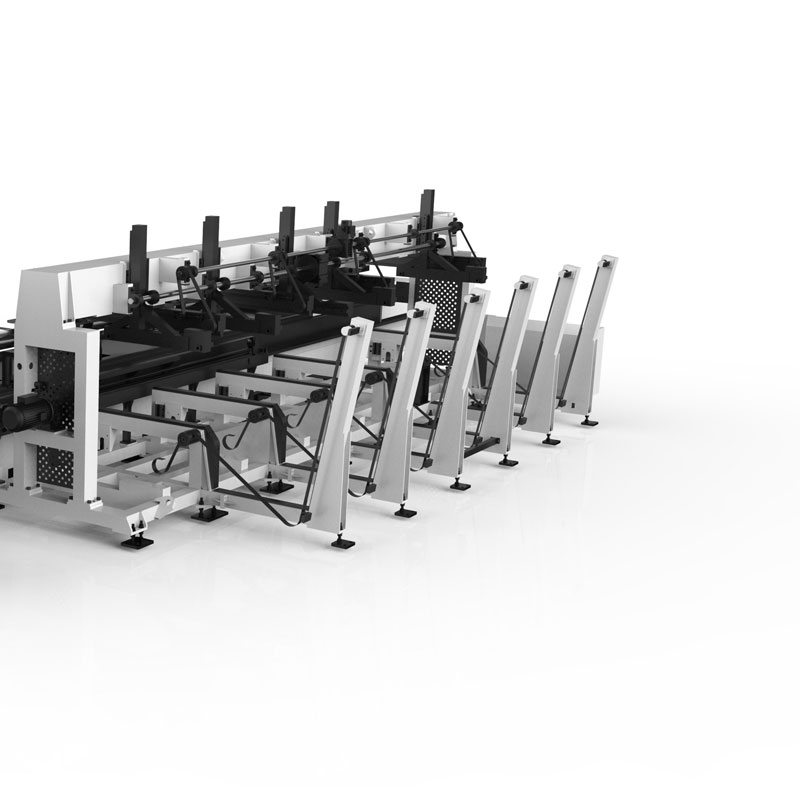

OEM Metal Cutting Machinery offers a wide range of cutting machinery, including CNC plasma cutting machines, laser cutting machines, waterjet cutting machines, and more. These state-of-the-art machines are designed to deliver precision, efficiency, and reliability, making them an ideal choice for a variety of metal fabrication applications.

One of the key factors that sets OEM Metal Cutting Machinery apart from its competitors is its commitment to customized solutions. The company understands that every customer has unique needs and requirements, and they work closely with clients to design and build machinery that meets their specific specifications. This personalized approach has helped OEM Metal Cutting Machinery to build long-lasting relationships with its customers and establish a loyal client base.

In addition to its cutting machinery, OEM Metal Cutting Machinery also provides comprehensive support services to ensure that customers can maximize the performance of their equipment. From installation and training to maintenance and repairs, the company's team of skilled technicians is available to provide assistance whenever it is needed.

Recently, OEM Metal Cutting Machinery has introduced a new line of cutting machinery that incorporates the latest technological advancements. These new machines boast enhanced speed, accuracy, and automation, providing customers with even greater productivity and cost-efficiency. With the global manufacturing landscape becoming increasingly competitive, OEM Metal Cutting Machinery understands the importance of staying ahead of the curve and continuously improving its product offerings.

In response to the growing demand for sustainable manufacturing solutions, OEM Metal Cutting Machinery has also been focusing on developing environmentally-friendly cutting machinery. The company is committed to reducing its carbon footprint and helping its clients to minimize their environmental impact. By integrating energy-efficient technologies and sustainable manufacturing practices, OEM Metal Cutting Machinery is contributing to a greener and more sustainable future for the industry.

Despite the challenges posed by the COVID-19 pandemic, OEM Metal Cutting Machinery has maintained its commitment to delivering exceptional products and services to its customers. The company has implemented strict health and safety measures to ensure the well-being of its employees and continued to support its clients through these difficult times. As the manufacturing sector gradually rebounds, OEM Metal Cutting Machinery is poised to play a key role in driving the industry's recovery and growth.

Looking ahead, OEM Metal Cutting Machinery remains focused on expanding its product portfolio, exploring new market opportunities, and strengthening its position as a leader in the metal cutting machinery industry. With its unwavering dedication to innovation, quality, and customer satisfaction, the company is well-positioned to continue its success and make a lasting impact in the global manufacturing landscape.

Company News & Blog

Advanced Laser Machinery for Cutting and Marking Applications

and Laser Cutting Machine.When it comes to precision and accuracy, laser technology has always been the go-to choice for many industries. Suzhou Suntop Laser Technology Co., Ltd., a high-tech modern enterprise specializing in research and development and production of laser equipment, has been revolutionizing the industry with their cutting-edge innovations since 2006.The company offers a wide range of laser equipment including Fiber Laser Welding Machines, Laser Cutting Machines, and Laser Marking Machines. These machines are designed to cater to the diverse needs of various industries such as automotive, aerospace, and electronics, to mention a few.Fiber Laser Welding MachinesFiber Laser Welding Machines from Suzhou Suntop Laser Technology Co., Ltd. are the perfect solution for industries that require high precision and consistent welding results. These machines are designed to work with a wide range of materials such as stainless steel, aluminum, titanium, and copper.One of the most significant advantages of Fiber Laser Welding Machines is that they offer a high degree of control and precision in welding. This makes them ideal for welding small, detailed parts as well as larger, bulkier components. Additionally, Fiber Laser Welding Machines also offer a faster welding speed than traditional welding methods, making them a much more efficient choice for large-scale production.Laser Cutting MachinesSuzhou Suntop Laser Technology Co., Ltd. also offers Laser Cutting Machines designed to deliver unmatched precision and accuracy. These machines can handle cutting a wide range of materials, including metal, wood, and plastics of varying thickness.One of the most significant advantages of Laser Cutting Machines is their ability to perform intricate cuts that are not possible with traditional cutting methods. These machines are also capable of cutting thicker materials more efficiently than other methods.The Laser Cutting Machines from Suzhou Suntop Laser Technology Co., Ltd. are also designed to be user-friendly, with easy-to-use software and intuitive controls. This makes them an ideal choice for businesses looking to increase their production while reducing their operating costs.ConclusionSuzhou Suntop Laser Technology Co., Ltd. has been redefining the laser industry since 2006, with their state-of-the-art Fiber Laser Welding Machines and Laser Cutting Machines. The high degree of control and precision these machines offer make them an ideal choice for industries that require high accuracy and consistency in their operations.From automotive to aerospace, electronic devices to medical equipment, Fiber Laser Welding Machines and Laser Cutting Machines from Suzhou Suntop Laser Technology Co., Ltd. offer unmatched precision and efficiency. With their advanced technology and user-friendly designs, these machines are becoming increasingly popular with businesses looking to enhance their production capabilities while reducing their operating costs.

Advantages of CO2 Laser Cutting Services for High Precision and Diverse Materials Cutting

and Precision Waterjet.CO2 Laser Cutting Services for High-Accuracy and PrecisionCO2 laser cutting services have been gaining popularity in recent years due to their versatility, accuracy, and efficiency. With the help of specialized equipment and advanced technology, CO2 laser cutting services can produce precise and intricate cuts on various materials without the risk of deformities or damage.The CO2 laser cutting process involves the use of a focused beam of laser light to cut through the material. The laser beam is generated by a CO2 laser cutting head, which directs the laser beam onto the material to cut. The process may vary depending on the type, thickness, and complexity of the material, but CO2 laser cutting services can produce high-quality cuts on almost any material, from metals and plastics to ceramics and glass.Precision Waterjet is a leading provider of CO2 laser cutting services, offering a wide range of materials cutting capabilities for various industries, including aerospace, automotive, electronics, and medical devices. With a highly skilled team and state-of-the-art equipment, Precision Waterjet delivers precision and accuracy in every project, ensuring customer satisfaction and meeting the tightest tolerances.Advantages of Precision CO2 Laser Cutting ServicesPrecision Waterjet's CO2 laser cutting services offer several advantages over traditional cutting methods, such as plasma or torch cutting, stamping, or manual cutting. Here are some of the benefits of choosing Precision Waterjet for your CO2 laser cutting needs:• Higher Accuracy and Precision: CO2 laser cutting is a highly accurate and precise cutting method, which makes it ideal for producing intricate designs and complex shapes. With Precision Waterjet's advanced technology and precise control, you can achieve the desired shape with exceptional accuracy and sharpness.• Better Edge Quality: Compared to plasma or torch cutting, CO2 laser cutting produces a smoother and cleaner edge, with no dross or slag. This results in a high-quality finish that requires minimal post-processing, saving time and costs.• Diverse Materials Cutting Capability: CO2 laser cutting is a versatile cutting method that can cut through a wide range of materials, from metals and plastics to wood and glass. Precision Waterjet's CO2 laser cutting services can handle materials of different thicknesses and densities, providing exceptional results for any application.• Lower Tooling Cost: CO2 laser cutting requires minimal tooling, reducing the total production cost and lead time. With Precision Waterjet's efficient and precise cutting technology, you can save on tooling costs while maintaining high-quality results.• Large Production Runs: CO2 laser cutting is ideal for large production runs, as it can cut multiple pieces at once with exceptional precision and speed. Precision Waterjet's automated laser cutting system can handle high-volume production orders, ensuring consistent quality and timely delivery.In conclusion, Precision Waterjet's CO2 laser cutting services offer a reliable and cost-effective solution for your cutting needs. With their advanced technology, skilled team, and commitment to quality, Precision Waterjet can deliver precise and intricate cuts on a broad range of materials, setting new standards in the industry. To learn more about Precision Waterjet's CO2 laser cutting services, visit their website or contact their team today.

High-precision Metal Laser Cutting Services for CNC Machines

In today's rapidly evolving manufacturing industry, the demand for efficient and precise metal cutting technology is constantly on the rise. As a response to this demand, [Company Name] has introduced its cutting-edge CNC metal laser cutter, promising to revolutionize the way metal fabrication is done.The [Company Name] CNC metal laser cutter is equipped with the latest technology in laser cutting, allowing for high-speed cutting of various metals with exceptional precision. This cutting-edge machine is designed to meet the demands of a wide range of industries, from automotive and aerospace to electronics and construction. With its advanced features, the CNC metal laser cutter offers unparalleled flexibility and efficiency in metal cutting, making it an ideal solution for both large-scale industrial production and small-scale fabrication needs.One of the key features of the [Company Name] CNC metal laser cutter is its ability to seamlessly integrate with computer-aided design (CAD) software, allowing for precise and intricate designs to be translated into high-quality metal cuts. This not only streamlines the production process, but also ensures consistent and accurate results, regardless of the complexity of the design.Moreover, the [Company Name] CNC metal laser cutter is equipped with advanced safety features to protect operators and maintain a safe working environment. With its automated cutting process, the machine minimizes the risk of human error, while its enclosed cutting area and exhaust system effectively manage fumes and emissions.In addition to its advanced technology, the [Company Name] CNC metal laser cutter is also known for its low energy consumption and minimal maintenance requirements, making it a cost-effective and environmentally friendly solution for metal cutting needs. This further solidifies its position as a cutting-edge and sustainable option for modern manufacturing processes.With an unwavering commitment to innovation and customer satisfaction, [Company Name] has established itself as a leading provider of metal fabrication solutions. The introduction of the CNC metal laser cutter is a testament to the company's dedication to delivering cutting-edge technology that meets the evolving needs of the manufacturing industry.As the demand for efficient and precise metal cutting continues to grow, the [Company Name] CNC metal laser cutter is poised to make a significant impact on the industry. Its advanced features, seamless integration with CAD software, and commitment to safety and sustainability position it as a top choice for manufacturers seeking to optimize their metal cutting processes.The [Company Name] CNC metal laser cutter has already garnered positive attention from industry professionals, with early adopters praising its performance, reliability, and ease of use. As it continues to gain traction in the market, the CNC metal laser cutter is expected to become a staple in manufacturing facilities around the world.In conclusion, the introduction of the [Company Name] CNC metal laser cutter represents a significant milestone in the advancement of metal cutting technology. With its cutting-edge features, commitment to safety and sustainability, and seamless integration with CAD software, this machine is set to redefine the way metal fabrication is done. As the manufacturing industry continues to evolve, [Company Name] remains at the forefront, delivering innovative solutions that meet the needs of modern manufacturers.

Laser Cutting Machines in China: The Latest Innovations and Efficient Performance Unveiled by Industry Leader

China's Laser Cutting Industry Revolutionizes Manufacturing SectorThe rapid advancement of technology has significantly transformed the manufacturing landscape, with new innovations constantly revolutionizing industries around the world. Among the most groundbreaking developments in recent years is the emergence of computer numerical control (CNC) laser cutting machines, which have transformed the precision cutting process in various sectors.China, known for its thriving manufacturing industry, has witnessed significant growth in the CNC laser cutting sector. The industry has expanded rapidly, thanks to the continuous efforts of companies such as China Laser Cutting Solutions (CLCS), a leading player in the market. With its robust portfolio of technologically advanced CNC laser cutting machines, CLCS has propelled China's manufacturing sector into new heights.Founded in [year], CLCS has established itself as a trusted name in the field of CNC laser cutting machines. The company's cutting-edge technology, combined with its commitment to innovation, has set it apart from its competitors. CLCS specializes in the production of high-quality CNC laser cutting machines that enable precision cutting across various materials, including metals, plastics, and ceramics.One of the key factors fueling CLCS's success is its emphasis on research and development (R&D) activities. The company has invested significantly in advanced R&D facilities, fostering a culture of continuous innovation. This has allowed CLCS to consistently introduce state-of-the-art CNC laser cutting machines that cater to the diverse needs of companies operating across multiple industries.Furthermore, CLCS places great importance on ensuring the reliability and durability of its CNC laser cutting machines. The company conducts rigorous quality control measures throughout the manufacturing process to guarantee the highest standards of performance and efficiency. CLCS's commitment to delivering cutting-edge technology has earned it a reputation as a go-to provider for precision cutting solutions.CLCS's CNC laser cutting machines offer numerous advantages over traditional cutting methods. The precision and accuracy achieved through laser cutting minimize material waste and improve efficiency, resulting in significant cost savings for businesses. Moreover, the flexibility provided by CNC technology allows for the customization of the cutting process, making it suitable for a wide range of applications and industries.China's manufacturing sector has greatly benefited from the adoption of CNC laser cutting machines. The precision and speed of these machines have revolutionized production processes across industries such as automotive, aerospace, electronics, and clothing. By streamlining manufacturing workflows and improving quality control, CNC laser cutting machines have contributed to China's reputation as a global manufacturing powerhouse.Furthermore, the demand for precision cutting solutions has increased exponentially due to the growing popularity of customization and personalization in consumer products. CNC laser cutting machines provide businesses with the capability to meet these ever-evolving demands efficiently and effectively.In addition to revolutionizing the manufacturing sector, CLCS is also committed to sustainable practices. The company's CNC laser cutting machines are designed to minimize energy consumption and reduce environmental impact. By prioritizing eco-friendly manufacturing methods, CLCS actively contributes to China's efforts to achieve a more sustainable future.Looking ahead, CLCS aims to continue its mission of driving technological advancements in the CNC laser cutting industry. The company plans to expand its product range, catering to the evolving needs of businesses across various sectors. CLCS's dedication to research and development ensures that it will remain at the forefront of the CNC laser cutting market, driving innovation and transforming the manufacturing landscape in China and beyond.In conclusion, China's CNC laser cutting industry, spearheaded by companies like CLCS, has significantly revolutionized the manufacturing sector. With its state-of-the-art CNC laser cutting machines and dedication to continuous innovation, CLCS has played a crucial role in propelling China's manufacturing capabilities to new heights. As the demand for precision cutting solutions continues to grow, CNC laser cutting machines will continue to reshape industries, driving efficiency, and meeting the evolving needs of businesses worldwide.

High Precision Laser Cutting System for Co2 Lasers: A Game-Changer in Manufacturing

Co2 Laser Cutting System Revolutionizes Manufacturing IndustryIn today's rapidly evolving manufacturing industry, technological advancements play a crucial role in enhancing efficiency and precision. One such innovation that has been making waves in the industry is the Co2 Laser Cutting System. This cutting-edge technology has revolutionized the way manufacturers cut and shape materials with unprecedented accuracy and speed.The Co2 Laser Cutting System is a high-powered, computer-controlled machine that utilizes a laser beam to cut, engrave, or etch complex designs on various materials such as wood, metal, plastic, and more. This state-of-the-art system is known for its ability to produce intricate and precise cuts, making it a preferred choice for industries ranging from automotive and aerospace to electronics and signage.One of the leading providers of Co2 Laser Cutting Systems is {Company Name}. The company has been at the forefront of delivering cutting-edge laser solutions to a wide range of industries for over a decade. With a strong emphasis on innovation and customer satisfaction, {Company Name} has established itself as a trusted partner for businesses seeking to elevate their manufacturing capabilities.The Co2 Laser Cutting System offered by {Company Name} is equipped with advanced features that set it apart from traditional cutting methods. Its high-speed precision cutting allows for efficient processing of materials, reducing production time and costs. Additionally, the system's computer-controlled capabilities enable complex designs to be executed with unparalleled accuracy, meeting the demands of even the most intricate projects.Furthermore, {Company Name}'s Co2 Laser Cutting System boasts a user-friendly interface, making it accessible to operators of varying skill levels. This ease of use, coupled with the machine's rapid deployment capabilities, ensures that businesses can seamlessly integrate the technology into their existing manufacturing processes without extensive downtime or retraining.The applications of the Co2 Laser Cutting System are diverse and extensive, making it a versatile asset for manufacturers across various industries. From creating precision components for machinery to customizing intricate patterns in architectural designs, the system's flexibility and precision make it an indispensable tool for businesses looking to elevate their production capabilities.One of the key advantages of the Co2 Laser Cutting System is its ability to cut a wide range of materials with exceptional precision. Whether it's cutting through thick metal sheets or engraving detailed patterns on delicate surfaces, the system's versatility makes it a go-to solution for businesses with diverse manufacturing needs.In addition to its cutting and engraving capabilities, {Company Name}'s Co2 Laser Cutting System is also equipped with safety features to ensure a secure working environment for operators. With built-in sensors and safety protocols, the system prioritizes the well-being of its users while delivering optimal performance.As the manufacturing industry continues to evolve, the demand for advanced cutting technologies like the Co2 Laser Cutting System is only expected to grow. With its ability to deliver superior precision, efficiency, and versatility, this innovative technology is poised to become a mainstay in modern manufacturing processes.{Company Name} remains committed to staying at the forefront of this technological revolution, continuously enhancing its Co2 Laser Cutting System to meet the ever-changing needs of the industry. With a dedication to innovation and customer satisfaction, {Company Name} is poised to lead the way in delivering cutting-edge solutions that empower businesses to thrive in the competitive manufacturing landscape.In conclusion, the Co2 Laser Cutting System offered by {Company Name} is a game-changer for the manufacturing industry, offering unprecedented precision, efficiency, and versatility. As businesses seek to elevate their production capabilities, this cutting-edge technology is poised to drive the next wave of innovation and progress in manufacturing.

High-Quality Servo Motors for CNC Machines: What You Need to Know

CNC Servo Technology Enhances Precision and Efficiency in ManufacturingIn today's highly competitive manufacturing industry, companies are constantly seeking ways to enhance the precision and efficiency of their production processes. One technology that has revolutionized the manufacturing industry is the CNC servo system. This advanced technology has significantly improved the accuracy and speed of machining operations, leading to higher-quality products and increased productivity.The CNC servo system, developed by (), is a cutting-edge technology that combines computer numerical control (CNC) with servo motor technology to control the movement of industrial machines with unparalleled precision. This system has been widely adopted by manufacturers across various industries, including automotive, aerospace, electronics, and medical devices, to streamline their production processes and achieve superior product quality.The servo motors used in the CNC servo system are known for their high torque, low inertia, and precise control capabilities. These characteristics make them ideal for controlling the movement of machine tools, such as lathes, mills, and routers, with extreme accuracy. The CNC servo system's ability to precisely control the speed, position, and torque of these machines has significantly improved the accuracy and repeatability of machining operations.Furthermore, the CNC servo system's advanced control algorithms and feedback mechanisms allow for real-time monitoring and adjustment of machine movements, ensuring consistent and precise machining results. This level of control and monitoring is essential for achieving tight tolerances and high surface finishes in the production of complex parts and components.In addition to improving precision, the CNC servo system has also enhanced the efficiency of manufacturing processes. The high-speed and precise movements enabled by the servo motors have reduced cycle times and increased throughput, ultimately leading to higher productivity and lower production costs. By utilizing the CNC servo system, manufacturers can now produce more parts in less time, making their operations more competitive in the global marketplace.Moreover, the CNC servo system's compatibility with various types of CNC machines and its seamless integration with existing manufacturing systems have made it a versatile and cost-effective solution for manufacturers looking to upgrade their production capabilities. Whether it's retrofitting an existing machine or implementing a new CNC system, the CNC servo technology offers a flexible and scalable solution for improving manufacturing performance.As a leading provider of CNC servo technology, () has been at the forefront of innovation in the manufacturing industry. With a rich history of developing cutting-edge motion control solutions, () has continuously pushed the boundaries of precision and efficiency in manufacturing. The company's commitment to research and development has resulted in the creation of advanced servo motor technology that is now widely used in CNC systems around the world.() has also been dedicated to providing comprehensive support and assistance to manufacturers looking to adopt CNC servo technology. From system design and integration to technical service and training, () has ensured that its customers can maximize the benefits of CNC servo systems in their production operations. This level of commitment has earned () a strong reputation as a trusted partner in the manufacturing industry.In conclusion, the CNC servo system has proven to be a transformative technology for the manufacturing industry, offering unparalleled precision and efficiency in machining operations. By combining the power of CNC with advanced servo motor technology, () has provided manufacturers with a competitive edge in delivering high-quality products while improving their productivity. As manufacturing processes continue to evolve, the role of CNC servo technology will undoubtedly be pivotal in driving the industry forward.

Advanced Technology for Efficient Pipe Processing: A Complete Guide

The pipe processing industry is a vital component of the global manufacturing sector, with a wide range of applications across various industries such as construction, automotive, oil and gas, and more. With an increasing demand for high-quality and precision-engineered pipes, () has emerged as a leading player in the pipe processing market, offering a diverse range of products and services to meet the needs of its customers.() is a renowned company that specializes in the processing and manufacturing of pipes for various industrial applications. With state-of-the-art facilities and advanced technological capabilities, the company has established itself as a reliable and innovative supplier in the industry. From cutting and shaping to welding and coating, () offers a comprehensive suite of services to cater to the diverse needs of its customers.The company's commitment to quality and excellence is evident in its stringent quality control processes and adherence to international standards. By leveraging the latest technologies and best practices, () ensures that its products meet the highest industry standards for strength, durability, and performance. This commitment to quality has earned the company a stellar reputation among its clients and peers in the industry.As a customer-centric company, () places a strong emphasis on understanding and fulfilling the unique requirements of its clients. With a team of experienced engineers and technicians, the company collaborates closely with its customers to develop customized solutions that address their specific needs. Whether it's a complex piping system for a large-scale infrastructure project or a specialized component for a niche application, () has the expertise and capabilities to deliver tailored solutions that exceed expectations.In addition to its strong focus on quality and customer satisfaction, () is also dedicated to sustainability and environmental responsibility. The company employs eco-friendly manufacturing processes and adopts responsible waste management practices to minimize its environmental footprint. By prioritizing sustainability, () aims to contribute to a greener and more sustainable future for the industry and the planet.Looking ahead, () is poised for further growth and expansion as it continues to innovate and diversify its product offerings. With a steadfast commitment to excellence, customer satisfaction, and sustainability, the company is well-positioned to seize new opportunities in the dynamic and evolving pipe processing market. Through strategic partnerships, investments in research and development, and an unwavering dedication to its core values, () is set to cement its position as a global leader in the industry.In conclusion, () is a leading force in the pipe processing industry, offering a comprehensive range of high-quality products and services to meet the diverse needs of its customers. With a focus on quality, innovation, customer satisfaction, and sustainability, the company is well-equipped to navigate the challenges and opportunities in the market and set new benchmarks for excellence. As the industry continues to evolve, () is committed to driving positive change and delivering value to its customers, stakeholders, and the community at large.

Top 80w Co2 Laser Engraving Machine Manufacturers and Suppliers in China

Oree, a China-based manufacturer, is leading the trend in the laser engraving machine industry with its innovative product: the 80W CO2 Laser Engraving Machine. This cutting-edge technology is revolutionizing the way that products are manufactured and engraved with precision.Oree has been able to achieve excellence in the industry by combining creativity with state-of-the-art technology, producing products that are both durable and user-friendly. The company’s goal is to supply its customers with first-class solutions that will enable them to achieve a beautiful and polished finish for their products.This revolutionary CO2 laser engraving machine has a power of 80W, making it one of the most powerful machines on the market. This power enables the machine to create precise cuts and etchings on a variety of surfaces such as wood, leather, plastic, acrylic, and metals.The Oree 80W CO2 Laser Engraving Machine is equipped with a high-precision motor system that ensures the machine operates smoothly with minimal vibration. This feature keeps the machine stable during the engraving process, allowing the user to create intricate designs with ease.The company has made user experience a top priority, and the Oree 80W CO2 Laser Engraving Machine is no exception. It has a user-friendly interface that can be operated with ease, making it a perfect option for both beginners and experts alike.Another feature that makes this machine stand out is its compatibility with a wide range of software. It is compatible with CorelDraw, AutoCAD, Adobe Illustrator, and many other software programs.The Oree 80W CO2 Laser Engraving Machine is also equipped with a powerful exhaust system that ensures that the workplace remains clean and safe. It also has a water cooling system that not only extends the lifespan of the laser tube but also enhances the accuracy and precision of the engraving process.Oree is known for its excellent customer service and support, and it is no different with their 80W CO2 Laser Engraving Machine. The company offers 24/7 support to its customers, making it a reliable option for businesses, hobbyists, and entrepreneurs alike.In conclusion, Oree has once again demonstrated its commitment to innovation and excellence with its 80W CO2 Laser Engraving Machine. This machine is a game-changer in the laser engraving industry, and its versatility, precision, and ease of use make it a perfect option for anyone looking to create beautiful and polished finished products. With Oree’s stellar customer service, there is no doubt that this machine will meet the needs of businesses, hobbyists, and entrepreneurs all over the world.

Upgrade Your CNC Machine with a High-Performance Servo Motor

As the manufacturing industry continues to embrace technological advancements, the use of Computer Numerical Control (CNC) machines has become increasingly popular. CNC machines are essential in creating products that require precision and accuracy for companies that are seeking to achieve high-quality production.A CNC machine is an automated piece of equipment that is used for cutting, drilling, and milling a range of materials such as metal, wood, and plastics. To maintain the level of precision required for the machine to operate successfully, it is vital to have the correct equipment, such as a servo motor.Servo motors are used in a range of automated machinery, including CNC machines, to control the position and speed of the device. The accuracy and responsiveness of servo motors ensure that the various components of the machine perform accurately and consistently, ensuring the production of high-quality products.Many servo motor brands are available in the market, each providing unique features, but one company that stands out from the rest is a leading provider of innovative motion control systems. The company has been in existence for several years, providing cutting-edge solutions for the manufacturing industry.The company's products are designed to boost productivity and efficiency. This is achieved through delivering advanced solutions that cater to the needs of a dynamic and evolving market. While there are numerous brands of servo motors in the market, the company's products stand out due to their quality, reliability, and precision.One of the company's leading products is a high-performance servo motor that has revolutionized the CNC machining industry. With this servo motor, CNC machine owners can enhance the accuracy of their machining operations, which helps them to cut down on waste and save on production time. The servo motor ensures that the machine is always responding to new data points, making it easier to maintain the quality of the production process.The servo motor has a range of functions that make it ideal for CNC machines. For instance, it can provide both speed and torque control, something that is imperative for ensuring the effectiveness of the machine's operations. The servo motor's torque control means that it will not continue to rotate beyond what's necessary, ensuring that the components remain intact, and the machine maintains its longevity.The servo motor's speed control is equally essential, as it allows for dynamic speed changes depending on the machining process's requirements. The servo motor can quickly adjust to any speed requirement essential for maintaining the accuracy of the machining process. This feature is essential, especially when working with materials that require differing speed ranges.In addition to its outstanding performance, the servo motor's design is crucial to its functionality and efficiency. The servo motor is compact and lightweight, with a low moment of inertia, which means that it can operate at high speeds without subjecting the machine's components to undue stress.The company's servo motor is designed to operate efficiently even under extreme conditions such as high temperatures or dirty environments. This translates to a reduction in maintenance and operational costs, making it an economical solution for the manufacturing industry.The servo motor's high degree of accuracy ensures that the CNC machine can produce high-quality products that meet the customers' specifications consistently. This is critical, especially for companies in industries such as automotive, aerospace, and medical equipment, which require strict adherence to quality standards.With the advent of Industry 4.0, the manufacturing industry has seen an increased integration of artificial intelligence and automation. As a result, a shift towards smart manufacturing has emerged, where machines can communicate with each other and make decisions based on data analytics. The servo motor from this leading provider is designed to integrate seamlessly with smart machine technology, ensuring seamless communication and data transfer.In conclusion, the manufacturing industry is evolving, and companies are continually seeking the latest technology to improve their productivity and efficiency. The CNC machine is an essential component of the manufacturing process, and a servo motor plays a crucial role in ensuring its accuracy and precision. The servo motor from this leading provider is a reliable solution designed to cater to today's manufacturing needs, and its superior performance makes it a worthy investment for anyone dealing with CNC machines.

Cutting Metal Processing Technology with CNC Machine - Stock Video

Machines.Laser Cutting: Advanced Metal Cutting TechnologyLaser cutting is an advanced metal cutting technology that has revolutionized various manufacturing industries. This technology has enabled manufacturers to create precise, intricate designs in a wide range of materials. Since its inception, laser cutting has become an essential process for many applications such as automotive, aerospace, defense, electronics, and medical devices.One of the major reasons why laser cutting is so popular is the precision it offers. Laser cutting machines use a high-powered laser beam to cut through metal with incredible accuracy. This allows manufacturers to create complex, intricate designs that can not be replicated using traditional cutting methods. The laser beam can also work with a range of materials including metals, plastics, wood, and ceramics.CNC Machines and Laser CuttingComputer Numerical Control (CNC) machines are a critical component of laser cutting technology. These machines are programmed to operate the laser cutter using pre-set parameters. CNC machines and laser cutting are highly compatible because they allow for detailed and accurate designs to be created in a short amount of time.CNC machines also allow for the creation of reproducible parts that are identical, regardless of the number of times they are produced. This makes the manufacturing process much more efficient, saving time and money in the long run.Metal Cutting with Laser CNC MachinesLaser cutting technology has significantly revolutionized the metal cutting process. Metal cutting with laser CNC machines offers a lot of advantages to manufacturers. Firstly, the cutting process is quicker and more precise compared to traditional cutting methods. Secondly, laser cutting does not produce any burrs or chips, making it ideal for high-precision applications. Thirdly, laser cutting provides superior edge quality with less surface contamination. As a result, finished products have a cleaner and smoother finish.ConclusionMetal cutting with laser CNC machines is an excellent example of how technology continues to positively impact manufacturing processes. By utilizing advanced laser cutting technology, manufacturers can achieve high-precision results, creating intricate designs, and reducing production time and cost. With CNC machines and laser cutting, reproducibility and consistency are also ensured, thereby enhancing the overall efficiency of the production process. By adopting this technology, manufacturers can deliver high-quality products that meet the strictest customer requirements.